Piezoelectrics, piezoelectricity - physics of the phenomenon, types, properties and applications

Piezoelectrics Dielectrics are highlighted piezoelectric effect.

The phenomenon of piezoelectricity was discovered and studied in 1880-1881 by the famous French physicists Pierre and Paul-Jacques Curie.

For more than 40 years, piezoelectricity did not find practical application, remaining the property of physics laboratories. It was only during the First World War that the French scientist Paul Langevin used this phenomenon to generate ultrasonic vibrations in water from a quartz plate for the purpose of underwater location ("sounder").

After that, a number of physicists became interested in the study of the piezoelectric properties of quartz and some other crystals and their practical applications. Among their many works were several very important applications.

For example, in 1915 S.Butterworth showed that the quartz plate as a one-dimensional mechanical system, which is excited due to the interaction between an electric field and electric charges, can be represented as an equivalent electric circuit with capacitance, inductance and resistor connected in series.

Introducing a quartz plate as an oscillator circuit, Butterworth was the first to propose an equivalent circuit for a quartz resonator, which is the basis of all subsequent theoretical work. from quartz resonators.

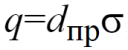

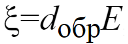

The piezoelectric effect is direct and inverse. The direct piezoelectric effect is characterized by the electrical polarization of the dielectric, which occurs due to the action of an external mechanical stress on it, while the charge induced on the surface of the dielectric is proportional to the applied mechanical stress:

With the reverse piezoelectric effect, the phenomenon manifests itself the other way around — the dielectric changes its dimensions under the action of an external electric field applied to it, while the magnitude of the mechanical deformation (relative deformation) will be proportional to the strength of the electric field applied to the sample:

The proportionality factor in both cases is the piezomodulus d. For the same piezoelectric, the piezomoduli for direct (dpr) and reverse (drev) piezoelectric effect are equal to each other. Thus, piezoelectrics are a type of reversible electromechanical transducers.

Longitudinal and transverse piezoelectric effect

The piezoelectric effect, depending on the type of sample, can be longitudinal or transverse.In the case of the longitudinal piezoelectric effect, charges in response to strain or strain in response to an external electric field are generated in the same direction as the initiating action. With the transverse piezoelectric effect, the appearance of charges or the direction of deformation will be perpendicular to the direction of the effect that causes them.

If an alternating electric field begins to act on a piezoelectric, then an alternating deformation with the same frequency will appear in it. If the piezoelectric effect is longitudinal, then the deformations will have the character of compression and tension in the direction of the applied electric field, and if it is transverse, then transverse waves will be observed.

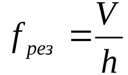

If the frequency of the applied alternating electric field is equal to the resonance frequency of the piezoelectric, then the amplitude of the mechanical deformation will be maximum. The resonance frequency of the sample can be determined by the formula (V is the speed of propagation of mechanical waves, h is the thickness of the sample):

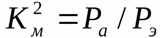

The most important characteristic of the piezoelectric material is the electromechanical coupling coefficient, which indicates the ratio between the force of mechanical vibrations Pa and the electrical power Pe spent on their excitation by impact on the sample. This coefficient usually takes a value in the range of 0.01 to 0.3.

Piezoelectrics are characterized by a crystal structure of a material with a covalent or ionic bond without a center of symmetry. Materials with low conductivity, in which there are negligible free charge carriers, are distinguished by high piezoelectric characteristics.Piezoelectrics include all ferroelectrics, as well as a wealth of known materials, including the crystalline modification of quartz.

Single crystal piezoelectrics

This class of piezoelectrics includes ionic ferroelectrics and crystalline quartz (beta-quartz SiO2).

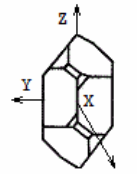

A single crystal of beta quartz has the shape of a hexagonal prism with two pyramids on the sides. Let us highlight a few crystallographic directions here. The Z axis passes through the apexes of the pyramids and is the optical axis of the crystal. If a plate is cut from such a crystal in a direction perpendicular to the given axis (Z), then the piezoelectric effect cannot be achieved.

Draw the X axes through the vertices of the hexagon, there are three such X axes. If you cut the plates perpendicular to the X axes, then we get a sample with the best piezoelectric effect. This is why the X-axes are called electric axes in quartz. All three Y axes drawn perpendicular to the sides of the quartz crystal are mechanical axes.

This type of quartz belongs to weak piezoelectrics, its electromechanical coupling coefficient is in the range of 0.05 to 0.1.

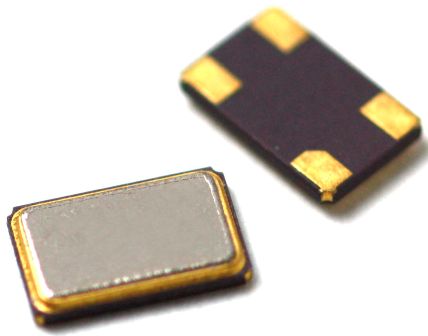

Crystalline quartz has had the greatest applicability due to its ability to maintain piezoelectric properties at temperatures up to 573 °C. Quartz piezoelectric resonators are nothing more than plane-parallel plates with electrodes attached to them. Such elements are distinguished by a pronounced natural resonance frequency.

Lithium niobite (LiNbO3) is a widely used piezoelectric material related to ion ferroelectrics (along with lithium tantalate LiTaO3 and bismuth germanate Bi12GeO20).Ionic ferroelectrics are pre-annealed in a strong electric field at a temperature below the Curie point to bring them into a single-domain state. Such materials have higher coefficients of electromechanical coupling (up to 0.3).

Cadmium sulfide CdS, zinc oxide ZnO, zinc sulfide ZnS, cadmium selenide CdSe, gallium arsenide GaAs, etc. They are examples of semiconductor-type compounds with an ionic-covalent bond. These are the so-called piezo semiconductors.

On the basis of these dipole ferroelectrics, ethylenediamine tartrate C6H14N8O8, tourmaline, single crystals of Rochelle salt, lithium sulfate Li2SO4H2O — piezoelectrics are also obtained.

Polycrystalline piezoelectrics

Ferroelectric ceramics belong to polycrystalline piezoelectrics. In order to impart piezoelectric properties to ferroelectric ceramics, such ceramics must be polarized for one hour in a strong electric field (with a strength of 2 to 4 MV / m) at a temperature of 100 to 150 ° C, so that after this exposure, polarization remains in it, which makes it possible to obtain a piezoelectric effect. Thus, robust piezoelectric ceramics with piezoelectric coupling coefficients of 0.2 to 0.4 are obtained.

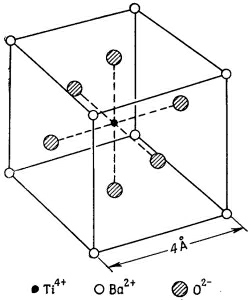

Piezoelectric elements of the required shape are made of piezoceramics in order to then obtain mechanical vibrations of the required nature (longitudinal, transverse, bending). The main representatives of industrial piezoceramics are made on the basis of barium titanate, calcium, lead, lead zirconate-titanate and barium lead niobate.

Polymer piezoelectrics

Polymer films (e.g. polyvinylidene fluoride) are stretched by 100-400%, then polarized in an electric field, and then electrodes are applied by metallization. Thus, film piezoelectric elements with an electromechanical coupling coefficient of the order of 0.16 are obtained.

Application of piezoelectrics

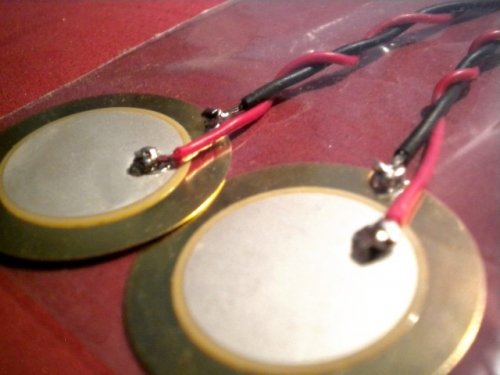

Separate and interconnected piezoelectric elements can be found in the form of ready-made radio engineering devices - piezoelectric transducers with electrodes attached to them.

Such devices, made of quartz, piezoelectric ceramics, or ionic piezoelectrics, are used to generate, transform, and filter electrical signals. A plane-parallel plate is cut from a quartz crystal, electrodes are attached - a resonator is obtained.

The frequency and Q-factor of the resonator depend on the angle to the crystallographic axes at which the plate is cut. Typically, in the radio frequency range up to 50 MHz, the Q factor of such resonators reaches 100,000. In addition, piezoelectric transducers are widely used as piezoelectric transformers with high input impedance, for a typically wide frequency range.

In terms of quality factor and frequency, quartz outperforms ion piezoelectrics, capable of operating at frequencies up to 1 GHz. The thinnest lithium tantalate plates are used as emitters and receivers of ultrasonic vibrations with a frequency of 0.02 to 1 GHz, in resonators, filters, delay lines of surface acoustic waves.

Thin films of piezoelectric semiconductors deposited on dielectric substrates are used in interdigital transducers (here variable electrodes are used to excite surface acoustic waves).

Low-frequency piezoelectric transducers are made on the basis of dipole ferroelectrics: miniature microphones, loudspeakers, pickups, sensors for pressure, deformation, vibration, acceleration, ultrasonic emitters.