Classification of premises according to environmental conditions

The normal operation of electrical installations depends on various environmental factors. Electrical networks and electrical equipment are affected by ambient temperature and sudden changes in it, humidity, dust, steam, gas, solar radiation. These factors can change the service life of electrical equipment and cables, worsen their working conditions, cause accidents, damage and even destruction of the entire installation.

The normal operation of electrical installations depends on various environmental factors. Electrical networks and electrical equipment are affected by ambient temperature and sudden changes in it, humidity, dust, steam, gas, solar radiation. These factors can change the service life of electrical equipment and cables, worsen their working conditions, cause accidents, damage and even destruction of the entire installation.

The electrical properties of insulating materials depend especially on the environmental conditions, without which no electrical device can do. Under the influence of climate and even weather changes, these materials can quickly and significantly change and, under critical circumstances, lose their electrical insulating properties.

The influence of adverse environmental factors on electrical equipment must be taken into account in the design, installation and operation of electrical installations.Requirements for protection of electrical equipment and cable products from adverse factors during storage, installation and operation are set out in PUE and SNiP.

Depending on the nature of the environment and the requirements to protect electrical installations from their effects, PUE distinguishes between indoor and outdoor installations. In turn, indoor facilities are divided into dry, humid, humid, especially humid, hot, dusty, with a chemically active environment, fire-hazardous and explosive, and outdoor (or open) installations — into normal, fire-hazardous and explosive. Electrical installations protected only by sheds are classified as outdoor.

Rooms in which the relative humidity does not exceed 60% are considered dry. If in such rooms the temperature does not exceed 30 ° C, there is no technological dust, active chemical medium, fire and explosive substances, then they are called rooms with a normal environment.

Wet rooms characterized by a relative air humidity of 60 ... 75% and the presence of steam or condensing moisture, which are released temporarily and in small quantities. Most electrical equipment is designed to work at a relative humidity that does not exceed 75%, therefore, in dry and humid rooms, use electrical equipment in the normal version. Wet rooms include pumping stations, production workshops where the relative humidity is maintained within 60 ... 75%, heated basements, kitchens in apartments, etc.

In wet rooms, the relative humidity exceeds 75% for a long time (for example, some metal rolling shops, cement plants, sewage treatment plants, etc.).If the relative humidity in the premises is close to 100%, that is, the ceiling, floor, walls, objects in them are covered with moisture, then these premises are classified as particularly humid.

In some branches of metallurgy and other industries (for example, in foundries, thermal, rolling and blast furnaces), the air temperature exceeds 30 ° C for a long time. Such rooms are called hot... At the same time, they can be wet or dusty.

Dusty Consider rooms in which, according to production conditions, technological dust is formed in such an amount that it settles on wires, penetrates into machines, devices, etc.

Distinguish between dusty rooms with conductive and non-conductive dust. The dust, which is not conductive, does not deteriorate the quality of the insulation, but favors its moistening and parts of electrical equipment under voltage due to its hygroscopicity.

In rooms with a chemically active environment, according to production conditions, vapors are constant or long-lasting or deposits are formed that destroy insulation and live parts of electrical equipment.

Flammable refers to premises where flammable substances are used or stored. According to the degree of fire danger, they are divided into three classes: P-I, P-P, P-Pa. The first class includes rooms in which flammable liquids are used or stored, the second class includes rooms in which, according to the conditions of production, suspended combustible dust is released that does not form explosive concentrations, and the last class includes rooms where solid or fibrous fuels are stored and use substances that do not form air mixtures.

Flammable refers to premises where flammable substances are used or stored. According to the degree of fire danger, they are divided into three classes: P-I, P-P, P-Pa. The first class includes rooms in which flammable liquids are used or stored, the second class includes rooms in which, according to the conditions of production, suspended combustible dust is released that does not form explosive concentrations, and the last class includes rooms where solid or fibrous fuels are stored and use substances that do not form air mixtures.

Explosive are premises in which, according to the production conditions, explosive mixtures of flammable gases or vapors with air, oxygen or other gases — oxidizers of flammable substances, as well as mixtures of flammable dusts or fibers with air can be formed when they pass into suspended state.

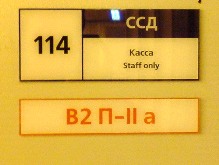

Explosive installations according to the degree of danger of using electrical equipment, they are divided into six classes: B-I, B-Ia, B-I6, B-Ig, B-II and B-IIa. In installations of class B-I, according to production conditions, under normal technological conditions, short-term formation of explosive mixtures of flammable gases or vapors with air or other oxidizer may occur.

Class B-Ia includes installations in which explosive mixtures of vapors and gases can be formed only in case of accidents or malfunctions of technological equipment. For installations of class B-I6, only local formation of explosive concentrations of vapors and gases in the air in small volumes with reliably functioning ventilation is characteristic.

Outdoor installations that form dangerous explosive concentrations of flammable gases or vapors are classified as class B-Ig. In class settings Explosive concentrations of suspended combustible dusts B-II can be created during normal operation of technological equipment, and in installations of class B-IIa - only in case of accidents or malfunctions.

External installations in which flammable liquids or solid flammable substances are processed or stored (open warehouses with mineral oils, coal, peat, wood, etc.) are classified as fire-hazardous. P-III.

The premises are classified according to the highest explosion hazard class of the installations located in them.Aggressive, humid, dusty and similar environments not only worsen the working conditions of electrical equipment, but also increase the danger of electrical installations to the people who service them. Therefore, in PUE, rooms, depending on the possibility of injury to people from electric shock, are divided into three groups: with increased danger, especially dangerous and without increased danger.

The premises are classified according to the highest explosion hazard class of the installations located in them.Aggressive, humid, dusty and similar environments not only worsen the working conditions of electrical equipment, but also increase the danger of electrical installations to the people who service them. Therefore, in PUE, rooms, depending on the possibility of injury to people from electric shock, are divided into three groups: with increased danger, especially dangerous and without increased danger.

Most industrial premises are classified as hazardous premises, that is, they are characterized by the presence of moisture (relative humidity for a long time over 75%) or conductive dust, conductive floors (metal, ring, reinforced concrete, bricks), high temperature (for a long time over 30 ° C), as well as the possibility of simultaneous human contact with the metal structures of buildings connected to the ground, technological devices, mechanisms, on the one hand, and to metal casings of electrical equipment on the other.

Particularly dangerous premises are characterized by special moisture or the presence of a chemically active environment or two or more conditions of increased danger.

If there are no conditions in the premises that create increased or special danger, they are called premises without increased danger. V depending on the type of technological activity in the premises of different categories and the possibility of electric shock for people are determined by the nature of the operation of the electrical equipment used for a given environment, the types and methods of implementation of electrical networks.