Brushes and brush holders of direct current electric machines: purpose, material, types and device

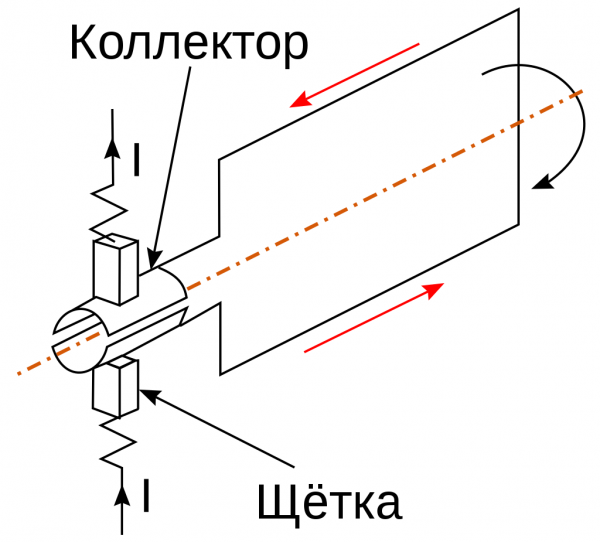

In electric motors and generators, it is often necessary to establish an electrical connection between the stationary and rotating parts of the device.

In the case of a stator (i.e. stationary) main winding of an electrical machine, it is easy to arrange branches from it to connect an external stationary electrical system, but in the case of a rotor (i.e. rotating) main winding, it it becomes necessary to arrange a sliding electrical contact, because otherwise the rotor winding is not available.

The electrical sliding contact can be implemented in two ways: either as a ring sliding contact or as a collector sliding contact. In both cases, the operation of an electric machine requires special devices - brushes.

In the first electric machines, the brushes were a package assembled from copper plates or thin wires, from which they got their name.

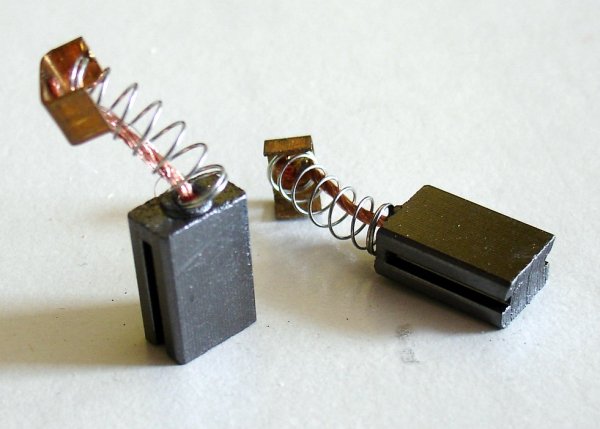

The brushes of modern machines are cubes pressed from coal, graphite or copper powders and therefore do not live up to their name, which, however, remained behind them.

Copper, iron and bronze brushes, which did the job very well in the first DC machines in the late 19th century, turned out to be not very good materials in terms of friction. They wear out quickly and in new machine designs they are replaced by coal and graphite.

Currently for DC machines used almost exclusively carbon brushes with an admixture of graphite, bearing, depending on the percentage of graphite and the way the brushes are made, the names of carbon-graphite, graphite or electrograph. Only for low-voltage machines, up to 30 V, metal-carbon brushes are used, which give a lower voltage drop in the contact (transition) layer on the collector.

Carbon brushes are made of pure graphite, retort carbon and carbon black in various proportions. Coal is a self-lubricating material that does not damage the surface it rubs on and does not wear out quickly.

Graphite brushes are made of pure natural graphite. The graphite is crushed into a fine powder, which is then pressed under very high pressure into rods of the desired size. Coal and graphite are excellent conductors of electricity.

Electrographite brushes They are essentially carbon brushes but exposed to high temperatures in an electric furnace and thus converted to graphite. These brushes have very good grinding properties.

Carbon brushes made of coal and copper crushed into a fine powder, sometimes with the addition of another crushed metal (most often tin).

The production of these brushes is carried out in such a way that the brush has the best possible conductivity in the axial direction, in which the working current of the machine passes, and poor conductivity (high electrical resistance) in the transverse direction, in which the additional currents of the included sections are closed during commutation.

Electric machine brushes are standardized. They are characterized by hardness, transient voltage drop in the contact and permissible current density.

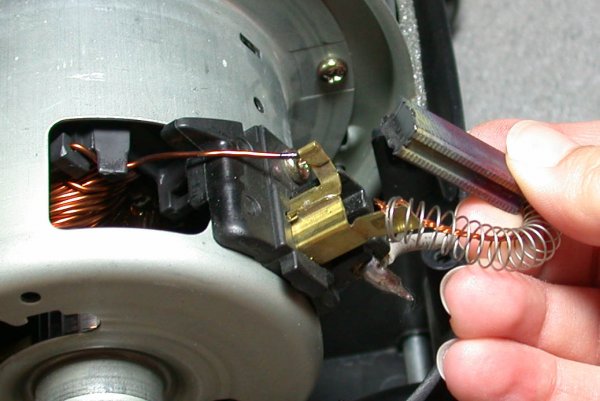

This energy transmission technology, which is more than a hundred years old, is still widely used today. Carbon brushes can still be found in many electric motors. Starting with small motors in toys, electric kitchen appliances, electric windows, shavers, washing machines, hair dryers, vacuum cleaners or power tools (electric drills, angle grinders, routers, circular saws, etc.),

Brushes are also used in large direct current machines in electric locomotives, submarines and power station generators, as well as in wind turbines. Accordingly, the geometric and electrical characteristics of carbon brushes are different.

The number of zones (forming the cylindrical surface of the collector) of the assembly of brushes on the collector is usually equal to the number of poles of the machine. The number of brushes in each zone depends on the value of the current and the current density under the brush permissible for a given type of brush, but less than two brushes per zone can only be found in very small machines, since with one brush per zone it is difficult to ensure the reliability of the brush contact.

Brushes that stay in the same zone are called a zone brush set, and the set of all zone sets of a given machine is called a complete brush set.

The end surface of the brushes on the side opposite to contact with the collector is usually copper-plated, sometimes tinned. At a small current drawn by the brush, sufficiently satisfactory conditions for current drain are provided by the contact surface of the brush with the brush holder and the compression spring.

The large brushes are fitted with caps made of sheet copper, tightly fitted thereon, and with wires attached to them, made of soft flexible cables of suitable sections, with tips for fastening under a screw to a brush holder or to a part intended for draining brush current. The rope brush cap is called a brush arm.

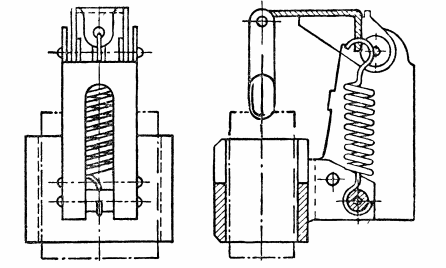

The brushes are held in a fixed position relative to the collector brush holders, whose design is very diverse.

If the electric machine is designed for both directions of rotation, then radial brush holders are used, which ensure the location of the brush along the radius of the collector. On machines with one specific direction of rotation, brush holders are often used with some inclination of the brush to the radius.

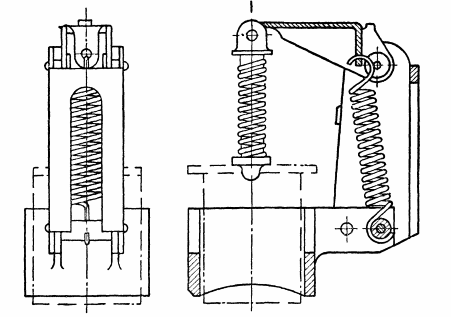

Brush holder for low and medium power DC machines

Large brush holder for DC machine

Single zone brush holders are attached to round or square brush fingers or to brush clamps… Brush fingers or clamps from different brush areas are reinforced brush supports or brush sleepersfrom which they must be reliably isolated.

In turn, the even sleepers are attached either to the bearings, or to the end shields, or to the yoke, or, finally, independently to the base plate of the machine (for long collectors).

Important conditions that the brush support or brush crosshead must meet are the absolute absence of vibration, accessibility for checking and adjusting the brushes, easy removal of the individual brush holders for repairs and the ability to simultaneously rotate the entire brush system for precise mounting in the correct commutation position while maintaining full concentricity of brush holders and collector.

Brushes, brush holders, fingers (or clamps) and a traverse (or support) make up the so-called current collector of a DC machine. It also includes connections between zone brush sets of the same polarity.

To drain the current, the brush fingers and clamps of the zones of the same name (that is, of the same polarity, positive or negative) are electrically connected to each other with an insulated wire of the corresponding section.

In this way, two complete or partial collecting rings are obtained, which are then connected by flexible cables of suitable cross-section to the external terminals of the machine. The latter are fixed on a special clamping board either to the yoke or to the main plate of the machine. The terminal board, covered with a protective cover, forms a terminal box.

Proper brush application and selection, combined with proper maintenance, results in increased machine performance and reduced downtime costs.

Since the friction caused by rotating the device causes abrasive wear, the brushes must be replaced periodically.For that reason, brushless motors.