Specific volume and surface resistance of solid dielectrics

Examination of a solid sample dielectric, it is possible to distinguish two fundamentally possible paths for the flow of electric current: over the surface of a given dielectric and through its volume. From this point of view, it is possible to evaluate the ability of the dielectric to conduct electric current in these directions, using the concepts of surface and volume resistance.

Bulk resistance It is the resistance that a dielectric exhibits when a direct current flows through its volume.

Surface resistance — This is the resistance that a dielectric exhibits when a direct current flows across its surface. Surface and bulk resistivity are determined experimentally.

The value of the specific volume resistivity of a dielectric is numerically equal to the resistance of a cube made of that dielectric, the edge of which is 1 meter long, provided that a direct current flows through its two opposite sides.

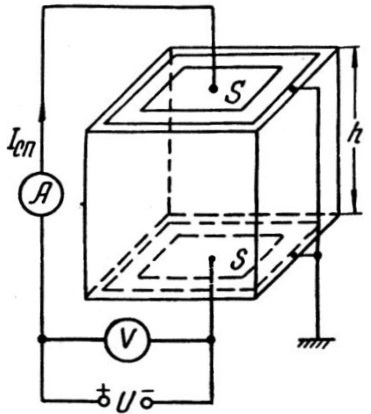

Wanting to measure the bulk resistance of a dielectric, the experimenter sticks metal electrodes to opposite sides of a cubic dielectric sample.

The area of the electrodes is taken equal to S and the thickness of the sample is taken h. In the experiment, the electrodes are installed inside protective metal rings, which are necessarily grounded in order to eliminate the influence of surface currents on the accuracy of the measurements.

When the electrodes and guard rings are installed in accordance with all appropriate experimental conditions, a constant voltage U is applied to the electrodes from a calibrated constant voltage source and held for 3 minutes, so that the polarization processes in the dielectric sample are certainly completed .

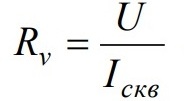

Then, without disconnecting the DC voltage source, measure the voltage and forward current using a voltmeter and a microammeter. The volume resistivity of the dielectric sample is then calculated using the following formula:

Volume resistance is measured in ohms.

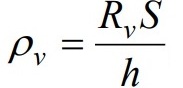

Since the area of the electrodes is known, it is equal to S, the thickness of the dielectric is also known, it is equal to h, and the volume resistance Rv has just been measured, you can now find the volume resistivity of the dielectric (measured in Ohm * m), using the following formula:

To find the surface resistivity of a dielectric, first find the surface resistivity of a specific sample. For this purpose, two metal electrodes of length l are glued to the sample at a distance d between them.

A constant voltage U from a constant voltage source is then applied to the bonded electrodes, which is maintained for 3 minutes so that the polarization processes in the sample are likely to end, and the voltage is measured with a voltmeter and the current with an ammeter.

Finally, the surface resistance in ohms is calculated using the formula:

Now, to find the specific surface resistance of a dielectric, it is necessary to proceed from the fact that it is numerically equal to the surface resistance of the square surface of a given material, if the current flows between the electrodes mounted on the sides of this square. Then the specific surface resistance will be equal to:

Surface resistance is measured in ohms.

The specific surface resistance of a dielectric is a characteristic of a dielectric material and depends on the chemical composition of the dielectric, its current temperature, humidity, and the voltage applied to its surface.

The dryness of the dielectric surface plays a huge role. The thinnest layer of water on the surface of the sample is sufficient to show appreciable conductivity, which will depend on the thickness of this layer.

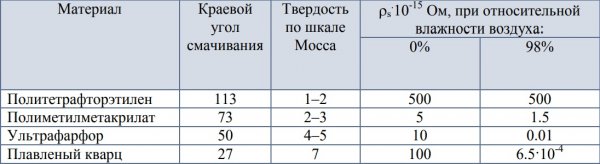

Surface conductivity is mainly due to the presence of impurities, defects and moisture on the surface of the dielectric. Porous and polar dielectrics are more susceptible to moisture than others. The specific surface resistance of such materials is related to the hardness value and the dielectric wetting contact angle.

Below is a table from which it is evident that harder dielectrics with a smaller contact angle have a lower specific surface resistivity in the wet state. From this point of view, dielectrics are divided into hydrophobic and hydrophilic.

Nonpolar dielectrics are hydrophobic and do not get wet with water when the surface is clean. For this reason, even if such a dielectric is placed in a humid environment, its surface resistance will practically not change.

Polar and most ionic dielectrics are hydrophilic and have wettability. If a hydrophilic dielectric is placed in a wet environment, its surface resistance will decrease. Various contaminants will easily adhere to the wet surface, which can also contribute to a reduction in surface resistance.

There are also intermediate dielectrics, these include weakly polar materials such as lavsan.

If wet insulation is heated, its surface resistance may begin to rise as the temperature rises. When the insulation is dry, the resistance may decrease. Low temperatures contribute to an increase in the surface resistance of the dielectric in the dried state by 6-7 orders of magnitude, compared to the same material, only wet.

To increase the surface resistance of the dielectric, they resort to various technological methods. For example, the sample can be washed in a solvent or in boiling distilled water, depending on the type of dielectric, or heated to a sufficiently high temperature, covered with a moisture-resistant varnish, glaze, placed in a protective shell, case, etc. .