Transformer OSM — purpose, device, characteristics

Originally, the OSM series transformers included single-phase, dry-type, multi-purpose transformers, with ratings typically in the range of 63 VA to 4 kVA. The primary voltage for this series of transformers is in the range of 220 V to 660 V, and the typical voltage range of the secondary windings is 5 V to 260 V.

These transformers are very popular and are used for various purposes, including their main purpose: powering local lighting circuits, control circuits, alarm systems, automation, etc.

Since the days of the indestructible USSR, transformers such as OSM have been widely used, and they began to be produced in the Soviet Union from 1928 at the Moscow Transformer Plant, which was later renamed Electrozavod, and where OSM transformers with a capacity of up to 4 kVA are still produce.

Single-phase transformers of this series invariably comply with GOST 19294-84 and climatic conditions-GOST 15150-69 and do not exceed the conditions for T3, UHL3, U3, that is, within the limit for UHL3, an operating temperature of up to — 70 ºС is permissible.These transformers are resistant to shock loads at acceleration up to 8G, as well as vibration at frequencies from 10 to 60 Hz and at acceleration up to 2G.

Installation of transformers is allowed in closed rooms with a non-explosive, non-aggressive environment, at a height of up to 1000 m above sea level and at an average ambient temperature of -45 ºС to +40 ºС.

So, OSM transformers are universal built-in transformers.

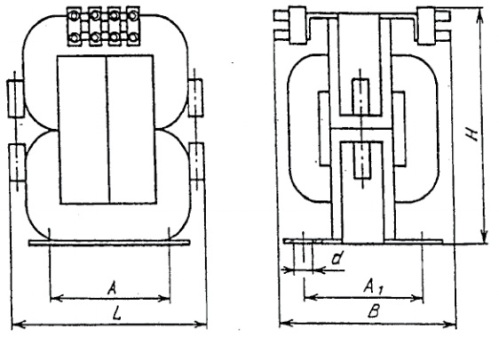

OSM transformers with a capacity of 1.6 kVA, 2.5 kVA and 4 kVA are designed for installation on a horizontal surface. As for small transformers, with a capacity of up to 1 kVA, they can be installed on both horizontal and vertical surfaces, depending on the needs of the user.

For OSM transformers with a capacity of up to 2.5 kVA in climatic versions U and UHL, as well as for version T, as well as for all versions of transformers with a capacity of 4 kVA, the insulation class in terms of resistance to heating corresponds to GOST 8865-93 .

If the transformers, almost identical in parameters, are different in climatic design, that is, the electrical indicators are similar, then the difference lies only in the protective coating. Protection against electric shock is due to class I in accordance with GOST 12.2.007.0-75 and degree of protection IP00 in accordance with GOST 14254-96. In principle, it is possible to agree between the customer and the transformer manufacturer on an improved degree of protection of the terminals and terminals, for example up to class IP20.

Typical OSM transformers have a twisted split core made of electro-laminated cold-rolled steel as a magnetic circuit. The coils have a frame construction made of copper wire in heat-resistant insulation.At the end of production, the coils are impregnated with electrically insulating moisture-resistant varnish, necessarily under vacuum conditions, in order to eliminate inhomogeneities in the impregnation.

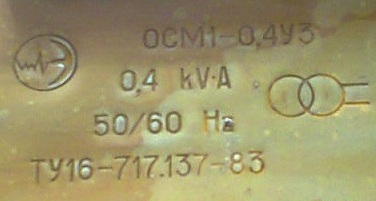

On the top of the transformer is indicated its type, year of manufacture and a short-circuit instability symbol is also applied. On the terminal blocks, just above the terminals, the nominal voltage of its windings is indicated. The symbol «U» indicates the beginning of the primary winding, and the symbol «O» - the beginning of the secondary windings.

The marking of the OSM transformer is quite simple. For example, if a transformer fell into your hands, on which it is written: «OSM1-0.4 UZ 220 / 36-5». This means that this transformer has a nominal power of 400 watts, it is intended for operation in areas with a moderate microclimate, in covered rooms without special regulation of temperature conditions with natural ventilation (that is, the temperature practically does not differ from the outside temperature, there are no drafts water and splashes, and the amount of dust in the ambient air is negligible).

The maximum operating temperatures of the transformer are from -50 ºС to +45 ºС, and the maximum external humidity is 98% at 25 ºС. The primary winding is designed for 220 V, the secondary for 36 V, there is a 5 V tap.

The winding connections for different models of OSM transformers are different and the windings can be split or tapped. The figure below schematically shows the main options for their implementation.

Technical characteristics of OSM transformers

When the OCM transformer is finally installed in any installation, machine or machine, then it is necessary to take into account the provision of protection against water ingress, protection against accidental touches, overload protection, which allows the device itself to be implemented in which the transformer is installed. In this case, the terminals of the terminals allow the connection of aluminum or copper wires with a cross section of up to 2.5 mm and no more than two wires for each terminal.

In addition, if the presence of alkaline and acid vapors in the ambient air is possible in the room, then it is not recommended to install the OSM transformer in such a room, as this will have a detrimental effect on the materials of the transformer: corrosion will appear, the insulation of the windings it will get worse. Operation and installation, however, are in any case carried out taking into account the PTE of the electrical installations of consumers and PTB during their operation. »

When the transformer is used to supply local lighting circuits, one terminal of the secondary winding, as well as the transformer body, must be reliably earthed with a wire with a cross section of 2.5 mm, if an aluminum wire is used, and of 1.5 mm if copper wire is used for grounding. It should be taken into account that the insulation conductivity of the OCM transformer should not be significant, its resistance is lower than 500 kOhm, due to safety and efficiency requirements, it is unacceptable.

In terms of transformer applications in general, many variations are possible.Initially, OSM transformers are applicable as universal step-down transformers, but there are also specialized models designed, for example, to power specific machine-metalworking equipment, for use in laboratories, to power various special drives.

Someone is cooking in the country, using a sufficiently powerful OSM transformer as a reliable source of welding current for arc welding, someone is designing machines for spot welding. Power supplies for amplifiers and other household appliances are developed based on OSM transformers.

The production of OSM transformers to order is also not something exceptional today. Possible production toroidal transformers OSM, power up to 25 kVA and more, on request, with the required output current parameters. OSM toroidal transformers are gaining more and more popularity; they will be more compact and economical.

OSM transformers are stored in closed rooms, with a relative humidity of no more than 80% and are subject to good natural ventilation. As stated above, alkaline and acid vapors must also be excluded. Sudden fluctuations in humidity and temperature, which can lead to the formation of dew, which can damage the transformer and deteriorate its characteristics, are also unacceptable.

When transporting OSM transformers, it is important to exclude the effects of atmospheric precipitation and mechanical influences that can physically damage the transformer. The transformer packs are securely fastened in the vehicle in a suitable manner suitable for the vehicle in use.

The warranty period of the OSM transformer is at least 3 years from the moment of using the transformer as intended.