Induction soldering: purpose, types, advantages and disadvantages

Induction brazing is a method of joining metal parts in which the mating is heated to a temperature higher than the melting temperature of the material used as solder and lower than the melting temperature of the parts themselves.

The filling of the gaps between the parts with molten solder and its diffusion penetration into the surface layers in the soldering zone, as well as the mutual dissolution of the metal of the parts and the solder ensure, after cooling the parts and crystallization of the solder, obtaining a mechanically strong and tight connection. Induction heating soldering is done with "hard" solders with a melting point above 550 °C and "soft" solders with a melting point less than 400 °C.

Brazing alloys provide higher strength in the brazing area. The most common in industrial practice is power soldering inductors from high frequency generators 2.5 khz — 70 khz and even industrial frequency current (50 hz).

When determining the possibility of using induction soldering, it is necessary to take into account the configuration of the seam, the material and mass of the sections connected by this method, the possibility of placing the inductor close to the seam and achieving uniform heating of the required section. The average size of the gap between the parts in the soldering area should be 0.05-0.15 mm.

According to the method of supplying parts to the inductor, dosing and heating differ:

-

manual soldering with fixing the part in the inductor and without fixing;

-

semi-automatic soldering;

-

automatic soldering in air with flux, as well as in reducing media, in vacuum and in inert gas without flux.

Both with direct heating of the workpiece and with indirect heating, soldering in gas environments and vacuum allows you to finally get suitable parts that do not require subsequent cleaning, processing and removal of flux.

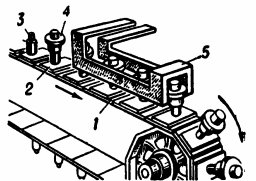

Scheme of a device for automatic soldering with continuous supply of parts to the inductor: 1 — conveyor belt; 2 — ceramic supports; 3 — mandrel for the tip for parts; 4 — parts for soldering; 5 — loop inductor.

Advantages of induction brazing:

1) less distortion and strapping of the product compared to other soldering methods, due to the zonal heating of the areas to be soldered;

2) the ability to quickly heat up the metal and solder deep seams due to the release of heat in the product itself;

3) high process productivity provided by concentration means power in a small volume, especially when using high frequency currents;

4) obtaining the same results due to the exact dose of energy transferred to the product;

5) the possibility of automating the soldering process and its implementation in the machining flow;

6) reduction of process costs (compared to soldering when heated by gas burners and in electric furnaces) with its high productivity;

7) improving and improving the working conditions of workers.

Disadvantages:

1) high costs of purchasing equipment;

2) the dependence of the shape of the inductor on the shape of the seam in the soldering area and the design of the part (each part requires a special inductor).

Induction brazing is used in the instrument, radio, electrical, engineering, etc. industries and is particularly useful for mass production of products.