How does a reversible starter differ from a conventional starter?

A magnetic starter is a low-voltage combined electromechanical device designed to start three-phase (usually) electric motors, to ensure their continuous operation, to safely disconnect the power supply, and sometimes to protect the motor circuits and other connected circuits. Some starters have the function of reversing the engine, but first things first.

In fact, magnetic switch — this is an improved, modified contactor, it is more compact than a conventional contactor, lighter and designed specifically to work with motors, that is, the starter has a narrower direct purpose than the contactor. Some models of magnetic starters are optionally equipped with a thermal shutdown relay and phase failure protection.

To control the starting of the engine, by closing the contact groups of the starter, there is a button or a low current contact with a coil for a certain (12, 24, 36 or 380 volts) voltage, and sometimes both.

In the magnetic starter, the coil on the steel core is responsible for switching the power contact groups to which the armature is attracted, pressing on the contact group and thus closing the supply circuit. When the coil is de-energized, the return spring moves the armature to the opposite position — the supply circuit opens. Each contact is located in the arc chute.

Reversible and irreversible magnetic starters

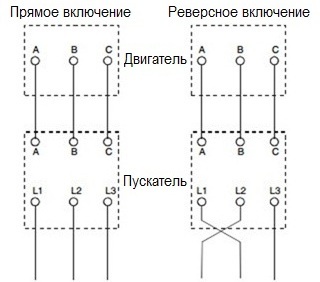

Basically, magnetic starters are of two types: irreversible and reversible. In a reversing starter, in one case, there are two separate magnetic starters that are electrically interconnected and fixed on a common base, but at the operator's option, only one of these two starters can work - either only the first or only the second.

The reversing starter is switched on by means of normally closed blocking contacts, the function of which is to exclude the simultaneous activation of two sets of contacts — reversible and irreversible, so that no phase-to-phase short circuit occurs. Some reverse models are mechanically protected to provide the same function. And since the contactors are only started in series, the supply phases can also be switched in series, so that the main function of the reversing starter is performed - changing the direction of rotation of the electric motor. The sequence of phases has changed — the direction of rotation of the rotor has also changed.

Capabilities of magnetic starters

In general, magnetic starters are capable of a lot.So, to limit the inrush current of a three-phase electric motor, its windings can first be switched from «star», then when the motor reaches the rated speed, switch to «delta». At the same time, the starters can be opened in the case of irreversible and reversible, with overload protection and without overload protection.

Each magnetic starter has both power and lock contacts. Power switches directly switch the power load circuit, while interlocks are needed to control the operation of the power contacts. Power and blocking contacts are normally open or normally closed. In the schematic diagrams, the contacts are shown in their normal state.

The ease of use of reversible magnetic starters cannot be overstated. This includes operational control of three-phase asynchronous motors of various machines and pumps, ventilation control and even control of shut-off valves, to locks and valves of heating systems. Particularly noteworthy is the possibility of remote control of magnetic starters, when the electronic remote control device switches the low-current coils of the starters as a relay, and they, in turn, safely switch the power circuits.