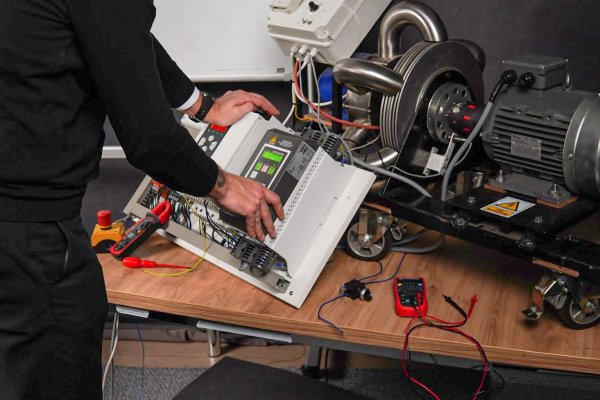

How to choose a soft starter for an electric motor

Electric motor soft starters allow not only to reduce starting current at startup time. They are also able to provide overload control, thereby extending the life of the equipment and controlling its shutdown as quickly as possible, which is also important.

First of all, when choosing a soft starter, you should pay attention to the maximum current of the electric motor at the highest load, the maximum number of starts per hour and the value of the supply voltage.

Roughly, the operating modes of soft starters, according to the starting current value, can be divided into the following three:

-

Light. The starting current does not exceed three times the rated value, and the starting time does not exceed 20 seconds. In light mode you can start: screw and centrifugal compressors, centrifugal fans, pumps, conveyor drives, various drills and lathes.

-

Heavy. The inrush current reaches 4.5 nominal values. This applies to devices with a significant moment of inertia, the start of which lasts up to 30 seconds.These are compressors under load, impact crushers, vertical conveyors, winches, sawmills, presses, cement pumps, etc.

-

Especially heavy. In this mode, the starting current can be more than 6 times the rated value, while the acceleration can take a very long time. These include: screw crushers, piston pumps, various centrifuges, ball mills, band saws, high pressure blowers under load, liquid separators, etc.

Next, we will consider all types of characteristics of soft starters, their functions, the presence or absence of which should be paid attention to when choosing a specific model to solve a specific, previously known problem.

An important feature of the soft starter is its ability to control current. In simple devices the voltage is gradually increased until its rated value is reached and this is usually sufficient for mild starting conditions. In some cases, however, it is important to limit the power directly, which is especially important when using low-power generators or weak lines, where there is a risk of an accident even from a short-term exceedance of the critical power.

The next selection criterion can be called a bypass function, that is, disconnecting the starting unit from the power circuit by activating the contactor, so that at the end of the starting stage, the operating current does not flow through the device, but directly to the load, so as not to overheat the triacs of the boot device. This applies to powerful loads. Sometimes the contactor function is built in, sometimes an external contactor is required that is triggered by a signal applied to it.

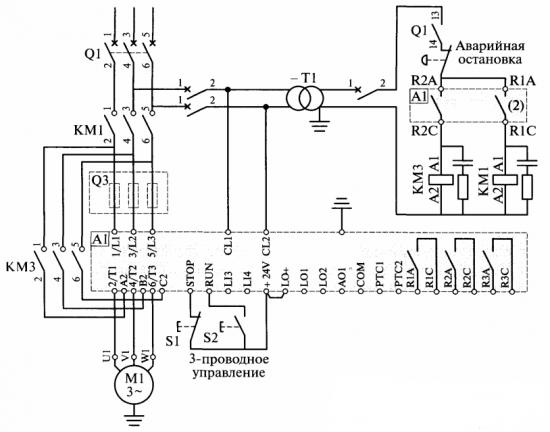

A typical connection diagram of a soft starter for one direction of rotation with mains and bypass contactors is shown in Fig. uncovered... The device is based on a thyristor voltage regulator.

Connection diagram of the soft starter for one direction of rotation of the motor

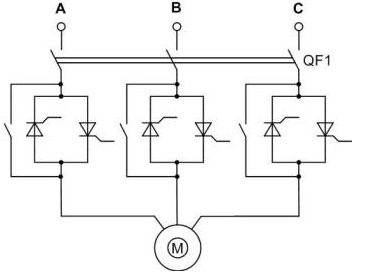

According to the number of control phases, soft starters are three-phase and two-phase. Two-phase ones are smaller and cheaper, they are suitable for light loads. However, for frequent starting, it is better and more reliable to use three-phase ones directly, which ensure full symmetry of the operating modes of all three phases.

According to the control method, the launchers are divided into analog and digital.

Digital ones have more flexible control and easily provide many additional protection functions, while analog ones are limited in functionality, controlled by potentiometers, and external control systems require the connection of additional nodes.

Electronic overload protection is an essential component of any soft starter. In addition, restart time protection, phase unbalance protection, phase reversal, undercurrent, underfrequency protection, etc. can be enabled. Some models offer a thermistor built into the motor winding. It is important not to be overlooked typing machines to protect the device in the event of a short circuit.

There are models with the ability to start the engine at a reduced speed due to pseudo-frequency control, when several reduced speeds are preset in the device and cannot be adjusted. Operation in these modes is limited in time and the function is only for debugging the equipment before starting work.

Many models have a braking function when a DC voltage is applied to the motor winding (dynamic braking). This is necessary for active load systems, such as inclined conveyors or hoists, where in the absence of a brake the system will continue to move, which is often not desirable.

For some mechanisms a jog start is useful, this is a function of short-term supply with full mains voltage to push the mechanism out of place so that further smooth acceleration can take place. This additional feature is found on some soft starters.

For pumping and ventilation equipment the function of lowering the supply voltage at low load can be useful and it will not harm the normal operation of the mechanism.

Thus, the approach to selecting a soft starter can be based on comparing specific requirements with the criteria presented above. Often, suppliers provide a program for choosing a device according to approximate calculation algorithms, which also facilitates the choice. However, the main indicators are: number of starts per hour, starting time, rated current, required current limit, stop duration, bypass, temperature and other working environment conditions.