Rubber and rubber materials: rubber, ebonite, gutta-percha, balata

Rubber This is the generic name under which the coagulation product of the milky sap secreted by certain tropical plants is sold. These plants include the Brazilian hevea (Hevea brasiliensis) and its related species. About 9/10 of the world's rubber production comes from both wild and plantation hevea.

Plantation rubber is superior in quality to wild rubber. Commercial rubber has various names, the most valuable grade being «para-rubber». Chemically, the main component of rubber is a hydrocarbon composition (С10З16)n. Currently, synthetic rubber is produced in large quantities by polymerization of isoprene (C538). Rubber is soluble in gasoline, benzene, carbon disulfide, etc.

Even before the discovery of Brazil, the native Indians had "rubber balls", bottles of unbreakable material, and used torches for lighting on holidays, which burned for a long time, but gave off a lot of soot and had a pungent smell. They are made from the milky white "tears" of the rubber tree.

Samples of this material in the form of rubbery dry cakes were brought home by the French explorer and scientist Charles Marie de la Condamine in 1744 during the British naval blockade of France. But rubber gained industrial importance only after the American chemist Charles Nelson Goodyear in 1839 succeeded in converting rubber with sulfur under the action of heat from plastic to an elastic state (rubber).

As a result of the process of vulcanization and production of ebonite, in 1848 he became the founder of the modern rubber industry. In 1898, the Goodyear Tire & Rubber Company was founded in Akran, Ohio. Even today, it is one of the largest producers of rubber and synthetic rubber products in the world.

Rubber processing

In its pure form, rubber is not used, but is pre-mixed with various substances, of which sulfur plays a major role. The resulting mixture is molded and vulcanized. Mixing is done by grinding the rubber on rollers, with the gradual addition of one or another substance.

The composition of the rubber mass may include the following substances:

-

rubber;

-

rubber surrogates (reclamation — old rubber and facts — sulfur vulcanized fatty oils);

-

fillers (zinc oxide, chalk, kaolv, etc.);

-

sulfur;

-

vulcanization accelerators;

-

softeners added with a large percentage of fillers (paraffin, ceresin, asphalt, etc.);

-

dyes.

In electrical engineering, soft rubber is used, with a high content of fillers (up to 60% and more), but with a low sulfur content, and hard rubber - horn rubber, ebonite, with a high sulfur content.

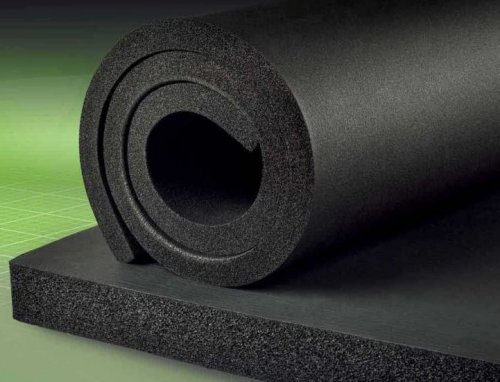

Rubber

Rubber is a mixture of rubber and sulfur processed at an elevated temperature. Extremely flexible, elastic, completely waterproof material with high insulating properties.It is produced in the form of sheets of different thicknesses and is widely used to insulate wires. The negative qualities are low heat resistance and oil resistance.

VulcanizationI am

For electrical products, extremely hot vulcanization is used. The vulcanization temperature is 160 — 170 ° C for hard rubber and 125 — 145 ° C for soft rubber. The vulcanization time depends on the type of products and their size.

In order to speed up the vulcanization process, special substances of organic and inorganic origin - accelerators - are added to the scum mixture. These substances include oxides of some metals as well as some complex organic compounds. I have accelerators not only reduce the vulcanization time by 4-6 times, but also give a more homogeneous product and in all respects the best qualities.

Crushed properties of rubber

The properties of rubber depend on its type, type of filler, amount of sulfur, vulcanization time, etc. Increasing the sulfur content increases the dielectric constant angle and loss angle. Of the impurities, carbon black has the most harmful effect on electrical properties, and ground quartz is the least harmful.

Oudsmruch aboutbcapacitance resistance is on average 1014 — 1016 Ohm x cm… Dielectric constant from 2.5 to 3. Electrical strength for raw rubber — 24 kV / mm, for vulcanized rubber — 38.7 kV / mm… Loss tangent for vulcanized rubber 0.005 — 0.02. Oudspruch weight of pure rubber 0.93 — 0.97, rubber mixture — 1.7 — 2. Temporary resistance resistance NSand stretching good rubber — 120 kg / cm2, in addition, when tearing, the rubber is extended by 7 times .

Soft rubber is mainly the insulation of wires, for the production of pipes, tapes, gloves, etc.During electrical work, insulating tape is widely used, which is a simple ordinary tape covered on one side with a rubber adhesive mass.

Ebonite

Also called hard rubber. The best brands of ebonite contain 75% pure rubber and 25% sulfur. Some varieties also contain recovery and fillers. Sometimes, however, fillers are added to change the properties of ebonite in the desired direction, for example, imer to increase its heat resistance.

Oudsmruch about bCapacitive resistance of the best grades of ebonite goes up to 1016 — 1017 Ohm x cm. Surface resistance up to 1015 Ohm... However, the surface resistance is significantly reduced with prolonged exposure to light rays. To reduce this effect, the ebonite surface should be well polished.

Aging occurs due to the release of free sulfur from the ebonite, which combines with atmospheric oxygen and moisture to give sulfuric acid. To restore the surface. the ebonite is washed first with ammonia and then repeatedly with distilled water.

The electrical strength of eboint is from 8 to 10 kV / mm at thicknesses of the order of 5 - 10 mm ... Maximum bending strength from 400 to 1000 Kilograms / ° Cm2 ... Temporary resistance in impact bending 5 - 20 (kg x cm) / cm2 … Heat resistance 45 — 55 ° C.

Enterprises producing ebonite usually produce several varieties of it. The lower the grade, the more rubber substitutes and fillers it contains. Ebonite is widely used in electrical engineering.. Ebonite is sold in sheets, rods and tubes.

Special grades of ebonite include acestonite and volcano-asbestos.Their production is slightly different from the production of ebonite, namely: since the asbestos fibers are completely ground with rollers, the rubber is dissolved in gasoline and then mixed with asbestos and other fillers. Such mixtures can contain very little rubber, up to 10%, as a result of which the heat resistance of these products can increase up to 160 ° C.

Ebonite powder is used to produce plastics from which various insulating parts are pressed.

Synthetic artificial rubber

In the modern cable industry, not natural rubber is preferred, but its synthetic types and mixtures. These mixtures give specific properties to the insulating layer and sheath of finished products (wires, wires and cables). Additives are added to the mixtures that accelerate the crosslinking reaction, as well as color pigments and additives that protect the final product from aging.

There are several types of synthetic rubber — carboxylate, polysulfide, ethylene propim, etc. The electrical properties of synthetic rubber are close to those of natural rubber, but the mechanical properties are lower.

Gutta-percha

Gutta-percha is a product of coagulation of the milky juice of certain plants growing on the islands of the Malay Archipelago.

Gutta-percha contains 20-30% resins and 70-80% rubber with hydrocarbons, and its chemical composition is close to natural rubber. But since relatives are not always alike, gutta-percha also behaves differently from natural rubber. At a temperature of 50-70 OC gutta-percha it becomes plastic, but not elastic, like rubber, and hardens when exposed to cold.

Gutta-percha does not heal. It begins to soften at 37 ° C, at 60 ° C it becomes completely plastic and at 130 ° C it melts. Oudsmruch volumetric resistance 1014 — 1016 Ohm x cm.

It is one of the oldest electrical insulating materials. Since 1845, telegraph wires in Great Britain have been insulated with gutta-percha, incl. for insulation of underwater lines.

Underwater telegraph cable 1864

In the seventies of the XIX century, the first cable factories appeared abroad and in Russia. These factories mainly make insulated wire for the telegraph, and a few make gutta-percha insulated submarine telegraph cable.

The use of new raw materials such as rubber, gutta-percha and balata was supported by Franz Klout (1838 - 1910), born in Cologne, who became an innovator and the most important founder of the rubber industry in Germany.

Experiments with gutta-percha as an insulating lining were also carried out by Werner von Siemens, who wanted to use it for underground cables. During three years of tests on behalf of the German government, it turned out that gutta-percha is destroyed by the natural aggressive substances of the earth and after a short time loses its insulating qualities in the underground water.

As an insulator for the core of the power cable, gutta-percha lasted relatively short, as the insulation became hard in the cold and soft under the influence of heat, it was expensive and therefore could not be made ideal (see — What are cable products).

Covering the cord with gutta-percha. Greenwich, 1865-66. Painting by R. C. Dudley

At that time the veins were laid in pipes of iron and lead and wrapped with strips of cotton, linen or jute. And in 1882, the idea appeared to use these materials for insulation. For this purpose, impregnating agents based on petroleum jelly with the addition of natural thickening resins have been created.

The gutta-percha press then used became a hydraulic lead press, by means of which the lead lining was applied directly to the core and there was no need to use iron pipes.

The sheath is protected from corrosion by bitumen-impregnated jute, which is wrapped around the cable. Two galvanized iron sheets impregnated with bitumen and laid overlapping were used as mechanical protection. For complete protection against corrosion, they were again covered with bitumen-impregnated jute.

Bitumen is one of the products that has left black marks on the hands of underground cable installers for many decades. Because it, known as "earth tar" or "rock tar," was mined as "natural asphalt," and today is mainly released during the vacuum distillation of oil, it was used as early as 2500 B.C. E. called "asphalt" by the inhabitants of Mesopotamia for the seals between the planks of the decks of their ships. It is also used as a precursor to linoleum to insulate floors from moisture penetration.

Balata, a product related to rubber and gutta-percha, is mined in Venezuela. Its properties are close to gutta-percha and it is used as an addition to it and to rubber. The bale contains more natural resins than rubber and gutta-percha and, unlike rubber, does not harden. It is used in large quantities as an impregnation in the production of power transmission belts and conveyor belts.

See also: