Conductometric level sensors - design and principle of operation

A standard task, very common in industry, in particular in the food industry, is to signal when a certain level of liquid in a container has been reached. There are many methods to solve this problem, but the simplest and cheapest way is to use conductometric level sensors.

Such sensors can successfully work with electrically conductive liquids with a conductivity of 0.2 S / m or more. Such liquids include potable and industrial water, weak solutions of bases, acids, waste water and food liquids (e.g. yeast or beer).

The principle of operation of conductometric sensors is based on the fact that when the liquid in the container reaches a certain level, the working liquid closes the sensor electrode to the body of the metal tank or to the additional electrode of the sensor itself, causing an electric current in the sensor circuit. As a result, closing the sensor circuit causes the relay to activate, which in turn controls the corresponding circuit.

According to temperature and pressure conditions, conductometric level sensors are basically capable of working at temperatures up to + 350 ° C and at pressures up to 6.3 MPa, which is determined by the material of the electrode insulator, and the manufacturer indicates specific values in the accompanying documentation.

Obstacles to the normal operation of the conductometric sensor can be: strong foaming of the liquid, strong evaporation of the working medium, formation of insulating deposits on the sensitive element of the sensor and conductive deposits on its insulator. The manufacturer tries to prevent all these obstacles by choosing a more suitable material for the sensor.

Let's look at the physics of the work flow of a conductometric sensor, that is, we will slightly touch the essence of conductometry. The electrical resistance of the solution, respectively — its electrical conductivity, characterize the ability of a given solution to conduct electric current to a certain extent.

These parameters are strongly related to the physico-chemical properties of the solute and the solvent: the concentration of dissolved ions and their mobility, the charge of these ions, the temperature of the solution, the pressure and many other factors.

Electrical conductivity is measured in Siemens per centimeter (S/cm). The characteristic of ultrapure and pure waters is the resistance expressed in ohms per centimeter (ohm * cm).

According to the terminology of conductometry, a conductometric cell is a sensitive element of a sensor, it is characterized by a cell constant.

In the classic form, the conductometric cell consists of two parallel electrodes with an area of several square centimeters, which are immersed in a solution, and the distance between them is usually several centimeters.

For each such installed sensor, the cell constant (s) can be entered and expressed in 1/cm. Today, more and more conductometric sensors have stainless steel electrodes, while the constants are different.

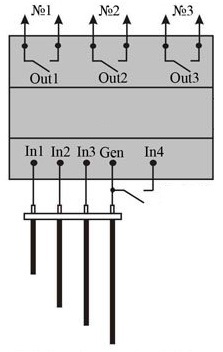

Conductivity level sensors can monitor one or more specified levels of a conductive fluid. And the principle is always the same — the electrical conductivity of the liquid differs from the electrical conductivity of the air, which the electrodes fix. Sensors can be single-electrode or multi-electrode, which allows you to track multiple liquid levels.

In its simplest form, a conductometric level sensor is made of stainless steel electrodes, one of which serves as a common in the control circuit and is installed in the container so that its working part is in constant contact with the liquid, in particular, the conductive body of the container with the liquid can become the common electrode ... Other electrodes will be signal and are located at certain levels to be monitored.

In the process of filling the container with liquid, the signal electrodes are successively in contact with this liquid, and the circuits are closed one after the other. Accordingly, the device's signal outputs are triggered.

Single electrode sensors are suitable for use in closed or open metal containers. Sensor bushings can be PTFE, ceramic or plastic. The rods are made of stainless steel.In the manufacture of sensors, special attention is paid to their structure, which must prevent false alarms due to liquid accumulation.

Five-electrode, four-electrode and three-electrode conductometric level sensors are used to monitor, as noted above, several liquid levels in a container, even if the walls of the container are not conductive, that is, made of an insulating material such as plastic.