Types, structure and characteristics of thermoregulators (thermostats)

Thermostats are electromechanical or electronic devices designed to maintain a predetermined temperature of the environment or the body. These devices are widely used in heating equipment and cooling systems, being in demand both in industry and agriculture, and in everyday life, where they can often be found in heating, air conditioning, etc.

The principle of operation of the thermostat is the timely inclusion or exclusion of a source of heat or cold (heating element, fan, air conditioner) in order to provide suitable conditions, that is, to maintain the correct temperature (for example: air in an apartment, water in a tank, surface on any equipment).

The thermostat receives real-time temperature data due to its availability temperature sensor, which can be remote or built into the thermostat housing.

Accordingly, if the thermal sensor is installed correctly, that is, in the right place, where external influences on it are excluded, then the thermostat will work correctly — the equipment will turn on and off at the specified time.

If the sensor is located, for example, near an electric heater and it is necessary to adjust the air temperature, then the whole system will not work properly, because it will be turned off too early and turned on too late.

Thermostats are industrial and domestic, wall mounted and DIN rail, for indoor or outdoor installation, wired and wireless, mechanical and electronic, they are available as wired products in various shapes and sizes.

These devices for various purposes can be designed to work in one or another limited temperature range, starting usually from a lower value of -60 ° C, ending with 1000 ° C or more, depending on the capabilities and type of temperature sensor.

There are single-channel and multi-channel thermostats. Multi-channel devices, unlike single-channel ones, can work simultaneously with several sensors, which is in particular demand, especially in agriculture.

Mechanical and electromechanical temperature regulators

The simplest thermostat is mechanical. These are the ones that are usually used to control heating and artificial cooling in small rooms, ventilation in rural greenhouses. The reaction temperature is set by changing the setpoint.

Regulators of this type do not have an electronic control circuit, and their work is realized due to the properties of some metals to react mechanically to temperature changes.

Bimetallic plate the initially closing (opening) contact, when heated (cooled) to a certain temperature, bends, which leads to the opening (closing) of the power circuit of the device, for example, a heating element (or fan).

In this way, the device controlled by the regulator is turned on and off literally by mechanically closing and opening the circuit. Thermostats on steamers, irons, electric kettles, electric heaters have a similar device.

Regulators of this type are cheap, reliable, insensitive to surges and very easy to install. The disadvantage of these solutions is the presence of a significant error.

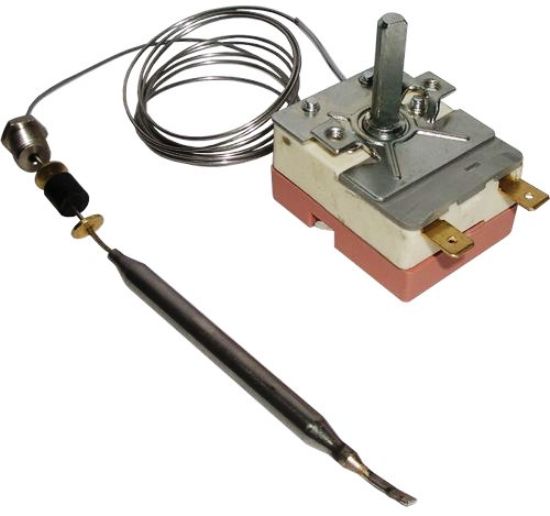

An electromechanical capillary tube thermostat is often useful in boilers and boilers. Here a tube filled with gas is placed in a container of water. When the water is heated, it transfers heat to the tube, the gas in it expands and presses the actuating membrane, causing the contacts to open.

Electronic temperature regulators

Digital and analog room thermostats are designed to maintain a certain air temperature in a certain room, for example, equipped with a "warm floor" system or electric heating. Often the sensor is built directly into the device housing. Temperature controllers for industrial use with a built-in sensor usually have increased housing protection.

There are thermostats whose sensors are mounted in the wall or in the floor, while the device itself is above and mounted on the wall.

It is especially worth emphasizing the regulators with an infrared sensor, which allows you to monitor and adjust the air temperature in rooms with high humidity, such as a sauna, shower or bathroom.

The regulator is installed directly in a dry room, and the sensor is installed in a wet room. There are also waterproof versions of this type of regulator; they can be installed directly in a wet room.

Digital electronic devices, unlike analog ones, have higher accuracy and are less sensitive to interference, but are more expensive than mechanical ones. However, they are also quite common, especially in heating (underfloor heating) and air conditioning systems.

The sensor is remote, and the device itself is equipped with a display and buttons (or touch panel). The required temperature is set using the controller, and switching is done with an electronic switch. Temperature data is transmitted from the sensor — to the controller that controls the switching.

Thermostats for more complex systems also take into account the air temperature outside the window and allow you to automate heating, air conditioning and ventilation systems, regulate their work more optimally, which has a positive effect on both monetary costs and the well-being of people in the room , where this system is working.

For more complex control use programmable thermostats… These can be both single-channel thermostats and thermostats with several sensors.

Programmable models have more customization options, including the option to set operating hours and temperature parameters for different areas of the facility. These solutions are more efficient, highly accurate and save energy.

There are models of programmable controllers that can be easily integrated into the "smart home" system, making it possible to manage the entire heating system from one place or simply from a smartphone.