The principle of operation of inductive proximity switches, varieties and examples of their use

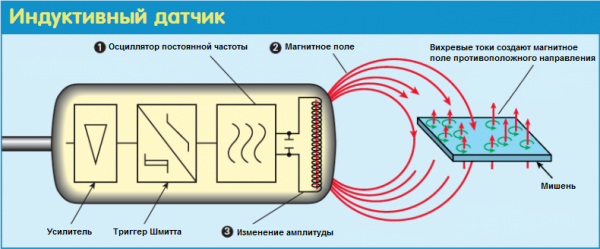

Contactless inductive switches (proximity sensors) are used for automated non-contact detection of objects with various industrial purposes. The principle of their operation is based on the phenomenon of a change in the oscillation amplitude of the generator associated with the introduction of a ferromagnetic, magnetic or metallic object of a certain size into the working area of the sensor.

When the sensor is turned on, an alternating magnetic field acts in its working area, and if now metal is introduced into this area, then the targets are directed to this metal eddy currents will cause a change in the initial oscillation amplitude of the generator, while the magnitude of the change will depend on the distance between the metal object and the sensor. The corresponding value of the analog signal will be converted by the flip-flop into a logic signal, which will determine the hysteresis value and the switching level.

The switch itself in this context is a semiconductor converter that controls the state of a certain external trigger circuit depending on the location of the observed object, and the position of the object is determined without mechanical contact with the sensor.

As you've probably already figured out, the sensitive element here is inductor, whose magnetic circuit is open in the direction of the working area.

Inductive limit switches belong to a large group non-contact sensors for the position of mechanisms, which are very common in modern automatic systems.

The inductive proximity switch in a certain automation system acts as the main tool for monitoring the position of certain items of equipment, the signals from which are processed, depending on the purpose of the equipment, from the product counter, motion controller, alarm system, etc. n. .

In particular, inductive proximity switches are often used to count metal objects and track their position, for example, bottles move along a conveyor, on whose caps they are counted, or in an assembly shop, a tool change occurs after the counter, the flange is in the range of an inductive sensor. …

The operation process of the switch can be described as follows. In the working state, a magnetic field with a constant amplitude pulses in front of the working surface of the non-contact sensor.

If the metal comes close to the sensor (for example, a tin cap of a bottle or a part of a part involved in a robotic assembly), then there will be a tendency to dampen the oscillations of the magnetic field, accordingly, the value of the demodulated voltage will drop, the trigger is triggered, which leads until the switching element is switched (e.g. until a counter is actuated or until the tool is changed).

All metal objects of sufficient size, for example: shaft protrusions, flanges, steel plates, coupling bolt heads, etc., can serve as control or counting objects for non-contact inductive switches.

According to the commutation principle of the controlled circuit and the method of connection to it, inductive sensors are available in several varieties, with different numbers of wires. Sensors are built on the basis of NPN or PNP switches, they can be normally closed or normally open.

Two-wire - they are connected directly to the load circuit and are powered through it, here it is very important to observe the polarity and nominal load resistance, otherwise the sensor will not work properly.

Three-wire switches are the most common, they have power on two wires, and the third is used to connect the switched load.

Finally, four-wire switches have the ability to select the switching mode (normally closed or normally open).

Another common type of position sensors in modern automatic systems: Optical proximity switches