Power transformer cooling systems

Normal long-term trouble-free operation power transformers subject to control and compliance with the permissible limits of various parameters, one of which is the temperature regime. Compliance with the temperature regime within the limits established for a certain type of transformer is ensured by specially provided cooling systems. Consider what cooling systems are for power transformers.

Cooling type C, SG, SZ, SD

The letter C in the marking indicates this dry power transformer — that is, it does not provide for the use of transformer oil for cooling. In this case, the windings and the magnetic core of the transformer are cooled by natural air circulation. There are modifications of this cooling system: SG — hermetic design, SZ — protective housing.

The presence of forced air circulation on the transformer housing is possible — this is the cooling of the LED system.

Cooling systems C and their modifications are characterized by low efficiency, which is why they are used in low-power transformers, as a rule, up to 1.6 MV * A of voltage class 6 and 10 kV.

Temperature sensors are installed on the transformers of this cooling system to control the temperature for each phase of the transformer.

Cooling system M

More powerful transformers require a more efficient cooling system — oil. The oil provides more efficient heat removal from the windings and magnetic system of the transformer, providing uniform cooling.

The cooling system M ensures the natural circulation of the oil in the transformer tank. The heat of the oil is transferred to the transformer tank, which is cooled by the ambient air. This cooling system does not provide forced air circulation.

For more efficient cooling of the transformer tank, radiators consisting of fins or tubes through which the oil circulates are installed.

Cooling system M is used for power transformers with rated power up to 16 MV * A. The absence of additional devices in the design of transformers of this cooling system simplifies their operation.

Maintenance personnel only need to check the oil level and the temperature of its upper layers. The oil level should approximately correspond to the average daily ambient temperature, taking into account the load on the transformer (this applies to all types of cooling). The temperature of the upper oil layers of M and D cooled transformers should not exceed 95 degrees.

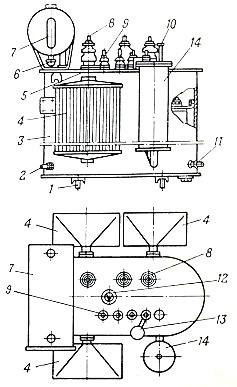

The figure below shows a three-phase two-winding transformer with natural oil cooling (with natural oil circulation) of the TM-250 / 6-10-66 series with a capacity of 250 kVA, designed for the conversion of alternating three-phase current with a voltage of 6 — 10 kV from VN side, NN side 0.23; 0.40; 0.69 kV for indoor and outdoor installation.

Power series TM-250 / 6-10 with thermosiphon filter for continuous oil purification: 1-rolls; 2 — grounding bolt; 3 — tank; 4 — removable radiator coolers; 5 — cover; 6 — silikogel air dryer; 7 — expander with an oil indicator; 8 — conclusions BH; 9 — LV conclusions; 10 — mercury thermometer; 11 — plug for filling and oil sampling; 12 — switch; 13 — damage fuse; 14 — thermosiphon purifying filter for continuous oil.

D type cooling

Transformer cooling system D — with blowdown and natural oil circulation. The transformers of this cooling system by design have fans mounted in hinged radiators through which the transformer oil circulates.

The transformer blowdown of this cooling system is turned on when the temperature of the upper layer of the transformer oil reaches 55 degrees or more, or when the rated load of the transformer is reached, regardless of the oil temperature. Cooling system D is more efficient and is used for transformers rated 16-80 MV * A.

Cooling systems DC, NDC

The direct current cooling system differs from the D system by the presence of forced oil circulation. Blowing fans, as in the D system, cool the radiator tubes.Transformer oil is continuously circulated through the radiator tubes, which is pumped by electric pumps built into the oil lines of the transformer tank.

The rapid circulation of oil through the radiators and their air flow ensure high heat transfer. Thanks to this cooling system, the dimensions of the power transformer (autotransformer) are significantly reduced and their nominal power is increased to the limits of 63-160 MV * A.

Forced oil circulation makes it possible to deviate from traditional transformer design — the transformer tank and cooler can stand separately, connected to each other by oil lines.

Unlike D-type cooling, DC cooling blowers must always be operated together with forced oil circulation pumps. In the event of a shutdown of one of the cooling systems, the transformer cannot operate.

NDC differs from DC cooling in the presence of a directional flow of oil, which makes it possible to increase the cooling efficiency and, accordingly, increase the power of the transformer without changing its size.

Cooling systems Ts, NTs

Transformers and autotransformers with a capacity of 160 MV * A are equipped with T-type cooling systems. This is oil-water cooling; not only oil but also water is circulated through the radiators of the transformer.

The water is forced to circulate through the pipes of the cooling device, between which, in turn, the transformer oil circulates.Before entering the cooler, special temperature sensors are installed to control the temperature of the circulating oil, which should not exceed 70 degrees.

Devices for forced circulation of oil and water must always be in operation, regardless of temperature and load, they must be turned on automatically simultaneously with the supply of voltage to the transformer (autotransformer).

In the presence of structurally several cooling devices, the number of their simultaneous operation is determined by the size of the load and the temperature of the cooling medium - transformer oil.

This cooling system is one of the most efficient systems, but its main disadvantage is the complexity of design and operation.

For transformers (autotransformers) with a capacity of 630 MV * A, a more efficient oil-water cooling system with directed oil flow — NC is used.

Cooling of transformers in closed chambers

In closed chambers, closed transformer substations, where power transformers are located, a ventilation system must be provided that ensures the normal operation of transformers in all standardized modes.

The room in which the power transformer is located must be designed in such a way that during operation the transformer does not overheat, which is guaranteed if there is sufficient internal space in the room, as well as an effective ventilation system.

Special attention is paid to the transformers of the cooling system C, which are cooled by natural air circulation.Forced ventilation is installed in the chambers of this type of transformers, which circulates the air for more efficient cooling.