Methods of making soldered joints

Externally, the welding and soldering processes are very similar to each other. The main difference between soldering is the lack of melting of the base metal of the parts being joined. When soldering, only the filler material melts — solder, which has a lower melting point. The methods of obtaining solder joints are classified into several main types:

Externally, the welding and soldering processes are very similar to each other. The main difference between soldering is the lack of melting of the base metal of the parts being joined. When soldering, only the filler material melts — solder, which has a lower melting point. The methods of obtaining solder joints are classified into several main types:

1. By the method of removing the oxide film:

a) flux soldering. The use of flux allows you to clean the surfaces of the parts to be soldered from oxide films and protect them from subsequent oxidation. Flux is supplied by dispensers, manually, in the form of powders, pastes mixed with solder (tubular and composite solders).

b) ultrasonic soldering. Ultrasonic soldering uses cavitation energy to remove the oxide film. The ultrasonic waves emitted by the generator are transmitted to the heated tip of the soldering iron tip. Combined methods (with flux or abrasive) are also used. Ultrasonic soldering allows you to get welded joints even on the surface of glass and ceramics and is one of the most modern methods.

Ultrasonic soldering of glass

c) soldering in neutral (inert) or active gas with an admixture of hydrogen fluoride or hydrogen chloride. Such mixtures are called gas streams. The disadvantage of this method is the danger of explosion of the process.

d) soldering in an inert or neutral gas environment without impurities. Oxide films are removed by dissociation, dissolution and sublimation (transfer from solid to gas) of oxides from the part material and solder. When brazing in this way, a small amount of flux is often used to protect against oxidation before heating to the required temperature. The cooling of the soldered parts takes place in the same environment.

e) vacuum soldering. The vacuum container can be heated in two ways: from the outside and from the inside using heating elements. In this case, liquid and solid flows are not used; boron trifluoride, lithium, potassium, sodium, magnesium, manganese, calcium and barium vapors are used as gaseous streams. To increase the productivity of the soldering process, the vacuum chamber is purged with inert gases.

Desktop machine for vacuum soldering

2. According to the type of solder and the method of filling the soldered seam:

a) soldering with ready-made solder fed into the gap forcibly or with the help of built-in parts.

b) soldering with composite solder in the form of filler (granules, powder or fibers, embedded parts of porous mass or mesh).

c) contact-reactive and reactive-flux soldering. The parts are connected by contact-reactive melting of the material or reduction of the metal from the flux.

d) capillary soldering. Gap filling with solder is due to capillary surface tension forces.

e) non-capillary soldering.The solder fills the gap under the action of an external force (external pressure, vacuum in the gap, magnetic forces) or under its own weight.

3. By heating source:

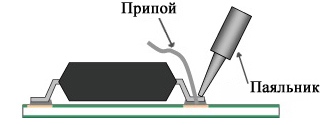

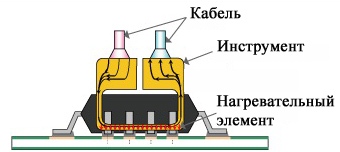

a) low-intensity methods with a heating rate of up to 150 degrees per second (with a soldering iron, heating mats, in a furnace, using electrolytes, heated matrices). Such heating methods are characterized by relatively low equipment costs, process stability and high energy consumption.

Soldering with a soldering iron

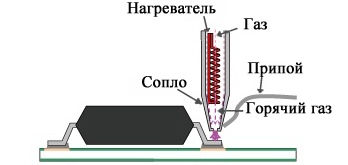

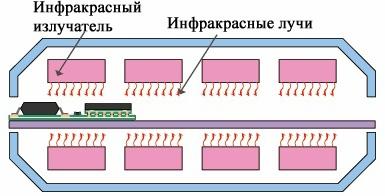

b) medium-intensity methods with a heating rate of 150 ... 1000 degrees / sec (heating by means of molten salts or solder, gas, gas flame burners, light or infrared radiation, electrical resistance, induction heating and glow discharge heating). Immersion heating is used in mass production of parts.

Hot gas (air) soldering

Infrared soldering

Resistance soldering

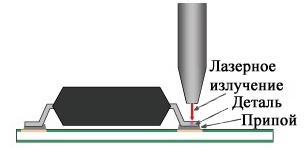

c) high-intensity methods (laser, plasma, arc, electron beam heating) with a heating rate exceeding 1000 degrees per second. These methods have the following advantages:

-

small area of thermal effect on the material;

-

the possibility of soldering thin parts with a dense arrangement of elements;

-

regulation of the process of dissolution of the base metal in the solder;

-

high performance.

One of the disadvantages of high-intensity methods is the need for careful preparation of the soldered surfaces and the high cost of the equipment.

Laser soldering

4. Also distinguish simultaneous soldering (with simultaneous formation of seams along the entire length) and stepwise soldering (gradual formation of product seams).

5.According to the temperature of the soldering process:

a) low-temperature process (less than 450 degrees),

b) high temperature (more than 450 degrees).