Modern Control Buttons and Push Buttons — Types and Types

Control buttons and push buttons are used for remote control of various electrical devices and machines. Most often, with the help of these means, they control equipment where electric motors are used as drives. In this way, the operator does not have to climb on the jib crane to bring the hook to the correct place in the workshop; instead, he simply needs to press the appropriate button on the control panel and the faucet will go where the operator points.

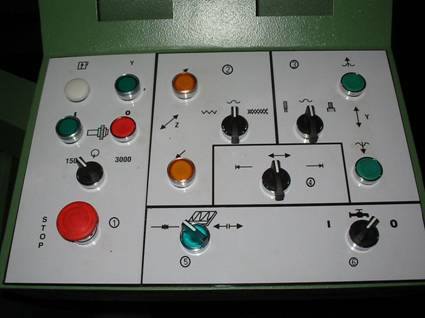

In a similar way, the power supply and operating modes of machines, fans, pumps, etc. are managed. Buttons and buttons can be located at the operator's workplace, forming a specialized panel for solving specific tasks related to the management of equipment in a given enterprise.

Button — an electrical control device consisting of a button (contact) and drive elements and is mainly intended for manual remote control of electromagnetic devices.

The buttons are used in AC circuits with a voltage of no more than 660 V and DC — no more than 440 V. There are two types: monoblock, in which the contact element and the drive are mounted in one block, and two — a block in which the drive (piston , handle, lock with key) is installed on a separate plate, and the button element is mounted on the base under the drive element. Buttons can have from 2 to 8 contacts, with the number of normally open contacts usually equal to the number of normally closed contacts.

After pressing the drive element stops, it, together with the contacts, under the action of return springs comes to its original position. There are buttons without self-return — with a lock with mechanical or electromagnetic control. Modern button designs use double-open-circuit bridge-type movable contacts. The contact material is silver or metal-ceramic composition.

The continuous current and the switching alternating current do not exceed 10 A. The pushing force of the button drive is 0.5 — 2 kg. For reasons of operational safety, the buttons that perform the "stop" command protrude 3 - 5 mm above the level of the control panel cover where they are installed, and the buttons that perform the "start" command are recessed to the same distance.

According to the degree of protection against the influence of the environment, the buttons are differentiated into open, protected and dustproof versions. Several buttons built into one shell or installed on one cover form a button (station) with a button.

Button posts are intended for turning on and off electrical devices, for changing the direction of rotation of drives in devices, for manual emergency shutdown of equipment in emergency situations, etc. — depending on the purpose of one or another electrical equipment.

In general, it can be noted that for different tasks, pushbuttons are performed in different cases and with different numbers of buttons, but one feature is fundamentally important - pushbutton posts are not used in high-voltage circuits, they can, of course, to control high-voltage equipment, but themselves operate in circuits with voltages up to 600 volts AC or 400 volts DC.

Often the current through a push-button is not the operating current of the installation. The switching of the power circuits is done by the starter, but the push-button station controls the starter.

For example, the connection of an asynchronous motor to the network directly or vice versa is controlled by a magnetic starter, and the operator controls the starter using a station with three buttons: "forward start", "reverse start", "stop". By pressing the «start» button, the normally open contacts of the starter are closed according to the direct engine start scheme, and by pressing the «reverse start» button, the contacts change their configuration to reverse. «Stop» - the starter opens the supply circuit.

The number of buttons on a button post is determined by the purpose of users and their number. So there are two-button and multi-button posts. In its simplest form, there are only two buttons "Start" and "Stop". And sometimes only one button installed, for example, on a lathe, is enough.

The buttons can be located in a metal or plastic housing, which in turn is mounted in a place that is more convenient to use. Separately, it is possible to set aside control posts for supporting cranes (PKT posts — button lifter with button).

The main element of the push button is the button. The buttons are of two types: self-adjust and lock. Self-returning ones are pushed to their original state by a spring — the operator has pressed the «Stop» button — the «Start» button returns to its original state, and those with fixation — only after pressing again — until you press again — the contacts will not open.

An example of a button with a latching button is a popular post with two buttons: the "Stop" button is pressed - the contacts are open, the "Start" button is in the free state. The «Start» button is pressed - the contacts are closed, and the «Stop» button is in a free state. These stations serve a myriad of applications and often operate with magnetic starters rather than supplying current directly.

Depending on the operating conditions and the degree of electrical safety, the material of the push button housing can be plastic or metal, and sometimes the buttons are simply installed without a housing on the outside of the device. As for the buttons themselves, they differ in shape and color. In terms of shape, they are subdivided into: concave, mushroom-shaped and cylindrical, and by color: red or yellow colors are typical for Stop buttons, and blue, white, green and black for Start buttons.

The range of push buttons on the market today is very wide, but basically they all work on the same principle. Posts from the «PKE» (single) series are particularly popular.They can be found on woodworking machines, on simple routers, etc. These buttons are capable of directly switching currents up to 10 A at an alternating voltage of 660 volts.

PKE series button stands are marked with numbers that can be deciphered. The first digit indicates the order in the series, the second - the method of installation (surface-mounted / built-in), the third - the degree of protection, the fourth - the material of the case (plastic / metal), the fifth - the number of controlled contacts, the sixth - the degree of modernization, the seventh - climatic version in accordance with the placement category.

The stations of the "PKU" series are special stations for explosive environments with a low concentration of gas and dust. These publications are basically similar to the PKE series, although they have their own designation system: the first number is the row of the series, the second is the modification number, the third is the rated current for the button, the fourth is the number of buttons in the horizontal rows, the fifth is the number of buttons in the vertical rows, the sixth — the installation method (mounted / indoor / suspended), the seventh — the degree of electrical protection, the eighth — the climatic version in accordance with the placement category.

PKT series stations are consoles for hoists, overhead cranes and overhead cranes. Their parameters are similar to the previous series. It is indicated by three indexes: the first is the series number, the second is the number of buttons, the third is the climate version according to the placement category.

Posts of the "KPVT" and "PVK" series are explosion-proof consoles. They are used in coal mines, paints and varnishes, etc.

Schneider Electric push buttons and switches: