Kinetic energy storage devices for the power industry

The topic of improving energy efficiency will probably never lose its relevance. Due to this fact, many institutions today are developing more efficient energy storage devices. And one of the promising solutions in this area is the use of kinetic (in motion) energy storage based on high-energy flywheels.

The topic of improving energy efficiency will probably never lose its relevance. Due to this fact, many institutions today are developing more efficient energy storage devices. And one of the promising solutions in this area is the use of kinetic (in motion) energy storage based on high-energy flywheels.

Their areas of application can vary from small independent uninterruptible power supplies for private households to large industrial installations that accumulate energy during the rotation of a flywheel and at the right time release it at the required power level, protecting the network from voltage surges.

The advantage of such units is that the massive flywheel is able to immediately convert the accumulated kinetic energy into electrical energy, thereby providing the consumer equipment with the necessary power.

Such devices are characterized by minimal operating costs, a high degree of automation and no need for regular maintenance.

After charging to full capacity in a few minutes, the flywheel will release the stored energy if needed for a few seconds, while the normal operating parameters of the network may not withstand high peak currents.

How it works

The flywheel receives rotation from an electric machine through a shaft or through another transmission mechanism and, if necessary, gives the accumulated energy through the shaft in generator mode, and the machine that rotates the flywheel itself can work at that moment as a generator.

An automated control system with sensors for controlling parameters will make the process of gaining speed safe and in a critical situation will react both to the achievement of a dangerous speed of rotation of the flywheel and to the need to immediately switch to the mode of returning the accumulated kinetic energy .

Features and capabilities

In this way, kinetic storage devices allow to solve the problems of accumulation, temporary storage and subsequent conversion of energy to ensure optimal equipment power modes, even with extremely non-standard parameters. As a result, the widest range of possible applications of this technical solution is covered.

An electromechanical converter of this type has a number of advantages. The specific energy intensity of kinetic storage devices is higher than that of capacitors, and in terms of specific power (current) delivered to the load, they are ahead of both acid batteries and fuel cells.

At the same time, kinetic storage devices are compact, environmentally friendly, have an efficiency of about 90%, have a long service life of more than 10 years, are easy to maintain, and the working resource is practically unlimited, in addition, the cooling system is a hundred times cheaper than that of superconducting induction storage devices (SPINs). …

Medical centers, nuclear facilities, data storage centers, bank warehouses, chemical industries—anywhere energy backup is required to power critical users, kinetic storage devices will come in handy. What can we say about offsetting peak loads for large power systems, which is why there are power outages to entire urban areas.

What is used now

For ten years, the development of kinetic storage devices has not stopped in several regions of the world, especially in the USA and Germany, and in recent years in Russia.

Germany's ATZ produces 20 MJ drives capable of delivering power up to 250 kW, equipped with a grid synchronization system. In addition, the dimensions of the device do not exceed 1.5 meters.

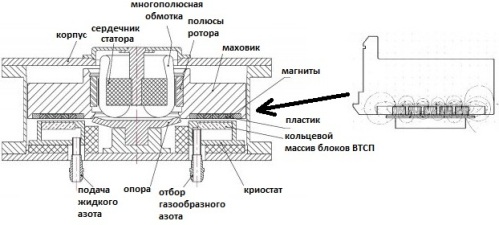

The drive flywheel is made of high-strength carbon fiber and is mounted on an HTSC ceramic suspension. The electric machine that accelerates the flywheel of the ATZ and generates electricity is complete based on permanent rare earth magnets.

American Beacon Power produces cylindrical storage devices for 6 kWh and 25 kWh that can be used in clusters to ensure the stability of current parameters in the country's industrial electric grids.

KNE design stages

When designing a kinetic storage device, developers solve the following engineering problems: calculate the motor-generator, select the bearings, calculate the flywheel, as well as the cooling, monitoring and control systems, and then proceed to production.

Based on the purpose of a specific drive model, the electric machines integrated in them can be different in principle. However, there is an undeniable advantage synchronous electric machines… In synchronous machines, there are no brushes, and the permanent magnets of the rotor make it possible to obtain a high specific power of the motor-generator.

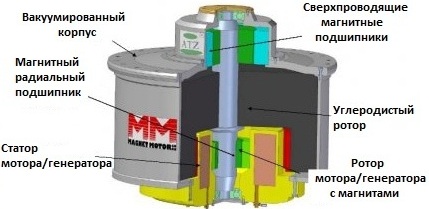

Bearings and suspensions are best suited for non-contact bearings, such as those based on high-temperature superconductors (HTSC).

Although such systems require special cooling, they are nevertheless perfectly stabilized without power supply: an inductor of a set of permanent magnets interacts with a HTSP matrix in a superconducting state. There are no frictional losses, even in air, vibrations are minimal even at high speeds, and the structure is automatically centered during operation.

An example of a device developed at the Russian MAI

The magnetic field of permanent magnets interacts with the activated HTSP blocks, and after installing the support, the flywheel simply leans over the cryostat (levitates over it at a distance of less than 1 cm), while not moving in the radial direction.

The electromagnetic interaction of the stator and rotor poles creates a resultant torque that accelerates the flywheel and thus energizes the drive.And since there are no losses in the supports accumulated in kinetic form, the energy is stored for a long time and, if necessary, consumed by conversion to generator mode.

In the process of accumulating the full nominal 500 kJ of energy, the flywheel is accelerated in 300 seconds to 6000 revolutions per minute. It can easily supply a power of 10 kW for 25 seconds continuously, since the rated power taken from the plant is 250 kJ respectively, a load of 1 kW can be guaranteed to be supplied for 4 minutes.

The input voltage frequency when charging is 50 Hz at a standard mains voltage of 220-240 volts. The flywheel weighs 100 kg and the moment of inertia is approximately 3.6 kg * m2.

As for the generator mode, the current frequency during selection is 200 Hz on three phases at voltages from 160 to 240 volts. The maximum rated power for selection is 11 kW.

Prospects for Russia and the CIS

More recently, the Russian company Kinetic Power has created its own version of stationary kinetic energy storage devices based on super flywheels. One such storage device is capable of storing up to 100 kWh of energy and providing short-term power of up to 300 kW.

In the conditions of the Russian market, a group of several such storage devices is able to equalize the daily heterogeneity of the electric load of an entire region, replacing expensive and bulky pumped power plants.

Additionally, as noted at the outset, kinetic storage devices can be used to provide uninterrupted power to equipment with the highest levels of responsibility.The unique properties of these developments ensure a response of the device at the level of hundredths of a second, which allows users not to interrupt the power supply for a second.