Permanent magnets — types and properties, forms, interaction of magnets

What is a permanent magnet

A ferromagnetic product capable of retaining significant residual magnetization after removal of the external magnetic field is called a permanent magnet.

Permanent magnets are made from various metals such as cobalt, iron, nickel, rare earth alloys (for neodymium magnets) as well as natural minerals such as magnetites.

The scope of application of permanent magnets today is very wide, but their purpose is fundamentally the same everywhere — as a permanent magnetic field source without power supply… Thus a magnet is a body that has its own magnetic field.

The very word "magnet" comes from the Greek phrase that translates as "Stone of Magnesia", named after the Asian city where deposits of magnetite - a magnetic iron ore - were discovered in ancient times… From a physical point of view, an elementary magnet is an electron, and the magnetic properties of magnets are usually determined by the magnetic moments of the electrons that make up the magnetized material.

The permanent magnet is a part magnetic systems of electrical products… Permanent magnet devices are generally based on energy conversion:

-

mechanical to mechanical (separators, magnetic connectors, etc.);

-

mechanical to electromagnetic (electrical generators, speakers, etc.);

-

electromagnetic to mechanical (electric motors, loudspeakers, magnetoelectric systems, etc.);

-

mechanical to internal (brake devices, etc.).

The following requirements apply to permanent magnets:

-

high specific magnetic energy;

-

minimum dimensions for a given field strength;

-

maintaining performance over a wide range of operating temperatures;

-

resistance to external magnetic fields; — technology;

-

low cost of raw materials;

-

stability of magnetic parameters over time.

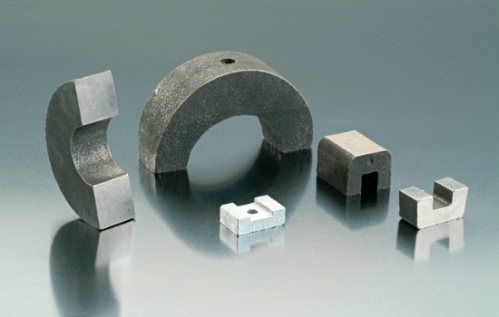

The variety of tasks solved with the help of permanent magnets necessitates the creation of many forms of their implementation. Permanent magnets are often shaped like a horseshoe (the so-called "horseshoe" magnets).

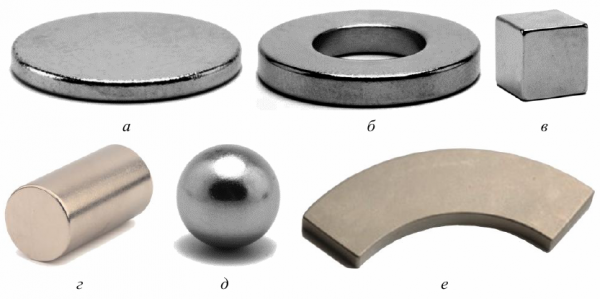

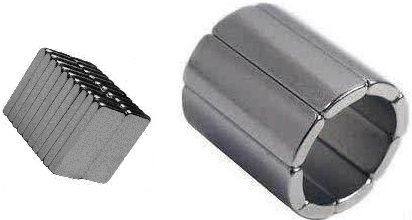

The figure shows examples of forms of industrially produced permanent magnets based on rare earth elements with a protective coating.

Commercially produced permanent magnets of various shapes: a — disc; b — ring; c — parallelepiped; g — cylinder; d — ball; e — sector of a hollow cylinder

Magnets are also produced from hard magnetic metal alloys and ferrites in the form of round and rectangular rods, as well as tubular, C-shaped, horseshoe-shaped, in the form of rectangular plates, etc.

After the material is shaped, it must be magnetized, that is, placed in an external magnetic field, because the magnetic parameters of permanent magnets are determined not only by their shape or the material from which they are made, but also by the direction of magnetization.

The workpieces are magnetized using permanent magnets, DC electromagnets or magnetizing coils through which current pulses pass. The choice of magnetization method depends on the material and shape of the permanent magnet.

As a result of strong heating, impacts, permanent magnets can partially or completely lose their magnetic properties (demagnetization).

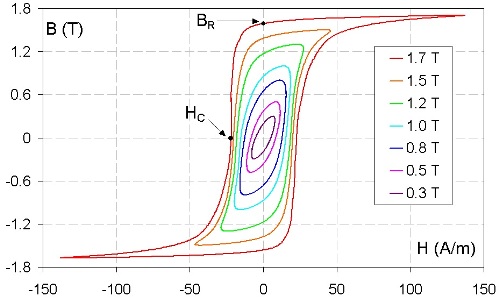

Characteristics of the degaussing section magnetic hysteresis loops the material from which a permanent magnet is made determines the properties of a particular permanent magnet: the higher the coercive force Hc and the higher the residual value magnetic induction Br — the stronger and more stable magnet.

Coercive power (literally translated from Latin — "holding force") — a force that prevents a change in magnetic polarization ferromagnets.

As long as the ferromagnet is not polarized, that is, the elementary currents are not oriented, the coercive force prevents the orientation of the elementary currents. But when the ferromagnet is already polarized, it maintains the elementary currents in an oriented position even after the external magnetizing field is removed.

This explains the residual magnetism seen in many ferromagnets. The greater the coercive force, the stronger the residual magnetism phenomenon.

So coercive power is magnetic field strengthrequired for complete demagnetization of a ferro- or ferrimagnetic substance. Thus, the more coercive a certain magnet has, the more resistant it is to demagnetizing factors.

A unit of measurement of coercive force in NE — Ampere / meter. A magnetic induction, as you know, is a vector quantity, which is a force characteristic of the magnetic field. The characteristic value of the residual magnetic induction of permanent magnets is of the order of 1 Tesla.

Magnetic hysteresis — the presence of the effects of the polarization of magnets leads to the fact that the magnetization and demagnetization of the magnetic material proceeds unevenly, since the magnetization of the material all the time lags slightly behind the magnetizing field.

In this case, part of the energy spent on magnetizing the body is not returned during demagnetization, but turns into heat. Therefore, repeatedly reversing the magnetization of the material is associated with noticeable energy losses and can sometimes cause strong heating of the magnetized body.

The more pronounced the hysteresis in the material, the greater the loss in it when the magnetization is reversed. Therefore, materials that do not have hysteresis are used for magnetic circuits with alternating magnetic flux (see — Magnetic cores of electrical devices).

The magnetic properties of permanent magnets can change under the influence of time and external factors, which include:

-

temperature;

-

magnetic fields;

-

mechanical loads;

-

radiation etc.

The change in magnetic properties is characterized by the instability of the permanent magnet, which can be structural or magnetic.

Structural instability is associated with changes in the crystal structure, phase transformations, reduction of internal stresses, etc. In this case, the original magnetic properties can be obtained by restoring the structure (for example, by heat treatment of the material).

Magnetic instability is caused by a change in the magnetic structure of the magnetic substance, which tends to thermodynamic equilibrium over time and under the influence of external influences. Magnetic instability can be:

-

reversible (return to initial conditions restores original magnetic properties);

-

irreversible (the return of the original properties can be achieved only by repeated magnetization).

Permanent magnet or electromagnet — which is better?

Using permanent magnets to create a permanent magnetic field instead of their equivalent electromagnets allows:

-

to reduce the weight and size characteristics of the products;

-

excludes the use of additional energy sources (which simplifies the design of products, reduces the cost of their production and operation);

-

provide an almost unlimited time to maintain the magnetic field in working conditions (depending on the material used).

The disadvantages of permanent magnets are:

-

fragility of the materials used in their creation (this complicates the mechanical processing of the products);

-

the need for protection against the influence of moisture and mold (for ferrites GOST 24063), as well as against the influence of high humidity and temperature.

Types and properties of permanent magnets

Ferrite

Ferrite magnets, although fragile, have good corrosion resistance, making them the most common at low cost. These magnets are made of an alloy of iron oxide with barium or strontium ferrite. This composition allows the material to retain its magnetic properties in a wide temperature range — from -30 ° C to + 270 ° C.

Magnetic products in the form of ferrite rings, rods and horseshoes are widely used both in industry and in everyday life, in technology and electronics. They are used in speaker systems, in generators, in DC motors… In the automotive industry, ferrite magnets are installed in starters, windows, cooling systems and fans.

Ferrite magnets are characterized by a coercive force of about 200 kA/m and a residual magnetic induction of about 0.4 Tesla. On average, a ferrite magnet can last 10 to 30 years.

Alnico (aluminum-nickel-cobalt)

Permanent magnets based on an alloy of aluminum, nickel and cobalt are characterized by unsurpassed temperature stability and stability: they are able to maintain their magnetic properties at temperatures up to + 550 ° C, although their coercive force is relatively small. Under the influence of a relatively small magnetic field, such magnets will lose their original magnetic properties.

Judge for yourself: a typical coercive force is about 50 kA / m with a residual magnetization of about 0.7 Tesla. Despite this feature, alnico magnets are indispensable for some scientific research.

The typical content of components in alnico alloys with high magnetic properties varies within the following limits: aluminum — from 7 to 10%, nickel — from 12 to 15%, cobalt — from 18 to 40%, and from 3 to 4% copper.

The more cobalt, the higher the saturation induction and magnetic energy of the alloy. Additives in the form of 2 to 8% titanium and only 1% niobium contribute to obtaining a higher coercive force — up to 145 kA / m. The addition of 0.5 to 1% silicon ensures isotropic magnetic properties.

Samaria

If you need exceptional resistance to corrosion, oxidation and temperatures up to + 350 ° C, then a magnetic alloy of samarium with cobalt is what you need.

At a certain price, samarium-cobalt magnets are more expensive than neodymium magnets because of the scarcer and more expensive metal, cobalt. Nevertheless, it is recommended to use them if it is necessary to have minimum dimensions and weight of the final products.

This is most appropriate in spacecraft, aviation and computer technology, miniature electric motors and magnetic couplings, in wearables and devices (watches, headphones, mobile phones, etc.)

Because of its special resistance to corrosion, it is samarium magnets that are used in strategic development and military applications. Electric motors, generators, lifting systems, motor vehicles - a strong magnet made of samarium-cobalt alloy is ideal for aggressive environments and difficult working conditions. The coercive force is of the order of 700 kA/m with a residual magnetic induction of the order of 1 Tesla.

Neodymium

Neodymium magnets are in great demand today and seem to be the most promising. The neodymium-iron-boron alloy allows you to create super magnets for a variety of applications, from locks and toys to electrical generators and powerful lifting machines.

A high coercive force of about 1000 kA / m and a residual magnetization of about 1.1 Tesla allow the magnet to be maintained for many years, for 10 years a neodymium magnet loses only 1% of its magnetization if its temperature under operating conditions does not exceed + 80 ° C (for some brands up to + 200 ° C). Thus, there are only two disadvantages of neodymium magnets — fragility and low operating temperature.

Magnetoplasts

The magnetic powder together with the binder forms a soft, flexible and light magnet. Bonding components such as vinyl, rubber, plastic or acrylic allow magnets to be produced in a variety of shapes and sizes.

The magnetic force is, of course, lower than pure magnetic material, but sometimes such solutions are necessary to achieve certain unusual purposes for magnets: in the production of advertising products, in the production of removable car stickers, as well as in the production of various stationery and souvenirs.

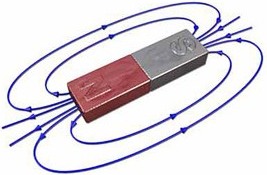

Interaction of magnets

Like the poles of magnets repel and unlike the poles attract. The interaction of magnets is explained by the fact that each magnet has a magnetic field and these magnetic fields interact with each other. For example, what is the reason for the magnetization of iron?

According to the hypothesis of the French scientist Ampere, inside the substance there are elementary electric currents (Ampere currents), which are formed due to the movement of electrons around the nuclei of atoms and around their own axis.

Elementary magnetic fields arise from the movement of electrons.And if a piece of iron is introduced into an external magnetic field, then all the elementary magnetic fields in this iron are oriented in the same way in an external magnetic field, forming its own magnetic field from a piece of iron. So if the applied external magnetic field was strong enough, once you switched it off, the piece of iron would become a permanent magnet.

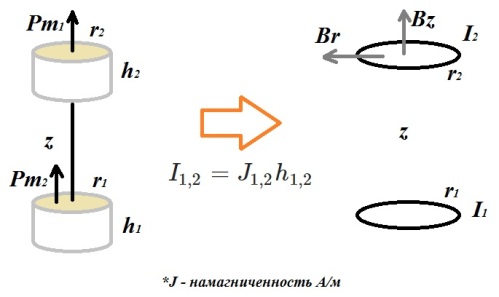

Knowing the shape and magnetization of a permanent magnet allows the calculations to be replaced by an equivalent system of electric magnetizing currents. Such a replacement is possible both when calculating the characteristics of the magnetic field and when calculating the forces acting on the magnet from the external field.

For example, let's calculate the interaction force of two permanent magnets. Let the magnets have the form of thin cylinders, their radii will be denoted by r1 and r2, the thicknesses are h1, h2, the axes of the magnets coincide, the distance between the magnets will be denoted by z, we will assume that it is much larger than the size of the magnets.

The appearance of the force of interaction between magnets is explained in the traditional way: one magnet creates a magnetic field that acts on the second magnet.

To calculate the interaction force, we mentally replace the uniformly magnetized magnets J1 and J2 with circular currents flowing on the side surface of the cylinders. The strengths of these currents will be expressed in terms of the magnetization of the magnets, and their radii will be considered equal to the radii of the magnets.

Let us decompose the induction vector B of the magnetic field created by the first magnet in place of the second into two components: axial, directed along the axis of the magnet, and radial, perpendicular to it.

To calculate the total force acting on the ring, it is necessary to mentally divide it into small elements Idl and sum Amperesacting on each such element.

Using the rule on the left, it is easy to show that the axial component of the magnetic field gives rise to Ampere forces that tend to stretch (or compress) the ring—the vector sum of these forces is zero.

The presence of the radial component of the field leads to the appearance of Ampere forces directed along the axis of the magnets, that is, to their attraction or repulsion. It remains to calculate the Ampere forces — these will be the forces of interaction between the two magnets.

See also:The use of permanent magnets in electrical engineering and energy