Devices for switching control circuits: buttons, switches and switches

Switching control circuits is a more common operation than switching power circuits. The operation of any machine or installation begins with the selection of the operating mode, control method, connection of the necessary drives, auxiliary devices (lubrication, cooling, power supply, etc.), as well as monitoring, signaling and recording systems. For all these operations, use switches and switches of different designs located on panels, pillars and control panels. This is a single and multi-circuit device with two or more positions... Switching of control circuits for turning on and off relay-contactor equipment control buttons is carried out.

Switching control circuits is a more common operation than switching power circuits. The operation of any machine or installation begins with the selection of the operating mode, control method, connection of the necessary drives, auxiliary devices (lubrication, cooling, power supply, etc.), as well as monitoring, signaling and recording systems. For all these operations, use switches and switches of different designs located on panels, pillars and control panels. This is a single and multi-circuit device with two or more positions... Switching of control circuits for turning on and off relay-contactor equipment control buttons is carried out.

Packet switches used for switching control circuits are essentially the same devices as for power circuits, but with smaller overall dimensions.

Packet switching designs intended for control circuits make it possible to obtain a variety of connection schemes (up to 220 options) with the number of switched circuits up to 24 (12 packets) and the number of fixed positions from 2 to 8 (after 45, 60 or 90 °). In addition, there are switches with self-return to the original position, that is, without fixing the switched position, which may be necessary for a number of circuits. The peculiarity of these switches is a locking (key) device that excludes uncontrolled switching. Structurally, these keys have the same type of plastic sections (by the number of packages) with contact nodes assembled on a common shaft and a common locking mechanism. The movable contacts of each section are moved by cams mounted on a common shaft.

The most common control keys are devices of the PKU2 and PKUZ series.

The rated (continuous) current of PKU2 series switches is 6 A (at 380 V AC and 220 V DC), and for PKUZ switches — 10 A (at 500 V AC and 220 V DC). The switching capacity of these switches under load is determined by the values of the operating voltages and inductance of the circuit (cosfi for AC and time constant for DC).

A feature of the design of the switches of the PKUZ series is the presence of several versions with a built-in lock, a movable key — a handle and a device that locks the handle of the switch with a padlock.

Universal control switches series UP5100, UP5300 and other similar types are also produced by a set of types of contact sections, the commutation of which is carried out by cams mounted on a common shaft.The versatility of these switches is achieved due to the large number of connection schemes (up to 300) with the number of switched circuits from 2 to 48 and positions 2-10 (fixed and stationary at an angle of 45, 60, 90 and 180 °). The rated current of these switches is 12 A at a voltage of 500 V AC or 440 V DC, that is, in terms of basic electrical parameters, these switches are superior to other similar devices.

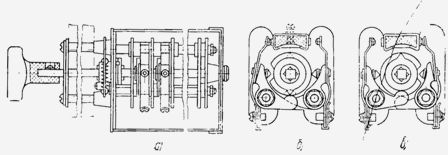

In fig. 1 shows a UP5300 type universal switch for 12 sections. Universal switches are open, enclosed, waterproof and explosion-proof. The considered switches (package, cam and universal) switch switching circuits with relatively high currents (up to 12 A), and therefore they are close in dimensions to power circuit switching devices.

Figure 1. Universal switch UP5300: a — design, b — position with left closed contacts, c — position with right closed contacts.

The complexity of modern control systems leads to the use of a large number of different switches located on panels and control panels, therefore the overall dimensions of the devices become a determining factor in their selection. But widely used in schemes automation elements requires the use of such switches, the contacts of which would ensure reliable passage of low currents (mils or microamps) at reduced voltage values (24, 12 V and lower).

The switches considered above, as a rule, do not have such properties, since their contacts have a significant transient resistance. These requirements are met by the so-called Low-current equipment for radio electronics with bimetallic or silver contacts that ensure reliable passage of low currents at low voltage.

An intermediate position between batch control switches for general industrial design and radio electronic equipment is occupied by switches of the PU, PE and switch series.

These switches are usually designed for flange mounting on control panel panels (ring in front of panel and nut behind panel). They have two or three positions, closing up to four circuits with different combinations of contacts.

These switches are usually designed for flange mounting on control panel panels (ring in front of panel and nut behind panel). They have two or three positions, closing up to four circuits with different combinations of contacts.

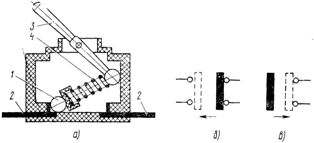

In fig. 2 shows a switch device and the most common schemes for its use as a two-position switch (Fig. 2, b) or a switch (Fig. 2, c).

The bridge contact, made in the form of a conductive roller 1, closes one of the two pairs of fixed contacts 2. The switching of the switch contacts is carried out by action on the lever 3, and acceleration of operation (momentary action) is provided by a cylindrical spring 4. Rated current of switches 1 and 2 A at a voltage of 220 B, their mass does not exceed 30 g.

Switches of the PU and PE series — devices with a rotary mechanism leading to two or three positions. Switches with a removable key handle are of interest, since their use excludes the possibility of uncontrolled operation. The rated current of the switches is 5A at 220VAC and 1A at 110VDC. Such switches, as a rule, block the supply of voltage to the control circuit, lock input devices, change control modes and methods, etc. In this case, it is possible to lock the switch both in the off position and in its other positions.

Switches of the PU and PE series — devices with a rotary mechanism leading to two or three positions. Switches with a removable key handle are of interest, since their use excludes the possibility of uncontrolled operation. The rated current of the switches is 5A at 220VAC and 1A at 110VDC. Such switches, as a rule, block the supply of voltage to the control circuit, lock input devices, change control modes and methods, etc. In this case, it is possible to lock the switch both in the off position and in its other positions.

Automatic and programmed machine control systems require very complex switches that require multi-position and multi-circuit switches (with the number of circuits and positions up to 20 and sometimes more). Since devices switches of radio electronics automation devices and instruments are used... Structurally, such devices are made in the form of two, four or more fixed sections, mounted on boards and movable contacts, fixed on a common shaft and fixed with a special spring ball in advance certain positions.

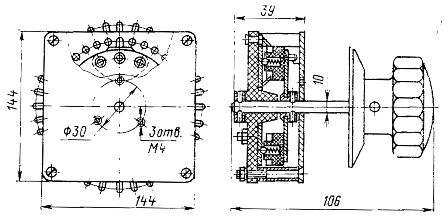

In fig. 3 shows the most common slide switches PP series, single panel design for 35 circuits. Open type switches are designed for flush mounting behind the control panel. Similar brush switches, but in a version with a closed panel, have from 1 to 4 sections and the number of contacts in each section from 4 to 24. Multi-circuit brush switches provide reliable switching of alternating current circuits with a voltage of up to 380 V and a DC voltage of up to 220 V at load current up to 1 A.

In fig. 3 shows the most common slide switches PP series, single panel design for 35 circuits. Open type switches are designed for flush mounting behind the control panel. Similar brush switches, but in a version with a closed panel, have from 1 to 4 sections and the number of contacts in each section from 4 to 24. Multi-circuit brush switches provide reliable switching of alternating current circuits with a voltage of up to 380 V and a DC voltage of up to 220 V at load current up to 1 A.

Sliding chain switch, PP series

Radio switches (of the PGK and PGG series) have sometimes been used in machine automation schemes. These switches have from 2 to 11 positions with the number of sections (biscuits) from 1 to 4. Nowadays, more sophisticated and convenient switches and buttons are widely used instead. Such switches are a switchable panel of buttons (or keys) mounted on a common frame and equipped with a locking mechanism that can be independent for each button or locked.

Each button switches its contacts (from 2 to 8 in various combinations) and can be self-setting or with alternating on and off fixed positions. Some versions of switches are equipped with a special button to return (reset) the included buttons to their original position. In this case, it is possible to turn on the position of several buttons at the same time.

A feature of these switches is the on/off position of each button (or keys). The required control mode or program is set by such switches through a set of on and off positions of the corresponding buttons (keys). The position of the buttons also acts as a pointer. At the same time, light signaling devices (lamps or LEDs) installed in the housing of the switch block are also used.

A feature of these switches is the on/off position of each button (or keys). The required control mode or program is set by such switches through a set of on and off positions of the corresponding buttons (keys). The position of the buttons also acts as a pointer. At the same time, light signaling devices (lamps or LEDs) installed in the housing of the switch block are also used.

The closed design in combination with the use of high-quality materials (bimetals, silver alloys, etc.) for the contacts provides an opportunity to obtain low contact resistance, which is very important when using these devices in low-voltage and low-current circuits for automation and electronics .

Control buttons - these are devices whose movable contacts move and are activated when the push button is pressed. A set of buttons mounted on a common panel (or block) is station with buttons… All control buttons used in automation schemes are distinguished by the number and type of contacts (from 1 to 4 make and break), the shape of the pusher (cylindrical, rectangular and mushroom-shaped), the inscriptions and colors of the pushers, as well as by the method of protection against environmental influences (open, closed, sealed, explosion-proof, etc.).

Control buttons - these are devices whose movable contacts move and are activated when the push button is pressed. A set of buttons mounted on a common panel (or block) is station with buttons… All control buttons used in automation schemes are distinguished by the number and type of contacts (from 1 to 4 make and break), the shape of the pusher (cylindrical, rectangular and mushroom-shaped), the inscriptions and colors of the pushers, as well as by the method of protection against environmental influences (open, closed, sealed, explosion-proof, etc.).

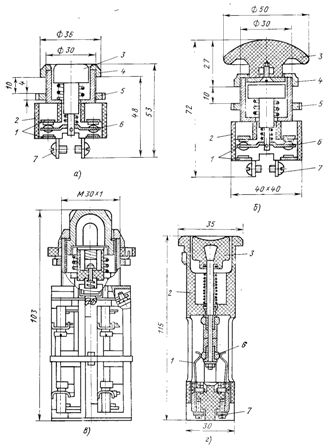

Control button: a-double chain button, type KU2, b-double chain mushroom button, type KUA1, c-double-block button with signal lamp, d-small size button with spring contacts, type K20

Regardless of the design and overall dimensions of the buttons, they all have fixed contacts 1 and movable contacts 6, moved by a pusher 3. The external circuit is connected to the button by screw clamps 7. The body 2 of the button is fixed to the control panel with nuts 4 and 5 .

KU and KE series general industrial control buttons have different designs. These buttons are used to make button stations containing from 1 to 12 buttons of different designs, assembled on a common panel or in one housing with appropriate protection.