Telemechanical systems in energy

Telemechanization — equipping technical objects with telemechanics for the purpose of controlling objects remotely and combining them into single complexes with centralized control. Telemechanization can be full or partial, depending on the functions performed by this system.

Telemechanics Represents a set of equipment and software that provide the ability to receive and transmit information, signals from various objects, and also allow you to control the equipment of these objects.

In this article, we will consider what the telemechanical systems of electric power facilities are - power plants, substations.

The telemechanics of power equipment is actually such an automated process control system (APCS), it includes several separate systems:

-

automatic control systems (ACS);

-

dispatch and technical means of control (SDTU);

-

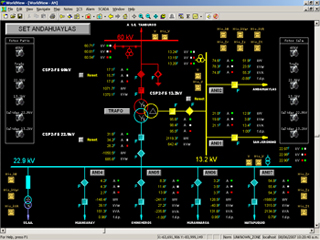

software for collecting, processing, storing, analyzing various information about the operation of electrical equipment (SCADA);

-

Automated Commercial Electricity Metering System (ASKUE);

-

dashboards, panels with switching devices, instruments.

To transfer data between telemechanical systems objects with central control points, depending on the mutual location of the objects, use wireless, cable communication, high-frequency communication over high-voltage power lines.

To transfer data between telemechanical systems objects with central control points, depending on the mutual location of the objects, use wireless, cable communication, high-frequency communication over high-voltage power lines.

Telemechanics systems are built in such a way as to guarantee high accuracy, speed and reliability in the transmission of information, equipment control signals. Also, one of the main tasks of these systems is to organize fast and accurate recording of changes in certain parameters of the electrical network, the state of the equipment, which is ensured due to the maximum automation of this process.

Telemechanics systems are used to organize monitoring and control over equipment at sites located at varying degrees of distance from the control center. In energy facilities, where it is forbidden to stay for a long time or it is completely impossible for a person to stay (for example, due to high background radiation, high level of pollution).

Advantages and disadvantages of telemechanical systems in the power industry

Advantages of telemechanical systems include:

— independence from the remoteness of objects for control and management of energy facilities (for electric distribution substations — the central dispatch center).Due to the presence of telemechanical systems in power facilities and the use of modern communication facilities, the control and management of these facilities can be carried out from any point, regardless of the relative location of the facilities. That is, through telemechanical systems it is possible to organize control and management of objects located, for example, in several areas;

— possibility to control the operative-technical staff. During the operational start-up of the equipment, especially during the elimination of accidents and technological violations, operational-technical personnel may make a mistake. Due to the availability of APCS systems, in particular SCADA, a duty dispatcher who issues commands for equipment operations in a substation, can monitor the execution process of commands in real time.

If mistakes are made during work performing an operational switchover, the dispatcher on duty can promptly detect this error and inform the service personnel about it, which allows to prevent the occurrence of various negative consequences.

For example, if it is necessary to remove a power transformer for repair, the operating personnel will perform all necessary operations to disconnect this item of equipment from the electrical network, but will ground this item only after the higher operating personnel - the dispatcher on duty personally make sure that the performed switches and production are possible further operations — grounding of the power transformer. Depending on the complexity of the switches being performed, this check may be performed several times;

— cost reduction.Thanks to the presence of telemechanical systems in power equipment, it is possible to significantly reduce the maintenance costs of maintenance personnel, since the control over the operation mode of the equipment, reading information from microprocessor terminals for the protection of the equipment about violations of the operation modes in electrical networks, as well as carrying out operations with high-voltage switches, circuit breakers with motor drives, it is possible to carry out remotely;

— efficiency. The management of equipment by personnel directly in the facility takes a certain amount of time: detect a malfunction, record a log, report to higher-level personnel, receive a command to execute certain commands, record a command in a log, execute a command, record complete journal command reporting to higher-ranking personnel.

In the case of remote control of the equipment through APCS systems, the necessary operations are carried out faster, since the command can be executed directly by the dispatcher on duty immediately when such a need arises.

As far as disadvantages go, the most obvious disadvantage of telemechanical systems is their vulnerability. The telemechanical system is a complex set of equipment, one of the elements of which can fail at any time. This will lead to incorrect operation of this system, the presence of false signals or its complete inoperability. Such work disruptions are rare enough, but they do happen.

Based on the above, it can be concluded that it is impossible to completely abandon service personnel in power plants equipped with telemechanical systems, since in the event of a telemechanical system failure or errors in its operation, personnel intervention is required.

However, the use of these systems in the power industry can significantly reduce the number of service personnel. For example, in a group of several substations, due to the availability of telemechanical systems, there is no need for permanent maintenance staff at each of the substations, since control over all objects is carried out remotely from the control room.

In this case, only an on-site team is sufficient to service the facilities, which will arrive at the facility in case of emergencies requiring operational intervention by staff. In the absence of telemechanical systems in the substations, for constant control over the operation of the equipment and for the purpose of timely detection of malfunctions and emergency situations, it is necessary to have permanent maintenance personnel in the substations.

See also: Remote control in electrical networks