Purpose and arrangement of synchronous machines

Synchronous machine - an alternating current machine in which the speed of the rotor at a constant frequency of current in the stator windings remains constant and does not depend on the magnitude of the load on the shaft of the machine.

Synchronous machine - an alternating current machine in which the speed of the rotor at a constant frequency of current in the stator windings remains constant and does not depend on the magnitude of the load on the shaft of the machine.

Synchronous machines They are mainly used to convert the mechanical energy of prime movers into electrical energy, that is, as generators of alternating current electrical energy. However, synchronous machines are also used in the modes of motors, reactive power compensators and other devices.

In industrial installations, three-phase synchronous machines are most widely used. Single-phase synchronous motors are used in electric drives of compressors, powerful fans, low-power motors in various automatic devices, etc.

Synchronous machine device

A three-phase synchronous machine consists of a stationary stator and an implicit or convex pole rotor rotating inside it, between them there is an air gap, the radial size of which is determined by the nominal power of the machine, its speed and varies from fractions to several tens of millimeters.

A three-phase synchronous machine consists of a stationary stator and an implicit or convex pole rotor rotating inside it, between them there is an air gap, the radial size of which is determined by the nominal power of the machine, its speed and varies from fractions to several tens of millimeters.

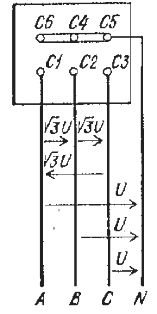

The stator of such a machine practically does not differ in design from the stator of an induction machine, it has a three-phase winding, the beginning of the phases of which are designated C1, C2, C3 and the ends - C4, C5, C6 and are brought to terminals with similar designations, which allows you to connect the phases of the stator winding with a delta or star.

The phases of the stator winding of a three-phase synchronous generator are mainly connected in a star, since this allows a three-phase four-wire network to have line and phase voltages that differ from each other by √3 times (Fig. 1).

Rice. 1. Scheme for connecting a three-phase four-phase network to the terminals of the stator winding of a three-phase synchronous generator when the phases are star-connected.

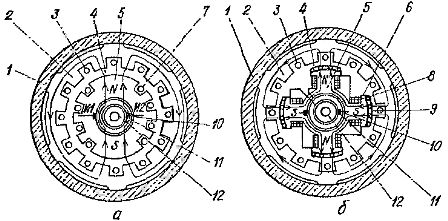

The rotor of a synchronous machine is a direct current electromagnetic system with a winding having the same number of poles as a three-phase stator winding. The magnetic lines of force are closed between the respective north and south poles of the rotor through the air gap and the supply line of the stator (Fig. 2, a, b).

The rotor winding or field winding is fed by a rectifier or a small DC generator—an exciter whose output is 0.5 to 10% of the rated output of a synchronous machine. The exciter can be located on the same shaft with a synchronous machine, driven from its shaft by a flexible transmission, or driven by a separate motor.

The implicit pole rotor of a synchronous machine is a solid or composite cylinder made of carbon or alloy steel with grooves milled across its surface in an axial direction. These slots contain a coil made of insulated copper or aluminum wire.The start of I1 and the end of I2 of this winding are connected to two slip rings mounted on an insulator sleeve located on the machine shaft and rotating with the rotor.

The fixed brushes are pressed against the rings, from which the wires are led to the clamps marked I1 and I2 for connection to a source of constant electrical energy. The large, non-slotted rotor cylinder teeth form the rotor poles.

An implicit pole rotor usually has two or four poles of alternating polarity, it is used in high speed synchronous machines, in particular in turbine generators - three phase synchronous generators directly connected to steam turbines designed for a speed of 3000 or 1500 revolutions per minute at AC frequency 50 Hz...

Rice. 2. The device of a three-phase synchronous machine with a rotor: a — hidden pole, b — prominent pole, 1 — frame, 2 — stator magnetic circuit, 3 — stator wires, 4 — air gap, 5 — rotor pole, 6 — pole tip, 7 — straight on the rotor, 8 — winding of the excitation coil, 9 — short circuit, 10 — slip rings, 11 — brushes, 12 — shaft.

The open-pole rotor of a synchronous machine with four or more poles has a solid or lined yoke of steel sheets, on which are attached steel posts of similar construction, with a rectangular cross-section, ending in spikes (Fig. 2, b). The coils connected to each other are located in the poles, forming an exciting coil.

Such a rotor is used in low-speed synchronous machines, which can be hydro-generators and diesel generators - respectively, three-phase synchronous generators directly connected to hydraulic turbines or internal combustion engines, designed for rotational speeds of 1500, 1000, 750 and lower rpm at an alternating current frequency of 50 Hz.

Many synchronous machines have on the rotor, in addition to the excitation winding, a short-circuited copper or brass damping winding, which in a non-smooth-pole rotor differs little from a similar winding on the rotor of an induction machine, and in a salient-pole rotor it is performed in the form of an incomplete a short-circuited coil, the bars of which are embedded only in the grooves and are absent in the interpole space. This winding contributes to the damping of rotor oscillations in non-stationary modes of a synchronous machine, and also provides asynchronous starting of synchronous motors.

Synchronous machines rated up to 5 kW are sometimes produced in reverse design with stator field winding and three-phase rotor winding.

Efficiency of a three-phase synchronous generator

The operation of three-phase synchronous machines in generator mode is accompanied by energy losses, which, but in their nature, are similar to losses in asynchronous machines. In this regard, the efficiency of a three-phase synchronous generator is characterized by the value of the coefficient of efficiency (efficiency), which under symmetrical load conditions is determined by the formula:

η = (√3UIcosφ) / (√3UIcosφ + ΔP),

where U and I — operating, network voltage and current, cosφ — the power factor of the receivers, ΔP — total losses corresponding to the given load of the synchronous machine.

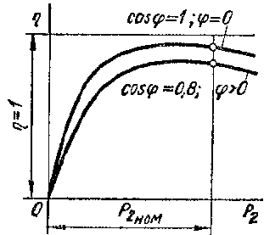

The value of efficiency (efficiency) of synchronous generators depends on the size of the load and the power factor of the receivers (Fig. 3).

Rice. 3. Graphs of the dependence of the efficiency of a three-phase synchronous generator on the load and the power factor of the receivers.

The maximum value of efficiency corresponds to a load close to the nominal one and is 0.88-0.92 for medium-power machines, and for high-power generators it reaches a value of 0.96-0.99. Despite the high efficiency of large synchronous machines, due to the large amount of heat generated, it is necessary to cool the windings with hydrogen, distilled water or transformer oil, which contributes to better heat dissipation, and also allows you to create more compact and efficient three-phase synchronous machines.