Resistance welding machines and devices

Pressure welding

Pressure welding includes various welding methods in which the parts to be joined are compressed by mechanical force, due to which the continuity and strength of the joint is achieved.

Pressure welding includes various welding methods in which the parts to be joined are compressed by mechanical force, due to which the continuity and strength of the joint is achieved.

In the majority of cases, pressure welding is carried out by heating the parts to be welded in one way or another, and only in some special cases welding is achieved without heating (for example, cold welding, explosive welding). Of all pressure welding methods, electric resistance welding is the most common.

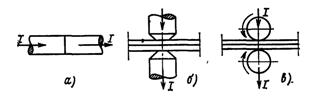

Contact or resistance welding is called the method of electric welding, in which heating occurs due to the predominant release of heat at the points of contact of the parts to be welded when an electric current flows through them (Fig. 1).

Rice. 1. The main types of resistance welding: a — frontal, 6 — spot, b — roller, I — direction of the welding current.

Welding resistance is characterized by a local concentration of heat power and therefore a high temperature in the region of the joint of the parts to be welded, which is due to the significant resistance of the contact of the joint compared to the resistance of the parts themselves. In this regard, resistance welding is a very economical and expedient type of welding.

Resistance welding can be carried out on both direct and alternating current, but in practice almost exclusively alternating current is used, since the currents required for welding on the order of thousands and even tens of thousands of amperes at voltages of a few volts can are most easily obtained with the help of transformers. dedicated DC sources for this purpose would be too expensive, difficult to manufacture and less reliable in operation.

Resistance welding can be carried out on both direct and alternating current, but in practice almost exclusively alternating current is used, since the currents required for welding on the order of thousands and even tens of thousands of amperes at voltages of a few volts can are most easily obtained with the help of transformers. dedicated DC sources for this purpose would be too expensive, difficult to manufacture and less reliable in operation.

Butt welding

In butt welding, the ends of the parts to be joined touch, after which a significant current passes through the parts, heating the joint to the temperature required for welding. The longitudinal compressive force then achieves direct connection continuity.

There are two types of butt welding: non-reflex welding (resistance welding) and re-welding.

In resistance welding, parts with machined ends are brought into contact and compressed with considerable force, then a current passes through the parts and due to the contact resistance of the junction, a concentrated release of heat occurs.

After reaching the temperature required for welding in the frontal zone, plastic welding of the parts to be joined is carried out under the influence of the pressing force.At the end of the welding cycle, the current is turned off and then the compressive force is released.

Resistance welding is usually carried out at a current density of 5-10 kA and a specific power of 10-15 kVA per 1 cm2 of the cross section of the welded parts. This type of welding is usually used to connect parts with small cross-sections (up to about 300 mm2).

Resistance welding is usually carried out at a current density of 5-10 kA and a specific power of 10-15 kVA per 1 cm2 of the cross section of the welded parts. This type of welding is usually used to connect parts with small cross-sections (up to about 300 mm2).

In butt welding with reheat, the heating of parts is carried out in three or two consecutive stages - preheating, flashing and final upset, or only in the last two stages.

At the initial moment of welding, the parts to be welded are in contact with a compression force of 5 — 20 MPa. Then the current is turned on, which heats the joints to 600 — 800 ° C (for steel), just as in butt welding without melting. After that, the pressure force is reduced to 2 — 5 MPa, as a result of which the contact resistance increases and, accordingly, the welding current decreases.

With the release of compression, the actual contact area of the ends of the parts decreases, the current rushes to a limited number of contact points and heats them to the melting temperature, and with further heating under these conditions, the metal overheats to the vaporization temperature at individual points.

Under the influence of excessive pressure, metal vapor is withdrawn from the welding contact zone and displaces liquid metal particles into the air in the form of a fan of sparks, and part of the molten metal flows in drops. Behind the destroyed protrusions, successive contact protrusions abut each other, creating new paths for the welding current to repeat the set effect.

This process of sequentially fusing the ends of the parts along the elementary ridges continues until the ends of the welded parts are covered with a continuous film of semi-liquid metal, after which a metallic continuity of the welded joint is created with relatively little disruptive force. In this case, the excess amount of molten metal is squeezed out of the contact in the form of a hole (rim).

The heating of the protruding ends of the welded parts is carried out mainly by heat conduction from the welding contact, where the temperature is of the greatest importance. The heating of the parts between the connecting and power supply electrodes due to the current flowing during the remelting process is very minor.

Adjusting the amount of energy delivered at a given contact resistance determined by the conditions of the welding process can be done either by changing the welding current or by changing the duration of the current flow.

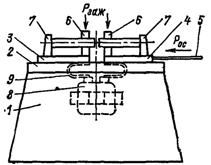

How the butt welding machine works is illustrated in fig. 2.

Rice. 2. Diagram of a butt welding machine: 1 — bed, 2 — guides, 3 — fixed plate, 4 — movable plate, 5 — feeding device, 6 — clamping device, 7 — limiters, 8 — transformer, 9 — flexible current conductor , Pzazh — tightening force of the products, Ros — disturbing force of the products.

Butt welding machines are classified as follows.

1. By welding method — for resistance welding and flashing (continuous flashing or heating flashing).

2. With advance registration — universal and specialized.

2. With advance registration — universal and specialized.

3. According to the design of the power mechanism — with a spring, lever, screw (from the steering wheel), pneumatic, hydraulic or electromechanical drive.

4.By arrangement of clamps — with eccentric, lever and screw clamps, and lever and screw clamps can be performed manually or mechanized with pneumatic, hydraulic or electromechanical drive.

5. According to the method of assembly and installation — stationary and portable.

Spot welding

In spot welding, the parts to be joined are usually located between two electrodes fixed in special electrode holders. Under the action of the pressure mechanism, the electrodes tightly press the parts to be welded, after which the current is turned on.

Due to the passage of current, the parts to be welded are quickly heated to the welding temperature and the greatest heat release occurs at the surfaces to be joined, where the temperature may exceed the melting temperature of the parts to be welded.

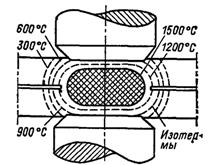

In fig. 3 shows the temperature distribution along the cross-section of the welded parts, characteristic of the final stage of steel welding.

Rice. 3. Temperature field in the last stage of spot welding

The highest temperature is observed in the central shaded part of the welding place - the core. The contact surface of the part that will be welded with an electrode (usually with water cooling) is heated to a relatively low temperature, but in the presence of a liquid or semi-liquid core and an adjacent plastic metal core, the compressive force of the electrodes causes indentations on the surface of the welding workpieces.

The core temperature at the weld point is usually slightly higher than the melting point of the metal.The diameter of the molten core determines the diameter of the weld spot, usually equal to the diameter of the contact surface of the electrode.

The core temperature at the weld point is usually slightly higher than the melting point of the metal.The diameter of the molten core determines the diameter of the weld spot, usually equal to the diameter of the contact surface of the electrode.

The time for welding in one place depends on the thickness and physical properties of the material of the welded parts, the power of the welding machine and the pressure force. This time varies from thousandths of a second (for very thin color sheets) to several seconds (for thick steel parts). For a rough estimate, the time to weld one spot of mild steel can be taken as 1 s per 1 mm thickness of the welded sheet. The rate of heating of the metal to the welding temperature depends significantly on the intensity of heat release.

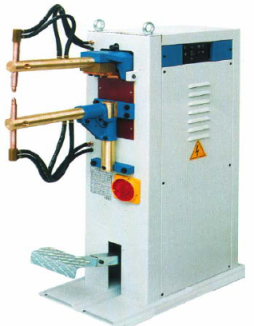

Spot welding machine

Roll welding

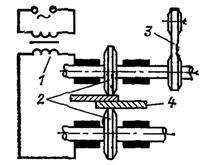

In this type of welding, the connection of parts with a continuous or discontinuous seam is carried out by passing through the parts to be welded, fed by means of rotating rollers (Fig. 4).

Rice. 4. The principle of roller welding: 1 — welding transformer, 2 — roller electrodes, 3 — roller drive, 4 — welded parts

In the nature of the process, roll welding is similar to spot welding. Roll welding is often referred to as seam welding, which is strictly speaking incorrect, as the seam welding concept can be extended to almost all types of welding.

Roller welding machines are usually equipped with two power supply currents, one of which is driven and the other rotates due to friction when moving the parts to be welded.

Roll welding is most often used to connect thin-walled parts, for example, in the manufacture of fuel tanks and barrels for transporting various materials.

There are three modes of roller welding.

1. Continuous movement of the welded parts relative to the rollers with a continuous supply of current. This method is used when welding parts with a total thickness of no more than 1.5 mm, because with large thicknesses, the joint coming out from under the rollers, being in a plastic state, can break due to delamination. In addition, with a continuous supply of current, a significant distortion of the welded parts takes place.

2. Continuous movement of the welded parts relative to the rollers with intermittent current supply. This most common method produces seams with little distortion in products with lower energy consumption.

3. Intermittent movement of the welded parts relative to the rollers with interrupted current supply (step welding).

Roll welding is very effective in the production of thin-walled vessels, in the production of welded metal pipes and a number of other products.

The main elements of roller machines are the bed, the upper and lower arms with roller electrodes, a compression mechanism, a roller drive and a welding transformer with a flexible current wire.

The main elements of roller machines are the bed, the upper and lower arms with roller electrodes, a compression mechanism, a roller drive and a welding transformer with a flexible current wire.

Transformers of roller machines work in intensive mode with PR = 50 — 60%, which requires enhanced cooling of their windings.

Roller welding machines are divided: according to the nature of installation — to stationary and mobile, according to purpose — to universal and specialized, according to the location of the rollers relative to the front of the machine — for transverse welding, for longitudinal welding and universal with the possibility of moving the rollers. for the location of the rollers relative to the product — with two-sided and one-sided arrangement, according to the method of rotation of the rollers — with a drive for one roller, with a drive for both rollers, with one upper roller, moving along a fixed bracket, and with one roller and a movable lower mandrel, according to the device of the compression mechanism — lever-spring, driven by an electric motor, pneumatic and hydraulic, according to the number of rollers — in single-roller, double-roller and multi-roller.

The power of the most common roller machines is usually 100 — 200 kVA. Similar to the spot welding of thin parts, it can be carried out by pulses of the discharge current of the capacitor, for which different types of roller machines are manufactured.