Electric pressure sensors

Today, in order to measure pressure in various areas of industry, not only mercury barometers and aneroids are used, but also various sensors that differ both in the principle of operation and in the advantages and disadvantages inherent in each type of such sensors. Modern electronics allow the implementation of pressure sensors directly on an electrical, electronic basis.

So what do we mean by the term "electrical pressure sensor"? What are electrical pressure sensors? How are they arranged and what functions do they have? Finally, which pressure sensor should you choose so that it is most suitable for a particular purpose? We will find out in the course of this article.

First, let's define the term itself. A pressure sensor is a device whose output parameters depend on the measured pressure. The test medium can be a vapor, a liquid, or some gas, depending on the application of a particular sensor.

Modern systems require precision tools of this type as important components of automation systems for power, oil, gas, food and many other industries.Miniature pressure transducers are vital in medicine.

Each electrical pressure sensor includes: a sensitive element that serves to transmit the shock to the primary transducer, a signal processing circuit and a housing. Mainly electrical pressure sensors are divided into:

-

Resistive (tensoresistive);

-

Piezoelectric;

-

Piezo resonance;

-

Capacitive;

-

Inductive (magnetic);

-

Optoelectronic.

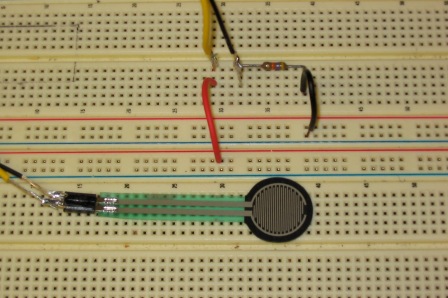

Resistive or strain gauge pressure sensor This is a device whose sensitive element changes its electrical resistance under the action of a deforming load. Strain gauges are mounted on a sensitive membrane that bends under pressure and bends the strain gauges attached to it. The resistance of the strain gauges changes and the magnitude of the current in the primary circuit of the converter changes accordingly.

Stretching the conductive elements of each strain gauge causes an increase in length and a decrease in cross-section, resulting in an increase in resistance. In compression it is the opposite. Relative changes in resistance are measured in thousandths, so precision amplifiers with ADCs are used in signal processing circuits. Thus, the strain is converted into a change in the electrical resistance of a semiconductor or conductor and then into a voltage signal.

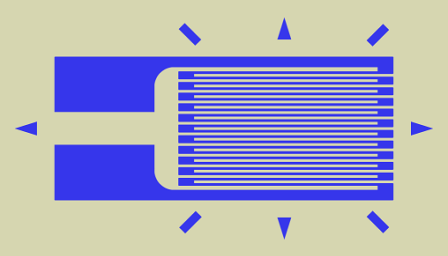

Strain gauges are usually a zigzag conductive or semiconductor element applied to a flexible base that adheres to the membrane. The substrate is usually made of mica, paper, or polymer film, and the conductive element is a foil, thin wire, or semiconductor vacuum-sprayed onto metal.The connection of the sensitive element of the strain gauge to the measuring circuit is carried out using contact pads or wires. The strain gauges themselves usually have an area of 2 to 10 sq. mm.

Load cell sensors great for estimating pressure levels, compressive strength and weight measurement.

The next type of electric pressure sensor is piezoelectric… Here, the piezoelectric element acts as a sensitive element. A piezoelectric element based on a piezoelectric generates an electrical signal when it is deformed, this is the so-called direct piezoelectric effect. The piezoelectric element is placed in the measured medium and then the current in the transducer circuit will be proportional in magnitude to the pressure change in that medium.

Since the appearance of the piezoelectric effect requires a precise change in pressure rather than a constant pressure, this type of pressure transducer is only suitable for dynamic pressure measurement. If the pressure is constant, then the deformation process of the piezoelectric element will not occur and the current will not be generated by the piezoelectric.

Piezoelectric pressure sensors are used, for example, in primary flow transducers of vortex meters for water, steam, gas and other homogeneous media. Such sensors are installed in pairs in a pipeline with a nominal opening of tens to hundreds of millimeters behind the body of the flow and thus register vortices whose frequency and number are proportional to the volumetric flow rate and the flow rate.

Consider further piezo-resonant pressure sensors... In piezo-resonant pressure sensors, the reverse piezoelectric effect works, in which the piezoelectric is deformed under the action of the applied voltage, and the higher the voltage, the stronger the deformation. The sensor is based on a resonator in the form of a piezoelectric plate, on both sides of which electrodes are applied.

When an alternating voltage is applied to the electrodes, the plate material vibrates, bending in one direction or another, and the frequency of the vibrations is equal to the frequency of the applied voltage. However, if the plate is now deformed by applying an external force to it, for example through a pressure-sensitive membrane, then the frequency of the free oscillations of the resonator will change.

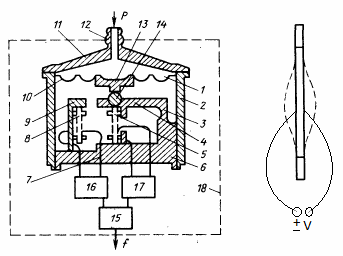

So, the natural frequency of the resonator will reflect the amount of pressure on the membrane that presses on the resonator, resulting in a change in frequency. As an example, consider an absolute pressure sensor based on piezo resonance.

The measured pressure is transmitted to chamber 1 through connection 12. Chamber 1 is separated by a membrane from the sensitive measuring part of the device. Body 2, base 6 and membrane 10 are sealed together to form a second sealed chamber. In the second sealed chamber of the base 6, holders 9 and 4 are fixed, the second of which is attached to the base 6 by means of a bridge 3. The holder 4 serves to fix the sensitive resonator 5. The supporting resonator 8 is fixed by the holder 9.

Under the action of the measured pressure, the membrane 10 presses through the sleeve 13 on the ball 14, which is also fixed in the holder 4.The ball 14, in turn, presses the sensitive resonator 5. Wires 7, fixed in the base 6, connect the resonators 8 and 5 to the generators 16 and 17, respectively. To generate a signal proportional to the magnitude of the absolute pressure, circuit 15 is used, which generates an output signal from the difference in the frequencies of the resonator. The sensor itself is placed in an active thermostat 18, which maintains a constant temperature of 40 ° C.

Some of the simplest are capacitive pressure sensors... The two flat electrodes and the gap between them form a capacitor. One of the electrodes is a membrane on which the measured pressure acts, which leads to a change in the thickness of the gap between the actually capacitor plates. It is well known that the capacitance of a flat capacitor changes with a change in the size of the gap for a constant area of the plates, therefore, to detect even very small changes in pressure, capacitive sensors are very, very effective.

Capacitive pressure sensors with small dimensions allow measurement of overpressure in liquids, gases, steam. Capacitive pressure sensors are useful in various industrial processes using hydraulic and pneumatic systems, in compressors, in pumps, on machine tools. The design of the sensor is resistant to temperature extremes and vibrations, immune to electromagnetic interference and aggressive environmental conditions.

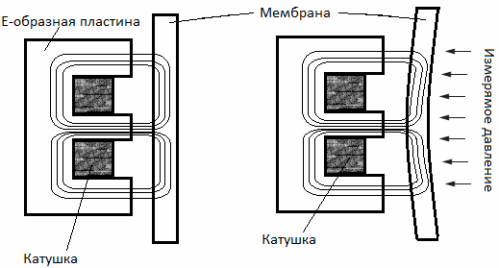

Another type of electrical pressure sensors, remotely similar to capacitive - inductive or magnetic sensors... The pressure-sensitive conductive membrane is located at some distance from the thin W-shaped magnetic circuit, on the middle core of which the coil is wound.A certain air gap is set between the membrane and the magnetic circuit.

When a voltage is applied to the coil, the current in it creates a magnetic flux that passes both through the magnetic circuit itself and through the air gap and through the membrane, closing. Since the magnetic permeability in the gap is approximately 1000 times smaller than in the magnetic circuit and in the membrane, even a small change in the thickness of the gap leads to a noticeable change in the inductance of the circuit.

Under the influence of the measured pressure, the sensor diaphragm bends and the complex resistance of the coil changes. The transducer converts this change into an electrical signal. The measuring part of the converter is made according to the bridge circuit, where the coil of the sensor is included in one of the arms. Using an ADC, the signal from the measuring part is converted into an electrical signal proportional to the measured pressure.

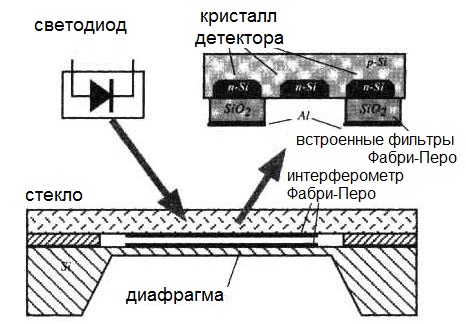

The last type of pressure sensor we will look at is optoelectronic sensors… They are quite simple to detect pressure, have high resolution, have high sensitivity and are thermally stable. Operating on the basis of light interference, using a Fabry-Perot interferometer to measure small displacements, these sensors are particularly promising. An optical converter crystal with an aperture, an LED and a detector consisting of three photodiodes are the main parts of such a sensor.

Fabi-Perot optical filters with a small thickness difference are attached to two photodiodes. These filters are reflective silicon mirrors from the front surface covered with a layer of silicon oxide, on the surface of which a thin layer of aluminum is deposited.

The optical transducer is similar to a capacitive pressure sensor, the diaphragm formed by etching in a monocrystalline silicon substrate is covered with a thin layer of metal. The underside of the glass plate also has a metal coating. There is a gap of width w between the glass plate and the silicon substrate, obtained using two spacers.

Two layers of metal form a Fabia-Perot interferometer with a variable air gap w, which includes: a movable mirror located on the membrane, which changes its position when the pressure changes, and a stationary translucent mirror parallel to it on a glass plate.

On this basis, FISO Technologies produces microscopic sensitive pressure transducers with a diameter of only 0.55 mm that easily pass through the eye of the needle. With the help of a catheter, a mini-sensor is inserted into the studied volume, inside which the pressure is measured.

The optical fiber is connected to an intelligent sensor, in which, under the control of a microprocessor, a source of monochromatic light introduced into the fiber is turned on, the intensity of the back-reflected light flux is measured, the external pressure on the sensor is calculated from the calibration data and displayed on the display . In medicine, for example, such sensors are used to monitor intracranial pressure, to measure blood pressure in the pulmonary arteries, which cannot be reached in any other way.