Electrical insulating varnishes

Electrical insulating varnishes are colloidal solutions of various film-forming substances in specially selected organic solvents. Film-forming substances are those which, as a result of the evaporation of solvents and the processes of solidification (polymerization), are able to form a solid film.

Electrical insulating varnishes are colloidal solutions of various film-forming substances in specially selected organic solvents. Film-forming substances are those which, as a result of the evaporation of solvents and the processes of solidification (polymerization), are able to form a solid film.

Film-forming substances include resins (natural and synthetic), vegetable drying oils, cellulose ethers, etc. Volatile (volatile) liquids are used as film-forming solvents: benzene, toluene, xylene, alcohols, acetone, turpentine, etc.

To create an electrical insulation varnish meeting a number of requirements, select several film-forming substances that make up the base of the varnish.

To create an electrical insulation varnish meeting a number of requirements, select several film-forming substances that make up the base of the varnish.

For complete dissolution of the varnish base and uniform drying of the varnish, it is sometimes necessary to apply several solvents. To dilute thickened varnishes, thinners are introduced into them, which differ from solvents in their lower volatility. Moreover, they can only dissolve the varnish base in a solvent mixture. Gasoline, varnish kerosene, turpentine and some other liquids are used as thinners.

The composition of the insulating varnish may also include plasticizers and driers. Plasticizers — substances that give elasticity to the varnish film. They include castor oil, linseed oil, fatty acids and other fatty liquids. Drivers are liquid or solid substances introduced into some varnishes (oil, etc.) to accelerate their drying.

When drying the varnish layer applied to any surface containing organic substances, the solvents evaporate (evaporate) and the film-forming substances in, as a result of polymerization processes, they form a solid varnish film. This film can be flexible (elastic) or inflexible and brittle depending on the properties of the film-forming substances that make up the lacquer base.

According to their purpose, electrical insulating varnishes are divided: for impregnation, coating and glue.

According to their purpose, electrical insulating varnishes are divided: for impregnation, coating and glue.

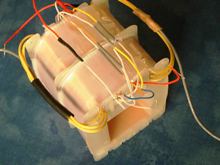

Impregnating varnishes are used to impregnate windings in electrical machines and devices for cementing (connecting) turns of the winding to each other, as well as to eliminate porosity in winding insulation.

The impregnating varnish, penetrating into the pores of the insulating insulation, displaces the air from there and, after hardening, makes the winding resistant to moisture. This increases the dielectric strength of the winding insulation and its coefficient of thermal conductivity. One of the main characteristics of impregnating varnishes is their impregnating ability.

Coating varnishes are used to create moisture-resistant or oil-resistant varnish coatings on the surface of already impregnated coils.Coating varnishes also include enamels used to enamel winding wires, as well as varnishes used to insulate sheets of electrical steel in magnetic circuits.

Adhesive varnishes are used for gluing different electrical insulating materials: mica sheets (in the production of layered mica insulation), ceramics, plastics, etc. The main requirement for adhesive varnishes is that these varnishes have good adhesion (adhesion) and form a strong seam.

It should be noted that in practice it happens that the same varnish is used as impregnation and coating, or as coating and glue.

All varnishes are divided into two groups according to the drying method: air drying varnishes (cold) and oven drying varnishes (hot).

I have air-drying insulating varnishes, the film cures at room temperature. Air drying varnishes include shellac, ether cellulose and some others.

I have electric insulating varnishes drying in an oven, hardening of the film is possible only at temperatures significantly higher than room temperature (from 100OC and above). Oven-dried varnishes use thermoreactive film-forming substances (glyphthalic, resol and other resins), whose hardening is due to polymerization processes that require elevated temperatures. Baking lacquers usually have better mechanical and electrical properties.

I have electric insulating varnishes drying in an oven, hardening of the film is possible only at temperatures significantly higher than room temperature (from 100OC and above). Oven-dried varnishes use thermoreactive film-forming substances (glyphthalic, resol and other resins), whose hardening is due to polymerization processes that require elevated temperatures. Baking lacquers usually have better mechanical and electrical properties.

According to the base of the varnish, the electrical insulating varnishes are divided into resin, oil, bituminous oil and ether cellulose.

Resin varnishes are solutions of natural or synthetic resins in organic solvents. Resin varnishes include Shellac, Glyphtal, Bakelite, Silicon Silicon, etc.Resin varnishes can be thermoplastic (polyvinyl acetal, polyvinyl chloride, etc.) and thermoset (glyphthalic, bakelite, etc.).

Oil varnishes are solutions of vegetable (drying and semi-drying) oils in organic solvents. Dryer oils include wolfberry and linseed oils.

Tung oil is extracted from the nuts of the tree, dries quickly, forming an elastic moisture-resistant film. Linseed oil is obtained from linseed. Linseed oil, boiled to a certain density, serves as a base for oil varnishes.

Desiccants are usually introduced into oil varnishes - substances that accelerate the drying of varnishes. Oil varnish films are thermoreactive substances, that is, they do not soften when heated.

The field of application of oil varnishes in electrical engineering is very limited compared to resins. Oil varnishes are used for impregnation of electrical insulating varnishes, enamelling of winding wires and as topcoats resistant to moisture.

Oil-bitumen varnishes are solutions of oil-bitumen mixtures in organic solvents (turpentine, toluene, xylene, etc.). Petroleum and natural bitumen (asphalt) are used for this. Of the vegetable oils, linseed oil is mainly used.

The films of these varnishes are black. They have good electrical insulation properties, elasticity and water resistance. Oil-bituminous varnish films are thermoplastic and easily dissolve in mineral oils and in a number of solvents, which is their disadvantage. Oil-bituminous varnishes are widely used as impregnating varnishes for windings of electrical machines.

The films of these varnishes are black. They have good electrical insulation properties, elasticity and water resistance. Oil-bituminous varnish films are thermoplastic and easily dissolve in mineral oils and in a number of solvents, which is their disadvantage. Oil-bituminous varnishes are widely used as impregnating varnishes for windings of electrical machines.

Ether cellulose varnishes are solutions of cellulose ethers (nitrocellulose, cellulose acetate, etc.) in a mixture of solvents (amyl acetate, acetone, alcohols, etc.). The films of these varnishes are transparent, have a characteristic gloss and are resistant to mineral oils, gasoline and ozone.

Ether -cellulose varnishes are mainly used for varnishing cotton braids of wires with rubber insulation — to protect the rubber from the action of gasoline, mineral oils and ozone. These varnishes do not adhere well to metals. The use of ether-cellulose varnishes is facilitated by the fact that they are air-dried varnishes, but their field of application in electrical engineering is relatively small.