How to protect yourself from overvoltage

Modern electrical equipment must receive electrical energy with certain parameters in a reliable and safe way.

The civilized development of society makes people more dependent on various electrical and electronic devices, whose resistance to accidental voltage increase is not great.

Surge in an electrical product (device) — a voltage between two points of an electrical product (device), the value of which exceeds the highest value of the operating voltage. (GOST 18311-80).

Overvoltage can be caused by:

-

switching on and off high-power consumers, especially capacitive or inductive;

-

atmospheric discharge directly into the electrical supply network of the facility or near the facility (atmospheric overvoltage);

-

penetration of surge waves from other equipment (for example, water pipes) into the electrical wiring;

-

electrostatic discharge between devices.

In the event of a direct lightning strike in the power supply network or indirectly through induction, overvoltage in some wires inside the house it can reach a level of several kV to several tens of kV, and the surge resistance of modern electronic devices does not exceed 1.5 kV.

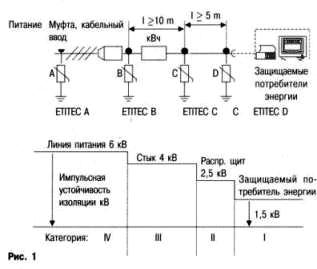

Existing technical standards oblige the use of lightning protection systems in construction. The European standard 1EC 664A divides electrical wiring into four overvoltage categories: IV, III, II and I (Fig. 1).

Each of these categories corresponds to a certain level of required impulse insulation resistance (in kV). This applies to both the wires and the connected electrical devices.

Separation of electrical wiring into overvoltage categories

Category IV — applies to devices located in the first part of the wiring: power lines on the main boards, for which the impulse resistance of the insulation must be at least 6 kV (due to the direct risk of atmospheric overvoltage or other types of overvoltage).

Category III — applies to devices and parts of electrical wiring (eg connections) threatened: atmospheric overvoltage reduced by surge breakers (type A) installed in the first part of the wiring; Protected energy consumers ETITEC D — overvoltage from switching on and off high-power electrical devices.

Category II - applies to devices fed by switchboards exposed to the risk of atmospheric surges, reduced by fire injuries from type B readers.

Category I. — refers to those parts of the wiring in which the level of overvoltage is determined by type C arresters.

Owners of valuable equipment (eg information equipment) should be aware of the risk of overvoltage and take precautions.

ETITEC varistor voltage limiters are modular devices that protect electrical wiring from the effects of overvoltages, both atmospheric and resulting from on-off.

The most important element of the limiter is a varistor. A varistor is a tablet rheostat made of zinc oxide (ZnO), a metal-ceramic alloy whose resistance is non-linear and highly dependent on the voltage across its terminals. It has very high resistance for low (about 275V) nominal voltage and very little for voltage of the order of several tens of kV.

During normal operation of the limiter, the varistor element is constantly under voltage in the network. Due to the aforementioned high resistance for low voltage, the current flowing through the varistor (called leakage current) is very small (not more than 0.5 mA). The protective activity of this element consists in passing the discharge current to the ground after reaching a voltage at its terminals equal to its ignition voltage.

The time required for the limiter to act from the moment the ignition voltage is applied is several tens of nanoseconds. The short response time of varistor arresters is an advantage over spark gaps. After triggering and passing discharge, the current limiter varistor for a very short return time rises to an insulating state, preventing the flow of subsequent current.

Varistor elements allow parallel connection in order to increase the load current capacity of overall limiters, which is also their major advantage.Each limiter has a thermal fuse, which in case of exceeding the permissible current flowing during normal operation, turns off the varistor, creating an open circuit in the electrical circuit in which it operates.

Classification of ETITEC surge arresters

According to VDE 0675, ETITEC varistor voltage limiters are divided into the following groups, depending on the function and place of installation, as well as the required level of protection:

-

A — limiter with a clamp for a line (cable) without insulation;

-

B — limiter with a double clamp, insulation breakdown on both sides — up to 95 mm2;

-

C — limiter with a linear clamp in vide conductors with insulation AsXSn with a length of 16 mm2 — 200 mm;

-

D — arrester with a double clamp, insulation breakdown on one side — up to 95 mm2;

-

E — limiter without bracket, bolt with M8 thread.

Group A — ETITEC A. Limiters of this group are designed to protect low-voltage devices and networks from overvoltage resulting from the penetration of discharges into objects located near overhead power lines or directly in the line at a great distance from the place of installation of these limiters.

Limiters are installed in accordance with the relevant standards outside the sites — on poles, especially in places where the overhead line passes into the cable line and the impulse voltage should not exceed 6 kV. more than 10 mm2 (Cu) and 16 mm2 (AI), and these sections should be as short as possible.

Circuit breakers installed in lines are recommended to be placed at the grounding points of the PE conductor or the neutral grounding conductor — PEN.In other cases, you need to make a grounder to which you need to connect the PE or PEN wire to which the arrester's ground clamp is connected. Electrical resistance overvoltages should not be higher than 10 ohms.

Group B — ETITEC B. Group B limiters are the first stage of protection inside the building. They are designed to limit surges resulting from:

-

discharge currents during a direct lightning strike to an object;

-

near shock or direct shock to the power line of the object — air or cable — low voltage;

-

atmospheric overvoltage induction.

Their main task is to limit overvoltages to the level of insulation resistance of receivers up to shock voltage — 4 kV, as well as discharge to the grounding electrode of electrical energy released during a direct lightning strike in the power supply network. When ETITEC B arresters are used, there is no need for any protective intervals -Varistor arresters, during the passage of a large current (extinguishing the shock wave), do not lead to arc surges, as is the case with spark plugs.

Group C — ETITEC C. The main task of the protectors of group C (second stage of protection) is to reduce the overvoltage passed through the limiters of group B, the value of which is still high for the protected devices.

Limiters must be connected in distribution boards in the places of distribution of electrical wiring. They can also be connected at the junction or in the main switchboard (as the first stage of protection) in installations where two-stage protection is not required, i.e.The permissible overvoltage level that can withstand the insulation of the receivers in the connection area of the ETITEC C limiter must be no more than 2.5 kV.

This type of arrester is primarily intended for installations where a low current (about 0.3 mA) is required through the arrester at rated voltage Unknown leakage current.

Group D — ETITEC D. Group D circuit breakers are designed for precision protection of consumers who are particularly sensitive to short-circuit surges and whose insulation resistance does not exceed 1.5 kV. They are also needed to protect the devices in case the distance between the group C limiter and the receiver is too great (over 15 meters).

Group D arresters must work together with Group B and C arresters together in a multi-level protection system and be suitable for mounting on a TN35 bus (DIN bus).

Varistor surge arresters designed for long-term service — maintenance-free. Under nominal conditions, the duration of the limiters is set at 200 thousand hours, and during this period they can be triggered countless times.

Elements for remote signaling of varistor element failure as a result of overvoltage when certain nominal values are exceeded have been added to the limiters. The ability to remove the varistor stack from the base of the arrester is an advantage of these arresters over locked ones.