Power cord design

How power cords work

Power cables consist of the following basic elements: conductors, insulation, sheaths and protective covers. In addition to the main elements, the cable structure may include shields, protective earthings and fillers.

Power cables consist of the following basic elements: conductors, insulation, sheaths and protective covers. In addition to the main elements, the cable structure may include shields, protective earthings and fillers.

Power cables differ: according to the type of metal of the wires - cables with aluminum and copper wires, according to the type of materials that insulate current-carrying wires, cables with paper, plastic and rubber insulation, according to the type of protection of the insulation of cable wires from the influence of the external environment - cables of metal, plastic and rubber sheath, according to the method of protection against mechanical damage - armored and unarmoured, according to the number of cores - one-, two-, three-, four- and five-core.

Each cable design has its own designation and brand. The cable brand consists of the initial letters of the words describing the construction of the cable.

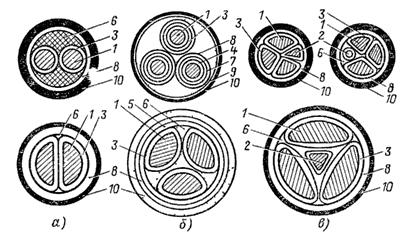

Rice. 1.Cross-sections of power cables: a-two-core cables with round and segmented conductors, b-three-core cables with belt insulation and separate sheaths, c-four-core cables with a zero conductor of circle, sector and triangular shape, 1 — conducting wire, 2 — neutral conductor, 3 — core insulation, 4 — shield on conductive core, 5 — belt insulation, 6 — filler, 7 — shield on core insulation, 8 — sheath, 9 — bumper, 10 — outer protective cover

Structural elements of power cables and their purpose.

The conductors of the power cables are made of aluminum and copper, single-wire and multi-wire. According to the shape, the veins are made round, sector or segmental (see Fig. 1).

Aluminum conductors of cables up to and including 35 mm2 are made single-wire, 50-240 mm2 - single-wire or multi-wire, 300-800 mm2 - multi-wire.

Copper wires up to 16 mm2 inclusive are made single-wire, 25 — 95 mm2 — single-wire or multi-wire, 120 — 800 mm2 — multi-wire.

The neutral conductor or the protective earth conductor, as a rule, has a reduced cross-section compared to the main conductors. It can be round, sector or triangular and is located in the center of the cable or between its main conductors (see Fig. 1).

A protective earth conductor is used to connect non-energized metal parts of an electrical installation to a protective earth circuit.

The insulation applied to the core of the cable is called the insulated conductor, and placed on top of the insulated twisted or parallel conductors of a multi-core cable is called the waist insulation.

Paper cable insulation impregnated with viscous impregnating compounds (oil rosin or electrical insulating synthetics).

The disadvantage of cables with a viscous impregnation composition is the extremely limited possibility of laying them on inclined routes, namely, the height difference between their end fittings should not exceed: for viscous-impregnated cables up to 3 kV, armored and without armor in an aluminum sheath — 25 m , without armor in lead sheath — 20 m, armored in lead sheath — 25 m, for cables with viscous impregnation 6 kV, armored and without armor in lead sheath — 15 m, in aluminum — 20 m, for cables with viscous impregnation 10 kV , armored and unarmored in lead and aluminum casing — 15 m.

Cables with a viscous impregnating compound, the free part of which has been removed, are called lean-impregnated cables. They are used when laying on vertical and inclined routes, without limiting the level difference, if these are unarmored and armored cables in an aluminum sheath for voltages up to 3 kV, and with a level difference of up to 100 m — for any other cables with depleted impregnated insulation.

The rubber insulation is made of a dense layer of rubber or of rubber strips with subsequent vulcanization. Power cables with rubber insulation are used in networks for alternating current up to 1 kV and direct current up to 10 kV.

Power cables with plastic insulation have insulation from polyvinyl chloride plastic in the form of a continuous layer or from polyethylene compositions. Self-extinguishing (self-extinguishing) and vulcanized polyethylene cables are also used.

Screens are used to protect external circuits from the influence of electromagnetic fields of currents passing through the cable and to ensure symmetry of the electric field around the cable cores. Screens are made of semiconducting paper and aluminum or copper foil.

Substitutes are necessary to eliminate the free gaps between the structural elements of the cable, to compact them, to give the necessary shape and mechanical stability to the cable structure. Bundles of paper tapes or cable yarns, plastic or rubber threads are used as fillers.

Substitutes are necessary to eliminate the free gaps between the structural elements of the cable, to compact them, to give the necessary shape and mechanical stability to the cable structure. Bundles of paper tapes or cable yarns, plastic or rubber threads are used as fillers.

Power cable sheaths… Aluminum, lead, steel corrugated, plastic and rubber non-combustible (nitrite) cable sheaths protect cable internals from damage by moisture, acids, gases, etc.

The aluminum sheath of supply cables for voltages up to 1 kV is permitted to be used as the fourth (neutral) conductor in four-wire AC networks with a solidly grounded neutral, except in installations with explosive atmospheres and installations in which the current in the neutral conductor under normal conditions is more than 75% of the current in the phase wire.

Protective covers of power cables... Since cable sheaths can be damaged and even destroyed by chemical and mechanical influences, they are covered with protective covers.

A cushion applied to the screen or casing to protect them from corrosion and damage from strips or bumpers. The cushion is made of layers of impregnated cable yarn, polyvinyl chloride, polyamide and other equivalent tapes, crepe paper, bituminous compound or bitumen.

To protect them from mechanical damage, the sheaths of the cables are wrapped, depending on the operating conditions, with a steel belt or a wire armor... The armor wire is made of round or flat wires.

The armor of flat steel strips protects the cables only from mechanical damage.Steel wire armor also absorbs tensile forces. These forces occur in cables when cables are laid vertically at great heights or along steeply inclined routes.

To protect the cable armor from corrosion, it is covered with an outer cover made of a layer of cable or glass yarn impregnated with a bitumen composition, and in some structures, pressed polyvinyl chloride or polyethylene hose bitumen is applied to the layers of yarn.

In mines, explosive and fire-hazardous rooms, it is not allowed to use armored cables of conventional design due to the presence of a "cushion" between the sheath and the armor of the cable containing combustible bitumen. In these cases, cables with a non-combustible "cushion" and an outer cover made of fiberglass staple yarn should be used.