Exports and installations for infrared heating animals

In agriculture, general-purpose incandescent lamps, incandescent lamps, tube emitters, and tube electric heaters (TEN) are used as sources of infrared radiation for heating animals.

In agriculture, general-purpose incandescent lamps, incandescent lamps, tube emitters, and tube electric heaters (TEN) are used as sources of infrared radiation for heating animals.

Incandescent lamps.

Incandescent lamps differ in voltage, power and design. The design of incandescent lamps depends on their purpose. The glass bulb, the diameter of which is determined by the power of the lamp, is reinforced with a special mastic at the base. On the base there is a screw thread for fixing in the socket, with which the lamp is connected to the network. Tungsten is used to make the filament of the lamp. To reduce the scattering of tungsten, the lamp is filled with an inert gas (eg argon, nitrogen, etc.).

The main parameters of the incandescent lamp:

• Nominal voltage,

• electrical energy,

• luminous flux,

• average burn duration.

General purpose incandescent lamps are available in 127 and 220 V.

The electrical wattage of incandescent lamps is specified as an average value for the rated voltage for which the lamp is designed. In agriculture, incandescent lamps with a power range of 40 to 1500 W are mainly used.

The luminous flux of an incandescent lamp is directly proportional to the electrical power of the lamp and the temperature of the filament; for lamps that have burned out 75% of their nominal service life, a reduction of the luminous flux by 15-20% of the initial value is allowed.

When using lighting lamps to heat animals, be aware that high levels of light can irritate animals.

The average burning time of an incandescent lamp is determined mainly by the sputtering of tungsten. For most general purpose incandescent lamps, the average burn time is 1000 hours.

Changes in the mains voltage compared to the nominal value will result in changes in the flux emitted by the lamp, as well as in the output and service life. When the voltage changes by ± 1%, the luminous flux of the lamp changes by ± 2.7%, and the average burning time by ± 13%.

Incandescent lamps with a reflective layer. To direct the radiation flow to a certain area, lamps are used with a mirror and a diffuse reflective layer, which is applied from the inside to the upper part of the bulb.

Heat-emitting lamps.

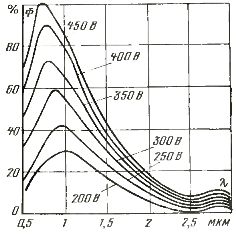

These radiation sources are "light" emitters consisting of a tungsten mono-coil and a reflector, which is the inner aluminized surface of the bulb with a special profile. The distribution curve of the radiation flux Ф (λ) along the spectrum for lamps of the IKZ type is shown in fig. 1.

Rice. 1.Distribution of the radiation flux along the spectrum of the IKZ 220-500 and IKZ 127-500 lamps.

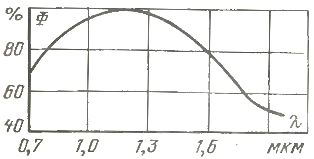

Rice. 2. Distribution of the radiation flux along the spectrum of the lamps IKZK 220-250 and IKZK 127-250.

In fig. 2 shows the radiation flux distribution curve along the spectrum of lamps of types IKZK 220-250 and IKZK 127-250.

In the designation of the type of lamps, the letters mean: IKZ — infrared mirror, IKZK 220-250 — infrared mirror with a painted bulb; the numbers after the letters indicate the mains voltage and the power of the radiation source. The lamp is a paraboloid glass bulb. Part of the surface of the lamp is covered from the inside with a thin reflective silver layer to concentrate the radiant flux in a given direction.

A very important parameter of glass bulbs, which affects the life of the lamps, is their heat resistance, that is, the ability to withstand sudden temperature changes. In order to increase heat resistance by changing the composition of the charge during glass melting, it is necessary to reduce its heat capacity and temperature coefficient of linear expansion, as well as to increase thermal conductivity.

A very important parameter of glass bulbs, which affects the life of the lamps, is their heat resistance, that is, the ability to withstand sudden temperature changes. In order to increase heat resistance by changing the composition of the charge during glass melting, it is necessary to reduce its heat capacity and temperature coefficient of linear expansion, as well as to increase thermal conductivity.

Depending on the shape of the bulb, the lamps have a different distribution of the radiation flow: either concentrated along the axis (with a parabolic bulb) or wide, at a solid angle of about 45 ° (with a spherical bulb). It should be noted the advantage of using lamps with a spherical bulb in agricultural production, these lamps provide a more uniform distribution of radiation in the heating zone.

A tungsten filament body is fixed inside the bulb. The filament material of the filament body evaporates in a vacuum, settling on the inside surface of the bulb and forming a black coating.This leads to a decrease in the light flux as a result of its more intensive absorption by the glass.

To increase the service life of the lamp and reduce the rate of evaporation of the filament body, the flask is filled with a mixture of inert gases (argon and nitrogen).

The presence of gas creates heat losses due to heat conduction and convection. In gas-filled lamps, the bulb is heated not only by radiation from the filament, but also by convection and conduction from the filling gas. So, heating the gas in a 500 W lamp consumes 9% of the energy supplied.

In powerful lamps with a massive filament body, the increase in heat loss through the gas is fully compensated by the sharp decrease in the dispersion of the filament, so they are always released with gas.

Unlike vacuum lamps, the temperature of individual sections of inert gas flasks depends on their operating position. For example, by turning the flask upside down, you can reduce the heating of the metal-glass junction from 383-403 to 323-343 K.

The radiation flux depends on the body temperature of the filament. An increase in temperature accelerates the evaporation of tungsten and increases the proportion of visible light in the radiation flux. Therefore, in lamps of the IKZ type, where infrared radiation is effective, the working temperature of the filament is reduced from 2973 K (as in an incandescent lamp) to 2473 K with a decrease in luminous efficiency of 60%. This allows conversion of up to 70% of the consumed electricity into infrared radiation.

Lowering the temperature of the filament made it possible to increase the service life of infrared lamps from 1000 to 5000 hours.The radiation of the incandescent body with a wavelength of more than 3.5 microns (7-8% of the total flux) is absorbed by the glass of the bulb, which is the reason for the frequent premature failures of the lamps due to temperature surges.

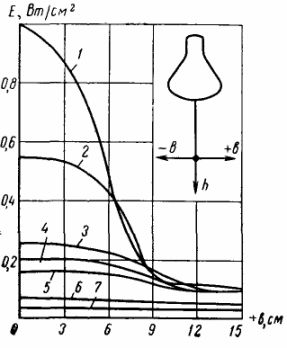

Irradiation from an IKZ type lamp at a distance of 50-400 mm to the heated surface varies from 2 to 0.2 W / cm2.

Diagrams of the energy radiation created by an infrared mirror lamp IKZ with a power of 250 W at a suspension height: 1 — 10 cm, 2 — 20 cm, 3 — 30 cm, 4 — 40 cm, 5 — 50 cm, 6 — 60 cm, 7 — 80 cm...

For heat transfer by radiation, ordinary incandescent lamps with a tungsten coil and a ball-shaped bulb can be used. The increase in radiation efficiency is provided by supplying voltage, the value of which is 5-10% less than the nominal; in addition, polished aluminum reflectors must be installed in the device.

Tube infrared emitters.

By design, tube sources of infrared radiation are divided into two groups — with heating bodies made of metal resistive alloys and tungsten. The first is a tube of ordinary or refractory glass with a diameter of 10–20 mm; Inside the tube, along the central axis, there is a body with a thread in the form of a spiral, to the ends of which a supply voltage is applied. Such emitters are not widely used. They are usually used for space heating.

By design, tube sources of infrared radiation are divided into two groups — with heating bodies made of metal resistive alloys and tungsten. The first is a tube of ordinary or refractory glass with a diameter of 10–20 mm; Inside the tube, along the central axis, there is a body with a thread in the form of a spiral, to the ends of which a supply voltage is applied. Such emitters are not widely used. They are usually used for space heating.

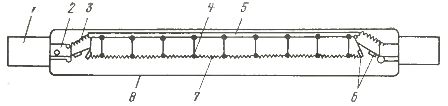

Tungsten filament emitters are similar in design to incandescent tube lamps. The heating body in the form of a tungsten spiral is located along the axis of the tube and is fixed on molybdenum holders soldered to a glass rod. A tube radiator can be made with an external or internal reflector formed by evaporating silver or aluminum in a vacuum. In fig.3 shows the construction of such an IR emitter.

The spectral distribution of radiation from tube emitters is close to that of tube emitters; the heating temperature is 2100-2450 K.

Rice. 3. Construction of a conventional tube IR source. 1 — base; 2 — rod; 3 — spring supporting the rod; 4 — holders for molybdenum; 5 — glass rod; 6 — electrodes; 7 — tungsten thread; 8 — glass tube.

Tubular radiators of low power (100 W) can be widely used in agriculture for heating young animals and poultry. So in France they are used to heat young poultry in cages. The radiators are installed directly on the ceiling of the cage, at a height of 45 cm and provide uniform heating for 40 chickens.

Tube lamps can be successfully used in the creation of combined irradiation and lighting installations for young farm animals and poultry, especially if we consider that UV lamps and lamps for erythema illumination also have a tubular design.

Quartz IR emitters.

Quartz IR emitters are similar to those described above, except that a quartz glass tube is used. Here we will limit ourselves to considering quartz IR emitters with tungsten heating elements.

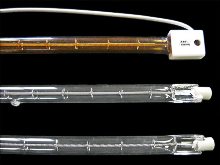

Rice. 4. Device for infrared lamp with filament type KI 220-1000.

Figure 4 shows the device of a quartz tube emitter — a lamp of the KI (KG) type. Cylindrical flask 1 with a diameter of 10 mm is made of quartz glass, which has maximum transmission in the IR spectral region. 1-2 mg of iodine are placed in a flask and filled with argon. The light body 2, made in the form of a monocoil, is mounted along the axis of the tube on tungsten supports 3.

The input to the lamp is carried out using molybdenum electrodes soldered into quartz legs 4. The ends of the filament spiral are screwed to the inner part of the sleeves 5. The cylindrical bases 6 are made of a nickel strip with a seam in which the outer molybdenum wires are welded 7. The temperature of the bases of the quartz emitters should not exceed 573 K. In this regard, it is mandatory that the radiators be cooled during operation in irradiating installations.

In combination with a mirror reflector in the form of an elliptical cylinder, quartz lamps create very high irradiance. If mirror lamps provide radiation up to 2-3 W / cm2, then radiation up to 100 W / cm2 can be obtained from a quartz lamp with a reflector.

In combination with a mirror reflector in the form of an elliptical cylinder, quartz lamps create very high irradiance. If mirror lamps provide radiation up to 2-3 W / cm2, then radiation up to 100 W / cm2 can be obtained from a quartz lamp with a reflector.

Quartz emitters with tungsten heating elements are produced by companies such as Osram, Philips, General Electric, etc. W for voltage 110/130 and 220/250 V. The life of these lamps is 5000 hours.

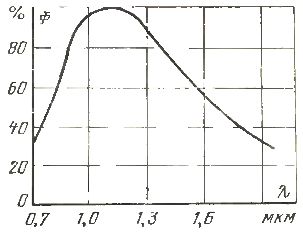

The distribution of the radiation energy of the KI-220-1000 lamp over the spectrum is shown in fig. 5. The spectral composition of the radiation generated by quartz lamps is characterized by the fact that there is a second maximum in the region of wavelengths greater than 2.5 microns, caused by radiation from a heated tube. Adding iodine to the bulb will reduce sputtering of the tungsten and thus increase the life of the lamp. In infrared quartz lamps, increasing the voltage above the nominal does not lead to a sharp decrease in the service life, which is why it is possible to smoothly adjust the radiation flux by changing the applied voltage.

Rice. 5. Distribution of the radiation energy spectrum of a KI 220-1000 type lamp at different lamp voltages.

Iodine cycle infrared quartz lamps have the following advantages:

• high specific radiation density;

• stability of the radiation flow during the operational life. The radiation flux at the end of life is 98% of the initial;

• small dimensions;

• ability to withstand long-term and large overloads;

• the ability to smoothly adjust the radiation flow in a wide range by changing the applied voltage.

The main disadvantages of these lamps:

• at sleeve temperatures above 623 K, quartz is destroyed by thermal expansion;

• The lamps can only be operated in a horizontal position, otherwise the incandescent body may deform under its own weight and the iodine cycle as a result of the concentration of iodine in the lower part of the tube will be disturbed.

Infrared lamps with an iodine cycle are used for drying paints and varnishes on various agricultural sites; for heating farm animals (calves, piglets, etc.).

Irradiators with infrared lamps.

To protect the infrared lamps from mechanical damage and water drops, as well as to redistribute the radiation flow in space, special fittings are used. The source of radiation together with the fixture is called the power supply.

Irradiators with various infrared lamps are widely used in animal husbandry for local heating of young farm animals and poultry.