Explosion welding - what it is and how it is used

Very often in the process of designing structures, engineers are faced with the problem of material selection — those materials that are ideal for performing some structural functions do not have the necessary properties to meet other operational requirements. For example, a material may have good corrosion resistance, electrical conductivity, and thermal conductivity, but insufficient hardness or wear resistance. Materials produced by explosion welding.

Very often in the process of designing structures, engineers are faced with the problem of material selection — those materials that are ideal for performing some structural functions do not have the necessary properties to meet other operational requirements. For example, a material may have good corrosion resistance, electrical conductivity, and thermal conductivity, but insufficient hardness or wear resistance. Materials produced by explosion welding.

Explosive welding as a possible technological process was discovered during the Second World War, when fragments of shells welded with other metal objects were found after the explosion of bombs. In the early 1960s, DuPont developed a practical explosive welding process and patented it in the United States.

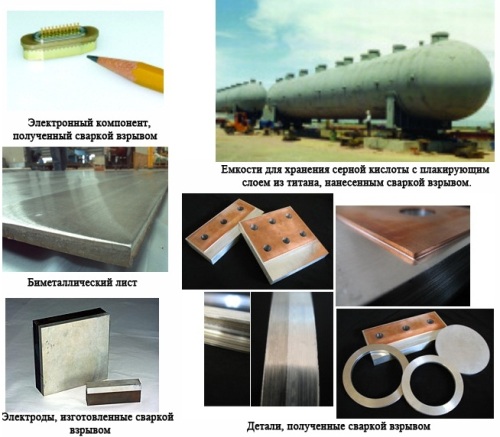

Since then, explosion welding technology has developed rapidly and is applied in many fields, from the production of bimetals for the petroleum industry to sealed joints in electronics.Parts obtained by explosion welding made it possible to reach the previously unattainable limit of product service life — up to 30 years.

The process of explosion welding is at first glance quite simple. The metals to be joined must be placed close together with a small gap. The explosive layer is evenly distributed over the top plate. The resulting sandwich structure bursts and a new structural material is formed.

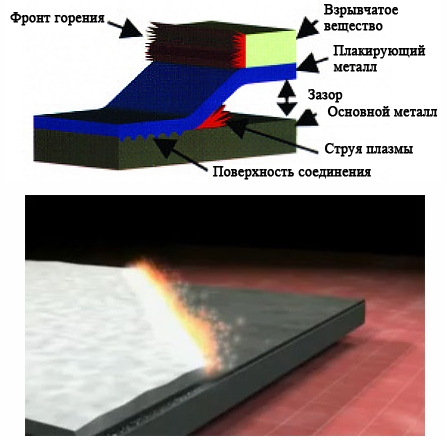

Explosion welding process

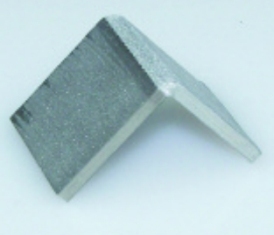

From two separate and often completely different materials, a single welded metal composition can be obtained. Bimetallic plate they can then be further processed (eg rolling) for use in various products. The thickness of the cladding layer applied to the base metal can vary from several tenths of a millimeter to several tens of centimeters.

Examples of products obtained by explosive welding

After welding, as a rule, straightening of the resulting joint is required, which is carried out on rollers or on a press. Control operations follow — mechanical tests and ultrasonic testing of the weld seam.

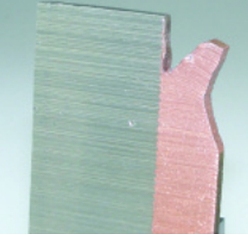

Chisel testing of the welded joint shows that the fracture does not occur along the weld.

A welded sample of stainless steel and aluminum is subjected to a bending test. The fracture occurred in the aluminum, not the weld

In reality, however, the process is much more complicated. In order to obtain a high-quality connection without delamination, careful control of a number of technological parameters is necessary, and the production of high-quality composites requires considerable experience in this matter.

The most common welding explosive is igdanite (a mixture of ammonium nitrate and hydrocarbon fuel, most often diesel).

The amount of explosives can vary widely, but most welding operations are carried out using explosives weighing 10 ... 1000 kg. Obviously, such dangerous work cannot be done in a normal production welding shop. Blast welding should be performed by licensed and experienced engineers away from the location of people. Precautions related to blasting and storage of explosives should be applied.

During the welding process, a very large force is generated in the zone of exposure to the explosive, which can reach several hundred thousand tons. The surface atomic layers of each of the materials being joined are exposed to the plasma jet. The plasma induces the formation of a metallic bond, in which the metals are separated from each other by valence electrons.

At a more macroscopic level, the welded joint appears as a wavy line along the direction of the explosion. The "amplitude" of the wave formation depends on the angle and speed of detonation. In extreme cases, it can be so large that it results in unwanted voids under the crests of the wave. The detonation angle is usually less than 30 degrees.

In this photo, the wavy nature of the bond between two metals is clearly visible.

Explosion welding has a wide range of materials that need to be joined. In some cases, the quality of the composite welded joint can be improved by placing a thin interlayer between two different layers. Sandwiches of four or more layers of metal are also not uncommon.The total number of possible combinations of bimetals, according to experts, is more than 260 options.

The use of bimetals obtained by explosion welding can significantly increase the service life and increase the reliability of thermal, foundry, petroleum equipment, heat exchangers and containers in the chemical industry. Steel-aluminum composites are used in the manufacture of electrodes.

Welded bimetallic sheets can be used as transition elements when assembling structures from different metals. Coatings for linings made of precious metals can significantly reduce the cost of parts previously made entirely of expensive materials, while not deteriorating, and sometimes even receiving much higher technical characteristics.

Explosive welded structures are used successfully in the construction of marine structures because they can significantly reduce or completely eliminate electrochemical corrosion in the marine environment. Thin layers of shielding materials applied by this welding method protect spacecraft from radiation.