Methods of using neodymium magnets in technology and industry

Neodymium magnet. Who hasn't heard of him today? But the history of this invention dates back to 1983, when the Chinese Academy of Sciences, the American General Motors and the Japanese Sumitomo Corporation developed this unique chemical compound independently of each other.

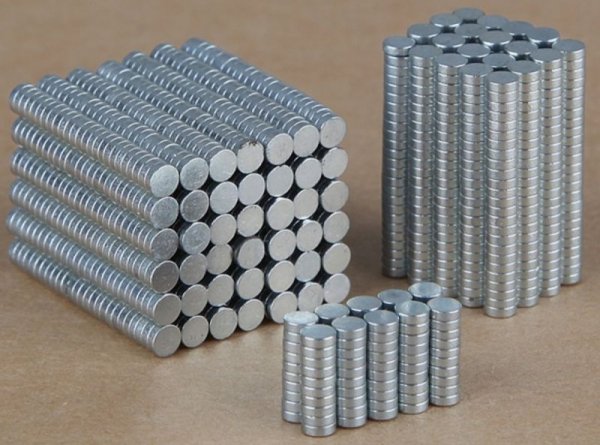

The powder, consisting of a mixture of three metals, is baked in a special oven under pressure at a temperature of 1200 ° C, as a result of which a finished product is obtained. An alloy of neodymium, iron and boron, known today as a neodymium magnet in the form in which we know it - covered with a shiny nickel layer, has long gained popularity in various fields of technology, industry, electronics and just in everyday life.

As a result, permanent powerful neodymium magnets with high resistance to demagnetization are used today for a variety of purposes, they are available in many sizes and in a wide variety of shapes. And their most important advantage is that these small magnets have a colossal magnetic induction.

It is for this reason that we come across neodymium magnets almost at every turn, hardly noticing their ubiquitous presence in one form or another. Now we will tell you how wide the use of neodymium magnets is in modern industry, technology and in other areas of human life.

Metallurgy

It is known that a huge amount of small metal shavings always accumulate on the floor near metal cutting machines in metalworking shops, which can injure workers and simply take up a lot of space, while it is always better to clean the shavings immediately. This is where neodymium magnets come to the rescue.

The problem is solved simply: the magnet is placed in a bag, which is then passed over the place of accumulation of magnetic shavings. All the shavings immediately stick to the bag, after which the worker must turn the bag inside out and turn off the magnet. And now all the shavings are already collected - they are in the bag.

In the production of parts and assemblies, powerful neodymium magnets are also often used, where they can act as clamps or vices. In addition, magnets allow metal objects to be sorted and lifted to significant heights. With the help of a powerful lifting magnet, you can lift and move loads weighing up to 1 ton!

Electricity and electrical engineering

Today, you will not surprise anyone with the fact that many relays and sensors, rotors of motors and generators, even in such grandiose structures as industrial hydroelectric power plants and wind turbines, use neodymium magnets in their blocks instead of the obsolete field coils. Here, large currents through the rotor windings are no longer needed, and the spark brushes can be left for a long time.

Brushless synchronous generators owe their durability to powerful neodymium magnets, such as multi-turn brushless DC motorswhose rotors also have neodymium magnets on their poles. These motors are easy to operate and do not require special maintenance. By the way, it has long been known that the power generator directly depends on the strength of the magnets used on its rotor.

Electronics

Neodymium magnets are often used in the manufacture of headphones and speakers, especially speakers, in the speakers of radios, mobile phones, smartphones — to obtain a higher maximum allowable volume from them.

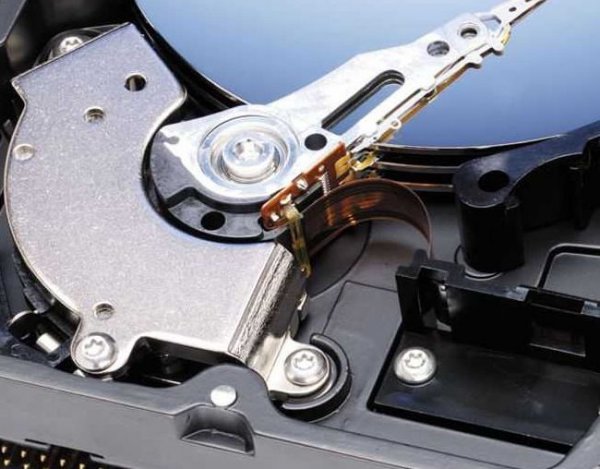

Arc-shaped neodymium magnets continue to be indispensable in the computer hard drive industry.

Cubic neodymium magnets are also used in laser focusing systems in digital devices.

Food industry and agriculture

In the food industry and agriculture, neodymium magnets are used to remove foreign metal objects from large volumes of grain, cereals and other food products. Livestock feed, a variety of bulk foodstuffs (basically all small non-magnetic parts) owe their purity to such devices as magnetic separators.

The drum, equipped with neodymium magnets, rotates near a conveyor along which a certain crude bulk product moves. Magnetic impurities are immediately removed and remain on the separator drum, which is periodically cleaned and enters the next cycle. The process is fully automated.

In principle, magnetic separation as material separation is widely used today not only in food, but also in metallurgical, chemical, glass and other industries.

The same principle will allow you to find a metal object in everyday life using a neodymium magnet. It often happens that a needle falls on the floor and how to find it? But you can simply hold a powerful neodymium magnet above the floor. In a similar way, curious tourists find various objects in the coastal sand of the seas, and summer residents take out the iron objects that fell there from the wells.

The oil and gas industry

Electric motors of submersible pumps and their hermetically sealed connectors, deparaffinization devices, magnetic barriers and traps, elements of diagnostic complexes — work thanks to neodymium magnets. They clean liquid media of metal impurities and prevent the formation of scale. Oil filter manufacturers use these magnets to remove metal filings from petroleum products.

Textile industry, souvenirs and everyday life

Needless to say about the textile industry, where various bag fasteners, cosmetic cases, covers and even clothes are all clips with neodymium magnets hidden inside, which is much more convenient than buttons.

In general, neodymium magnets as staples can replace paper clips, clips, and even glue in many applications.Many souvenirs, such as fridge magnets, brochures and banners, gift wrap, folders, etc., would not be as convenient and accessible without neodymium magnets.

Pay attention to your daily routine. How often does a neodymium magnet help connect parts without using glue? This can be, for example, several sheets of paper that need to be temporarily fixed on a magnetic board. And if it is a matter of gluing different surfaces, then strong pressing of these surfaces to each other can be ensured again with the help of a pair of strong neodymium magnets.

By the way, using a powerful magnet, you can hang a hammer or ax on the wall in your home workshop without the need to build a special holder or hanger.

Construction and installation of furniture

In construction, neodymium magnets have found useful applications in the assembly of formwork, and in the production of cabinet furniture - just as a reliable vice. Speaking of furniture, let's not forget about magnetic door locks.

Medicine

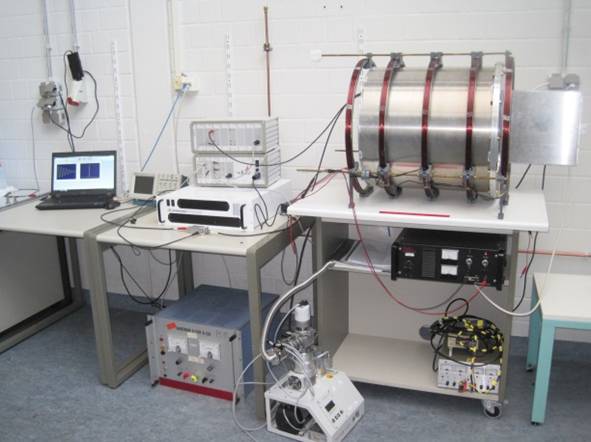

Neodymium magnets have revolutionized health and the modern medical technology industry. Magnetic resonance imaging machines (MRI machines) require strong magnetic field sources to operate. Very powerful permanent magnetsspecially made for these devices (requires induction from 1 to 9 T), are suitable for some models of this equipment.

It is believed that magnetized water has a healing effect on the human body, is able to normalize blood pressure and relieve the symptoms of arthritis. Although this is a rather controversial position.

Nuclear industry

In the production of nuclear fuel, magnetic centrifuges are used to separate isotopes. Moving in a strong magnetic field, charged particles of different masses will move along different trajectories, and therefore ions of different masses will accumulate in different traps installed at different places on the centrifuge.

Automotive

Locking devices, micromotors, sensors, etc. are found in every modern car. And how can we do without neodymium magnets here?

By the way, cleaning the oil of small metal particles as a result of the friction of the working parts of the internal combustion engine against each other can also be done by simply attaching a high-temperature neodymium magnet to the drain plug of the crankcase. Periodically, this magnet will collect enough "dirt" that it will simply need to be cleaned from time to time.

Well, probably everyone already knows about the method of magnetically attaching plates and badges to the metal body of a car. Only a sufficiently strong magnet (namely, only neodymium) is able to ensure the retention of such objects on the body of a car moving at high speed, so that it does not fly off onto the road.