Development of electric arc welding

History of arc welding

First practical application a rainbow in electric welding of metals obtained only in 1882, when N.N. Benardos created in St. Petersburg «Method of joining and separating metals by direct action of electric current», which he called «electrohephaestus».

According to the conclusion of academicians N. S. Kurnakov, O. D. Khvolson and others, the essence of this method is that the processed object is connected to one, and the coal to the other pole of the electric source and the voltage arc formed between the processed object and the coal produces an action similar to that produced by the flame of a blowtorch when metal is heated and melted. A special carbon or other conductive electrode is inserted into the holder and the arc is supported by hand.

In 1888 - 1890, the method of using the heat of an electric arc for welding metals was improved by mining engineer N.G.Slavyanov, who replaced the carbon electrode exclusively with a metal one and developed a semi-automatic device for supplying a metal electrode during its burning and maintaining the arc, which he called a "melter".

The essence of ways electric arc welding, created as a result of the work of talented engineers-inventors N.N. Benardos and N.G. Slavyanov, remains unchanged to this day and can be characterized as follows: the electric arc formed between the electrode and the connected parts of the product melts the base material of the product with its heat and melts the electrode supplied to the arc flame zone — a filler material that, in the form of drops of molten metal, fills the junction and fuses with the base metal of the product. In this case, the total heat generation of the arc is regulated by choosing a suitable mode, the main parameter of which is the current.

In practical application, numerous improvements have been made and are being made in the methods, which do not change the essence of the processes, but increase their practical value. The development of the created welding methods goes along with the development of the energy bases of welding technology in the direction of improving the quality and productivity of welding.

The main conditions that contributed to this development were:

-

ensuring stable operation of the arc;

-

obtaining appropriate quality and strength of the connection.

The first condition was met by creating energy sources with characteristics determined by the properties of an electric arc under welding conditions.

The arc, as the main source of heating and consumer of energy during welding, is characterized by a dynamic load, in which, at time intervals measured in hundredths of a second, sharp changes in the electrical regime appear in the arc circuit.

The melting of the electrode and the transfer of metal from the electrode to the workpiece causes sharp fluctuations in the length of the arc and repeated short circuits of the arc power source (up to 30 times per second) at very short intervals. In this case, the current and voltage do not remain constant, but have instantaneous changes from a certain value to a maximum and vice versa.

Such sudden changes in load disturb the equilibrium state of the electric arc system — current source… In order for the arc to burn for a long time at a certain value of the current, without extinguishing and not turning into other forms of electric discharge, it is necessary that the source of current supplying the arc quickly reacts to changes occurring in the mode of the arc and ensures its stable operation.

Early in the development of electric welding engineering, this was done with the help of incorporated ballast resistors to limit the current and sequentially calm the arc in the main circuit of the electrical machines. Subsequently, special power sources with falling characteristics and low magnetic inertia are created, which fully meet the requirements arising from the properties of the welding arc.

In parallel with the development of electric welding engineering, studies are carried out that allow to establish the main parameters of the static characteristics of the arc in welding conditions and to study the optimal conditions and the main electrical parameters of the energy sources and their influence on the stability and continuity of the burning of the arc during welding.

In the next period, based on the research of the statics and dynamics of the process in electric welding machines, a classification of welding machine systems and apparatus was developed and a unified generalized theory of welding machines was created.

Characteristics of the arc welding process

The process of electric arc welding is a very complex complex of physical, chemical and electrical phenomena that occur continuously at all stages in extremely short periods of time. Compared to conventional metallurgical processes of melting metals, the welding process is different:

-

small volume of the bath with molten metal;

-

high temperatures of metal heating, which at high speeds and local heating leads to high temperature gradients:

-

an inseparable connection between the applied metal and the base metal, the latter being, as it were, a form for the former.

Thus, the heated and molten metal in a small volume weld pool is surrounded by a significant mass of the lower temperature base metal. This circumstance, of course, determines the high rates of heating and cooling of the metal and, as a result, determines the nature and direction of the reactions taking place in the weld pool.

Passing through the arc gap, the molten additional metal is exposed to the atmosphere of the arc at very high temperatures, which leads to oxidation of the metal and absorption of gases from it, and activation of inert gases (mainly nitrogen) is observed in the arc, the activity of which is negligible in conventional metallurgical processes.

The molten metal in the weld pool is also exposed to an arc atmosphere, where physico-chemical reactions take place between the metal, its impurities and gases absorbed by it. As a result of these phenomena, the deposited weld metal has an increased content of oxygen and nitrogen, which, as is known, reduces the mechanical characteristics of the metal.

When a metal passes into an arc and remains in a molten state at the place of impurity in the iron, as well as alloying additions burn, which also deteriorates the mechanical properties of the metal. Gases formed during the combustion of impurities, as well as those dissolved in the metal during the solidification of the molten metal, can lead to the formation of voids and pores in the deposited metal.

Thus, the processes occurring during welding make it difficult to obtain high-quality weld metal. These difficulties turned out to be such that it was impossible to obtain a weld with characteristics close to the characteristics of the weld metal, which is the main indicator of the quality of welding, without taking special measures.

Improvement of arc welding technology

The main measure that increased the quality and strength of metal joints in existing arc welding methods was the use of special coatings — coatings on the electrodes.

In the initial period, the function of such coatings-coatings was to facilitate ignition and increase the stability of the arc due to their ionizing effect. Later, with the development of thick or high-quality coatings, the function of which, in addition to increasing the stability of the arc, is to improve the chemical composition and structure of the deposited metal, a significant increase in the quality of welding is observed.

The development of special coatings on electrodes has made it possible in recent years to spread the use of basic methods of welding and cutting metals underwater. In this case, the purpose of the coatings on the electrodes is also (due to their slower burning than the electrode) to maintain a protective shield around the arc and to form a bubble in which the arc burns with the gases released when the coatings burn.

Simultaneously with the improvement of the quality of the welded connection, an increase in welding productivity is observed, which in manual welding is achieved by increasing the power of the welding arc with a simultaneous increase in the diameter of the metal electrode. A significant increase in power and an increase in the size of electrodes led to the replacement of manual welding with automatic.

The biggest difficulties in automatic welding were posed by the issue of electrode coatings-coatings, without which high-quality welding under modern requirements is almost impossible.

A successful solution was to feed the coating of crushed granular flux not to the electrode, but to the base metal.In this case, the arc burns under a layer of flux, thanks to which the heat of the arc is used more efficiently, and the seam is protected from exposure to air. This addition was an improvement to the basic metal electrode welding process that greatly increased productivity and improved weld quality.

The ability to control the thermal state of the metals to be joined using modern sources of energy for the welding arc makes it possible to realize all transitional forms of the joining process from the plastic to the liquid, molten state of the materials. This circumstance opens up new possibilities for connecting not only different metals, but also non-metallic materials to each other.

With the improvement of technological welding processes, the strength and reliability of welded structures increase. In the initial period, when the welding process was carried out exclusively manually, electric arc welding was used in all types of restoration and repair work.

The importance of electric arc welding as one of the main and advanced technological processes at the moment is undeniable. Experience with the use of welding in various industries has clearly proven that this method of metalworking allows not only to save metal (25 — 50%), but also to significantly speed up the production of works of all types of metal structures.

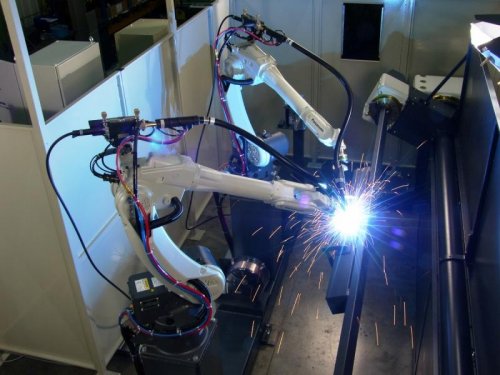

The development of mechanization and automation of the process, aimed at a continuous increase in productivity, combined with a steady increase in the quality and strength of welding, further expands the scope of its application.Currently, electric arc welding is the leading technological process in the production of all types of metal structures operating under static and dynamic loads at low and high temperatures.

Other interesting and useful articles about electric welding: