Industrial control stations

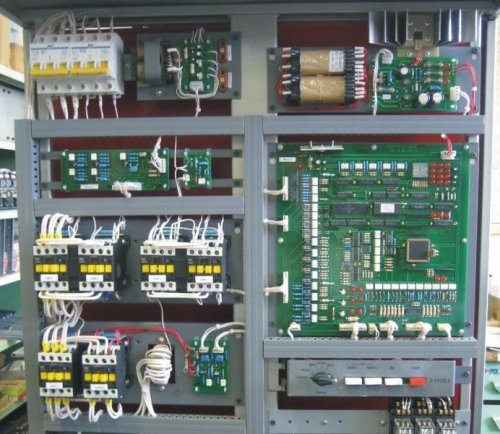

Control Station (CS) — a complete device with a set of necessary protective and switching devices (circuit breakers, fuses, thermal relays, contactors), relays, programmable controllers, frequency converters, measuring devices, clamps and other elements connected in accordance with the necessary electrical circuit, intended for remote control on a separate electrical receiver or electrical installation.

There are also auxiliary control stations containing a set of only a few protective devices, or a few relays, or measuring devices, allowing, in combination with other control stations, to employ complete power distribution and automatic control devices for production processes.

Control Panel (PU) — the station is like a block, but all devices and devices from which fit at least on a whole panel (two blocks with a height of 1000 mm). Unlike control blocks, control panels can have a width of 500 — 1100 mm with an interval of 100 mm.

The device consists of an insulating board without a frame, the panel consists of several insulating boards on a common metal frame.

Board for control stations (ShchSU) assembled in manufacturing plants from individual panels and control units. Thus, the concept of a control station shield includes (includes a group of panels or control units with all controllers installed on them, programmable controllers, signaling devices, meters, busbars, including busbars, wires, clamps for secondary circuits and attached boxes for resistance.

In machine rooms and other electrical rooms, open type control systems with unprotected live parts are usually installed. Installed in production rooms (closer to the production mechanisms), SCS are a set of IP31 or IP41 enclosures, each containing one or two SCS panels, a busbar compartment and connecting output lines.

In many large manufacturing plants, electrical equipment is centralized and, as a rule, operated remotely from a switchboard or control panel. On the control panel, in a certain order, determined by the sequence of technological operations, panels with the corresponding command-signal equipment, as well as with the necessary measuring devices, are mounted.

The switching equipment (circuit breakers, magnetic starters, contactors, breakers, fuses, relays) is installed on the control panel, which is mounted on the front side of the blocks and panels, the contact wires pass through the holes in the plates on the back side of the panels, where the wires are connected , suitable for the control panel, and the cables.

The number of adjacent panels that form the control panel can be different, depending on the production process and the number of drives connected to the control panel, and is determined by the design of the electrical part of the shop.

Pump station control stations

Most often, control stations are used for automation of various general industrial installations (pumps, fans, compressors, cranes, elevators, postal transport systems), for example in the automation of pumps and pumping stations, for controlling electric heating and melting furnaces, galvanic installations, electrostatic paints, etc.

For example, a pumping station is a link in the water supply system and is a rather complex electrical device that delivers water to consumers in the required volume with the required pressure. Automation, telemechanics and electronics systems are used in modern pumping stations.

By the nature of control, pumping stations are:

-

with manual control; semi-automatic, when the automated system is turned on by the operator from the control panel;

-

automatic, in which the station automation system is turned on and off by the primary signals received from the sensors (pressure, level, etc.);

-

with remote control, when turning on, turning off the units, the monitoring of their operation is carried out by the central control, located at a considerable distance from the pumping station.

Control panels in pumping and blowing stations are devices composed of vertical, flat, free-standing panels most conveniently located for viewing and performing the necessary remote switching. On the switchboard panels there are basic instruments, remote control equipment, emergency and warning signaling devices.

The measuring devices are located in the upper part of the panel, below there is a mnemonic diagram of the main connections, which must fully correspond to the single-line circuit diagram of the substation. Control switches for switching devices and devices for signaling the position of disconnectors are keyed into the mnemonic circuit. A mnemonic scheme for controlling units and valves, as well as a scheme for controlling their operation, are combined with control panels.

Examples of control stations

Variable frequency pump station control:

Automatic control station "Flow":

Passenger elevator control station NKU-MPPL (BPSh-1):

Requirements for control station premises

Rooms where SCS are installed are electrical and must fully meet PUE requirements. In addition, the premises of the SHSU must be equipped with supply and exhaust ventilation with air heaters for heating the outside air in winter.In the absence of ventilation with air heating, the heating of the ShchSU room in winter is carried out by register heaters, which exclude the penetration of water or steam into the room.

Floors in ShchSU premises can be made of any non-combustible, dust-free material. Floors behind the boards should be removable, made of corrugated steel. Movable floors can also be made on the front side of the control cabinet to facilitate the assembly and disassembly of cables laid in cable ducts. It is not allowed to install technological equipment in the premises of SHTSU, which during its operation can create strong vibrations.

The EMS room, longer than 7 m, must have two doors opening to the outside, permanently locked. Doors should be easily opened without a key from inside the room. The width of the doors should be at least 0.75, the height should be at least 1.9 m.

In the premises where the control system and technological equipment are installed, cleanliness must be maintained, since dirt and dust falling into the electrical equipment of the control circuits can cause malfunctions in the operation of the electrical equipment. Therefore, at least 2 times a month it is necessary to remove dust from electrical equipment and monitor the condition of contact connections.

Fire prevention measures

Control station panels are a critical part of the electrical installation, therefore it is necessary to provide special measures to prevent the possibility of fire.The causes of fires in electrical installations can be non-compliance with the rules for handling open flames, malfunctioning protection of electrical equipment against short circuits, excessive heating of wires due to poor contact or overload, smoking in prohibited places, etc. serve to prevent fires, locate and eliminate occurring sunburns.