Inverter generator - how it works and how it works

Energy surplus issues are still popular among energy consumers. For these purposes, manufacturers now mass produce electric generators of various types and capacities. Among all the designs of such devices, a special place is given to elite models that work on the principle of generating high-quality electricity.

For this purpose, their algorithm implements the method of inverter conversion of the main parameters of electrical signals. Therefore, they are called inverter generators.

They can be produced with different powers, but the most popular among the population are models from 800 to 3000 watts.

The source of energy to power the motor can be:

-

gasoline:

-

diesel fuel;

-

natural gas.

How an inverter generator works

The design of the device enclosed in a single body includes:

-

an internal combustion engine,

-

alternator:

-

inverter converter block;

-

connectors for connecting output circuits;

-

control and monitoring bodies for tracking technological processes.

To connect electrical appliances, common industrial power generation is used through three power contacts of a common standard socket AC 220 volts.

In addition to alternating current voltage, the alternator provides direct current that can be used for charging. different batteriesfor example, used to start a car engine. For this purpose, the delivery kit includes special clamps for connecting it to its input terminals.

The generator is equipped with protections that automatically open the supply circuit when an excessive load is connected to the output contacts. Also, protections control the technical condition of the engine, especially the achievement of a critical oil level. When there is insufficient lubrication of all moving parts, the motor will automatically stop due to the action of protections. To avoid this, it is necessary to monitor the oil level in the crankcase.

These generators are usually equipped with a four-stroke engine with overhead valves.

The principle of operation of the inverter unit

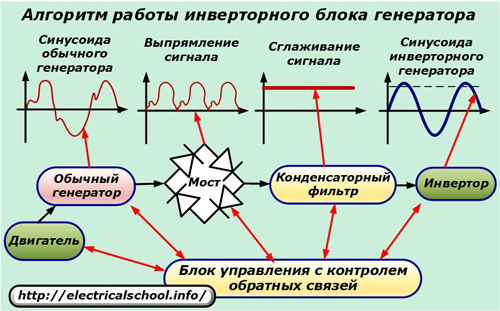

The diagram of the interconnection of various technological processes taking place during the inversion of signals is illustrated by the figure.

An internal combustion engine turns a conventional generator that generates electrical energy sinusoidal… Its flow is directed to the rectifier bridge, consisting of power diodes located on powerful cooling radiators. As a result, a ripple voltage is obtained at the output.

After the bridge there is a capacitor filter that smoothes the ripples to a stable straight line typical of DC circuits.Electrolytic capacitors are specially designed for reliable operation with voltages above 400 volts.

The reserve is made to exclude the influence of pulsating peaks on the amplitude of the operating voltage 220 V: 220 ∙ 1.4 = 310 V. The capacity of the capacitors is calculated according to the power of the connected load. In practice, it varies from 470 μF and more for one capacitor.

The inverter receives a rectified stabilized direct current and generates a high-quality harmonic from it industrial frequency.

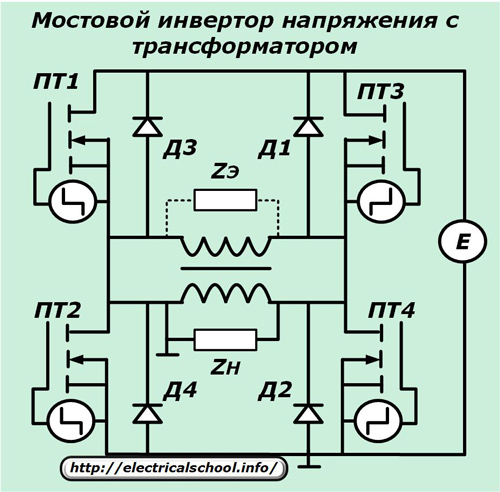

Different algorithms of technological processes have been developed for the operation of the inverter, but bridge circuits with a transformer have the best signal shape.

The main element that forms the sinusoidal signal is a semiconductor transistor switch assembled IGBT elements or MOSFIT.

To form a sinusoid, the principle of creating a repeatedly repeating periodicity is used pulse width modulation… To implement, each half-period of the voltage swing is formed by firing a certain pair of transistors in a high-frequency pulse mode with a corresponding amplitude that changes over time according to the sine law.

Final alignment of the sine wave and smoothing of pulse peaks is performed by a high-pass low-pass filter.

Therefore, the Inverter block is used to convert the electricity generated by the generator windings into a stabilized value with accurate metrological characteristics that provide a steady frequency of 50 Hz and a voltage of 220 volts.

The operation of the inverter unit is carried out by a control system, which through feedback controls all technological processes of the generator from various states of the internal combustion engine to the shape of the voltage sine wave and the magnitude of the load connected to the output circuits.

In this case, the current coming from the generator windings to the converter block can significantly differ in frequency and waveform from the nominal values. This is the main difference between inverter models from all other designs.

The use of inverters provides significant advantages over conventional generators:

1. They have increased efficiency due to the automatic adjustment of the engine speed during operation and the creation of an optimal mode for it according to the actual load value.

The more power is applied to the engine, the faster its shaft begins to rotate under conditions where fuel consumption is strictly balanced by the control system. In traditional generators, fuel consumption is weakly dependent on the applied load.

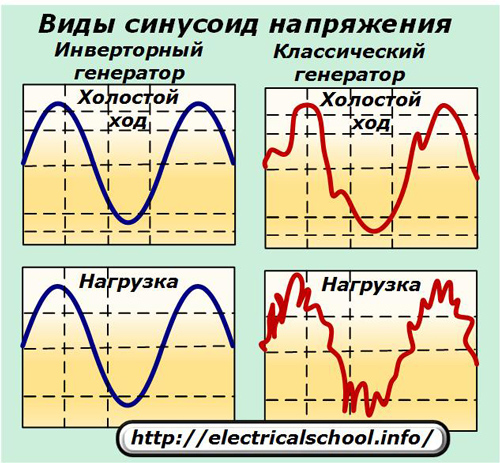

2. Inverter generators give an almost perfect sine wave when feeding consumers under load. This high-quality current is very important for the operation of sensitive digital equipment.

3. The dimensions of elite models are compact and light compared to conventional devices with the same power.

4. Reliability inverter generators are so high that their manufacturers guarantee twice the life of their simple counterparts.

Inverter generators are designed for use in three modes:

1.continuous operation at a nominal load that does not exceed the output power declared by the manufacturer;

2. short-term overload of no more than half an hour;

3. starting the engine and reaching the operating mode of the generator, when it is necessary to overcome large opposing forces of the rotation of the rotor and the capacitive load in the circuit of the power section.

In the third mode, the inverter can handle a significant amount of reverse instantaneous power, but its operating time is limited to only a few milliseconds.

How to start the engine

To do this, you need to perform a number of operations. Let's look at their sequence on the example of one of the available models of the generator ER 2000 i. Action priority:

1. check the oil level, because without it the start will not happen due to blocking by protections and a very high probability of failure;

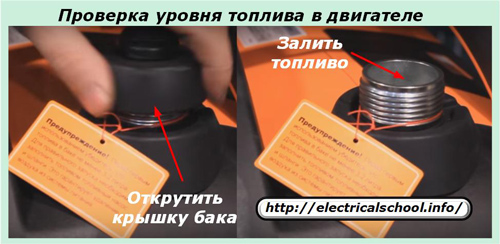

2. pour fuel — without it, the engine will have nowhere to get energy to create a rotary motion;

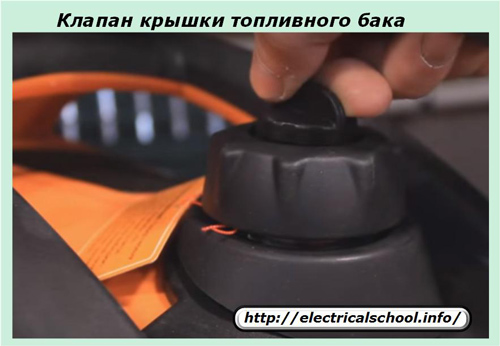

3. open the fuel tank cap valve;

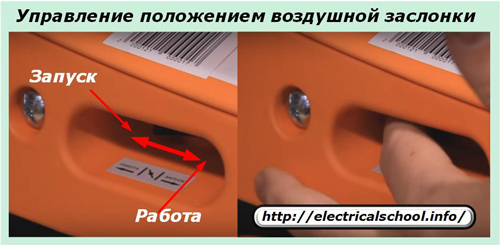

4. switch the throttle to the «Start» position;

5. put the handle of the fuel tap in the «Operation» position;

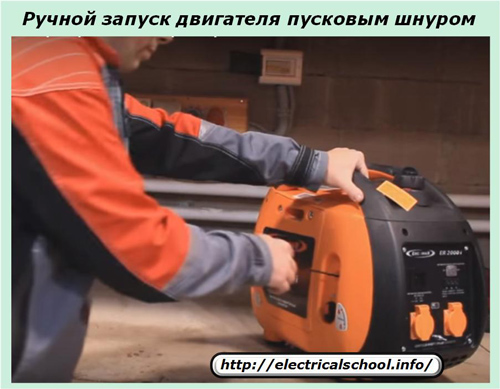

6. start the generator by hand cranking the cable.

When the engine is initially started, the overload light comes on for a short time, and then for a long time - a voltage indicator in normal mode, the burning of which indicates optimal operating conditions.

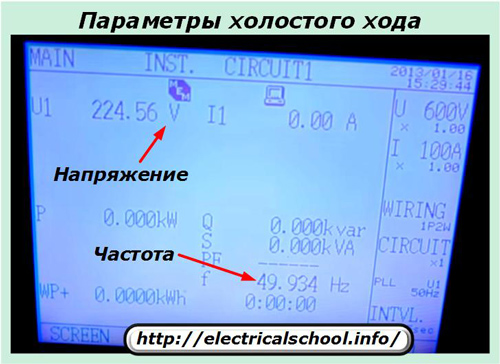

After starting the engine, the generator idles and has optimal electrical parameters. The voltage and frequency shown in the picture are normal values.

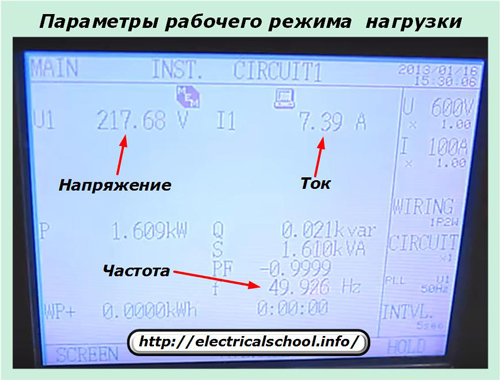

After checking the idle characteristics, we connect the load to the generator, for example, using a powerful industrial hair dryer.

The power of the connected device did not change the voltage and frequency of the output of the device, and from the indication of the operating current, the power consumed by the hair dryer can be estimated.

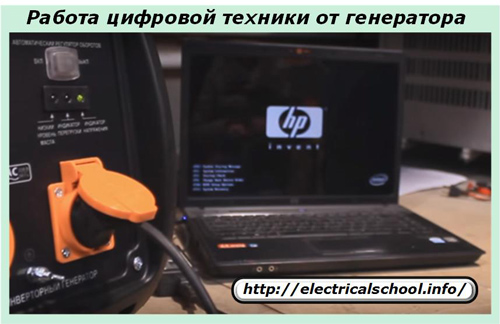

After this experiment, we connect digital computers to the DC output and see that it works reliably. When using conventional generators without an inverter unit, digital microprocessor devices fail due to the poor quality of the supply voltage.

Recommendations for safe use

Inverter generators are equipment that use microprocessor devices and a sophisticated electronic database. Correct observance of operating conditions, as well as careful transportation and maintenance of temperature and humidity conditions during storage are a guarantee of its long-term operation.

If you are constantly in an unheated garage during the winter, condensation can form on all internal parts, which will cause damage to electronic components.