Laser thermometers — device, principle of operation and application

There are many industrial sectors where it is most convenient to measure the temperature without contact of the thermometer with the object, for example in the steel industry in metallurgy, in transport maintenance or in the repair of gas pipelines. And in everyday life there are many such circumstances: to measure the temperature of a dish, a cup or a human body.

One way or another, there are many situations where, in conditions of high temperature of the object, there is nothing more convenient and safer than resorting to using a portable laser pyrometer (laser thermometer). The price of such a device depends on both the manufacturer and the operating parameters and the seller. Today it can be purchased from $ 10 and up.

Unlike contact methods of temperature measurement with various temperature sensors, the laser pyrometer is equipped with a kind of laser sight, so it is enough to direct the laser beam at the object being examined at a distance of up to three meters, and the pyrometric converter will automatically start to works further and the user can only see the temperature value. on the display of a high-precision engineering device — everything is very simple.

The main condition for successful measurements is that the surface of the object is neither reflective nor completely transparent.

In appearance, a laser thermometer or pyrometer looks like a laser gun with a screen from some fantasy movie. But in fact, this is just a convenient form for a device that will be convenient for a worker to hold in his hand, the device is equipped with a control panel and LCD display, and thanks to a laser designator, the user gets high accuracy of aiming and quick results.

The principle of temperature measurement is based on analysis. electromagnetic infrared (heat) radiationintensely radiating from the surface of any heated object. This allows today to quickly monitor and control the temperature conditions of objects, parts, elements, etc.

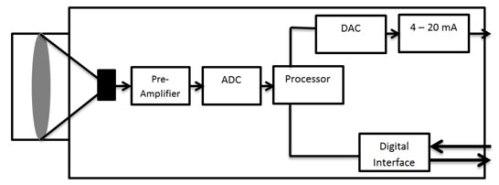

The design of the pyrometer is based on a thermal radiation detector (IR detector). The conclusion is that the spectrum and intensity of the infrared radiation emitted by an object during the measurement is directly related to the current temperature of its surface.

An electronic pyrometric converter converts the absolute value of the wavelength of the energy emitted in the infrared spectrum into a form convenient for human visual perception on the display. The user simply points the device at a distant object and the distance is limited by the size of the examined spot and air pollution, after which the device indirectly determines the exact temperature value. One has to press a 'trigger'-like button and hold it to fix the received data.

The laser thermometer has the following features. The range of measured temperatures is from -50 to + 4000 ° C. Optical resolution from 2 to 600. Object diameter — not less than 15 mm. The reading speed is less than one second, which allows you to monitor the temperature in dynamics. The dimensions of the device, as a rule, are small, it fits easily in the hand, and the information is easy to read from the digital display.

Some models also have additional features, such as:

-

storing measurement information in the built-in memory of the device;

-

finding the minimum and maximum temperature from a series of measured values;

-

sound or visual signal at the moment when the temperature reaches the specified threshold;

-

ability to transfer data via USB to a computer or to a USB flash drive.

Whether for domestic use to change the temperature of food, or for use in some industrial sectors, such as measuring the temperature of a hot water pipe, an inexpensive laser pyrometer is suitable.

In general, laser pyrometers are popular in many industries: in research laboratories, in the energy sector, in the food industry, in metallurgy, to check the operating modes of electrical equipment, to study bearings and internal combustion engines, to analyze the state of computer systems in military, civil and industrial construction.

Laser thermometers (pyrometers) are not only mobile, but also stationary. Stationary ones are widely used to monitor the condition of infrastructure facilities, of refrigerated vehicles, to monitor the conditions of transportation of medicines and food, and finally, they are equipped with fire teams.

In general, the reasons for using pyrometers can be mainly divided into the following:

-

the object is inaccessible for contact — to measure the temperature at a remote, inaccessible object;

-

the object is dangerous for contact — checking the operating mode of the object that is under voltage;

-

express observation — the temperature of the surfaces changes rapidly during their examination;

-

the low thermal conductivity of objects requires fixing the surface temperature.