Programmable intelligent relays

Programmable intelligent relays are a type of PLC (programmable logic controllers). The use of intelligent relays makes it possible to significantly simplify the control schemes of electrical equipment and increase their reliability.

Programmable intelligent relays are a type of PLC (programmable logic controllers). The use of intelligent relays makes it possible to significantly simplify the control schemes of electrical equipment and increase their reliability.

Programming for smart relays is done using front panel buttons and a small, usually one or two line LCD indicator. Although there are more complex constructions and in these cases the programs must be written on a personal computer using specialized programming languages for ladder logic LD, FBD and some others.

Interfaces such as RS-232, RS-485 or Industrial Ethernet are used to load (flash) ready programs into the microcontroller's memory, which also allow communication with higher-level ACS. Some models of programmable smart relays allow you to build communication capabilities using special expansion modules.

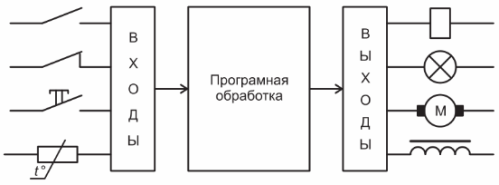

Working principle of PLC

The difference between smart relays and full-fledged PLCs is that they have a small amount of RAM and program memory, and this leads to the impossibility of at least some complex mathematical calculations. In addition, the number of input-output channels, both digital and analog, in smart relays is also small, therefore the scope of their application is quite limited. First of all, this is automation of individual units, control of lighting systems, some devices in the system for housing and communal services, local loops of various automation systems, household appliances.

A characteristic of such devices is their local use for small systems, and the program for them is created mainly in the language of functional block diagrams (FBD) or in the language of relay logic (LD). These languages comply with the international standard IEC 61131-3. The software of such relays has a convenient and friendly interface and allows you to develop programs in a short time, check the syntax and correctness of the created program, and also has the ability to debug the program in real time, which clearly gives an idea of how the controller will behave in this or other situation.

Design of programmable intelligent relays most often monobloc, — one small case contains all nodes. As a rule, these are a low-power power supply unit, a microcontroller, input and output information channels, terminals for connecting executive devices. The housings of such devices are small and allow installation in electrical cabinets on a DIN bus that meets modern standards. However, the power supply can also be a separate device.

Overseas programmable intelligent relays

Programmable relays are now produced by many companies, mostly foreign. As an example, we can recall the company Schneider Electric, which was founded in 1936 in France. Its headquarters are located in Rueil-Malmaison Cedex. The company manufactures its products under the Telemecanique, Merlin Gerin, Modicon brands.

Schneider Electric products are very diverse: from conventional circuit breakersto complex devices such as frequency converters, signaling and control devices, soft starters, control relays, sensors and programmable relays and controllers. As an example of a smart relay, consider Zelio Logic Programmable Relays.

Schneider Electric Zelio Logic programmable relays allow the implementation of small control systems, the number of inputs / outputs is within 10 ... 40 channels. In the case of dimensions 124.6 * 90 * 59 mm, it is possible to place up to 26 input / output channels. At the same time, the supply voltage of the device is in a very wide range: 24VAC, 100 … 240VAC, 12VDC, 24VDC, which facilitates the integration of the relay in any constructions.

For example, the SR2B201FU series relay has 12 discrete inputs and 8 relay outputs, is designed for AC voltage 100-240V, and includes a clock, display and a set of buttons. The external view of the intelligent relay in a monoblock design is shown in the figure.

Two specialized languages FBD or LADDER can be used to program the Zelio Logic relay. The device is available in both monobloc and modular design. The last option allows combining modules to expand the system as a whole.

The scope of the Zelio Logic relay is wide enough and provides control of compressors or pumps, counting of finished products or components of automatic lines, control of escalators, lighting and electronic displays. It can be used in security systems as access control devices.

In addition to the aforementioned Schneider Electric, a number of foreign companies are engaged in the production of programmable relays: OMRON, Control Techniques, SIEMENS, Mitsubishi Electric, Danfoss, ABB, Moeller, Braun, Allen Bradley, Autonics, Array Electronic, Eaton.

The most popular programmable smart relays: Siemens LOGO!, Omron ZEN, Schneider Electric Zelo Logic, Easy Moeller, Mitsubishi Alpha XL, Delta Electronics DVP-PM, Eton dasy500, dungeon800, xLogic ELC, Owen Logo, Oni Logo, PRO-relay , ARIES PR110, ARIES PR200.

Array FAB Series Electronic Programmable Logic Controllers from Taiwan

For industrial and household use, the company produces intelligent relays of the second generation of the FAB series. These devices are quite easy to operate and easy to learn and program. FAB relays are programmed using the FDB programming language, which is primarily intended for automation engineers. With its help, it is possible to create a rather complex system, at the same time effective and economical.

The FDB programming language is the language of the blocks that appear on the display during program entry. Functional blocks are simply arranged and combined in a certain sequence, both sequentially and in parallel, which allows you to visually create quite complex algorithms.It does not require knowledge of programming languages. For someone who has ever dealt with the maintenance of digital technologies, for example, CNC machines, this language will not cause difficulties.

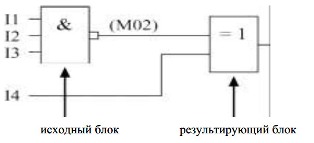

In total, the language has 20 blocks that perform different functions. First of all, these are logic operations that outwardly look like pictures from a digital microcircuit reference book. The figure shows a fragment of two blocks.

In addition to logic operations, the block set also contains counters, timers, time delays, on and off timestamps, and more.

The programming environment is shipped with the devices and is also available for download from the manufacturer's website. FAB series intelligent relays replace a large number of switching devices: relays, tachometers, counters, timers, etc. while at a fairly low price. A programmable smart relay can replace an entire cabinet assembled with a conventional one electromechanical relays… At the same time, the reliability of the circuit as a whole increases, the number of discrete elements decreases, the dimensions decrease and the power consumption decreases.

The fields of application of FAB intelligent relays are quite wide. These are smart home systems; automatic opening of doors, barriers and gates; lighting control both internal and external; ventilation control and temperature control in enterprises and in residential premises, in greenhouses and greenhouses. And management of the water supply system, management of production lines and individual machines, application in alarm systems, in emergency warning systems and many others.

Brief technical characteristics of FAB intelligent relays

The relay is equipped with an LCD display with 4 lines of 10 characters, has a built-in calendar and a real-time clock. Remote control over telephone lines and the ability to transmit voice messages are possible. The delivery kit includes a free simple SCADA program that allows communication with a computer at a sufficiently large distance, which enables remote monitoring and configuration. In case of using the RS — 485 interface, 255 FAB relays can be connected to one computer. This connection allows you to create more functional systems than using single FAB relays.

The outputs of the device have a high load capacity: relay outputs — 10A, transistor outputs — 2A.

Although the program memory is small — only 64K, the program can contain 127 function blocks, 127 counters, 127 RTC (real time) intervals, 127 timers, which allows you to create quite complex function programs. Program input is done either using buttons and an LCD display, or using a computer. To protect the program from unauthorized access, password protection is possible.

Internal programmable relays

In Russia, the manufacturer of programmable relays deals with the Voronezh company «Oven» and the Nizhny Novgorod «KontraAvt». The company «Aries» releases its relays under the name of Aries PLC ***.

Voronezh CJSC "Ekoresurs" produces a series of controllers "Basic", which includes several modifications of the device. The magazines "Industrial Automation", "Instrumental Engineering and Automation Tools" and "Industrial Automation Systems and Controllers" have a whole series of articles on the use of Bazis series controllers.

Some companies are engaged in the distribution and sale of imported brands in Russia. For example, Intechnics, a commercial partner of the English company Invertek Drives, which produces such popular variable frequency drives, supplies to Russia and programmable intelligent relays, which are so necessary for the creation of automation systems.

Examples of relay applications

Escalator control. Ensuring continuous operation only on weekdays from 8:00 AM to 6:00 PM. · From 18:00 to 20:00 the escalator is only activated when a person appears.

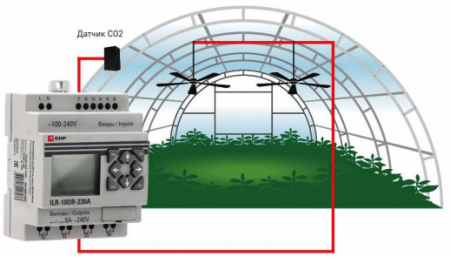

Ventilation control. Turn on ventilation every 30 minutes for 10 minutes. Turn on ventilation for 10 minutes when the set CO2 level is exceeded.

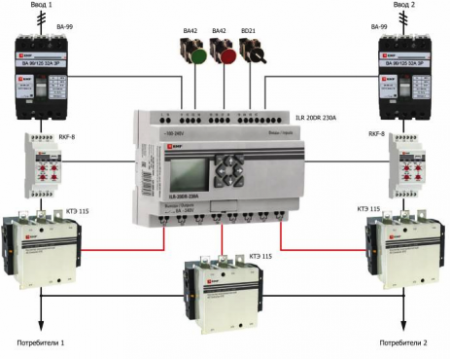

Manage automatic reserve transfer. Automatic reserve input with 2 or more inputs. Separation. On / off users. Turn on/off DGS and other sources.

An example of developing a relay program

Suppose it is necessary to develop a mixer control program for a ZelioLogic programmable intelligent relay in FBD language, the task is as follows.

Liquid No. 1 is fed into a vertical vessel 7 m high until a level of 2.8 m is reached. Then the supply of the first liquid is stopped and liquid No. 2 is fed until the total level of 4.2 m is reached. Then the supply of the second liquid is stopped and the motor of the agitator is turned on, which runs for 30 minutes. After the time has elapsed, the motor is turned off and the slurry drain valve is opened.

To solve the problem, it is necessary first of all to convert the level values into data understandable by the controller, i.e.the value at the 2.8 m level, based on the capacity of the on-board ADC, will correspond to the controller input value equal to 102, and at the 4.2 m level, the value 153.

Also, based on the problem conditions, the controller outputs must interact with three shut-off valves—fluid supply #1, fluid supply #2, suspension drain, and one mixer motor. When solving this problem, it is recommended to connect a button to the input of the controller, which will ensure the start of the entire system.

The development of the program is carried out using a computer on which the ZelioSoft 2 software is installed.

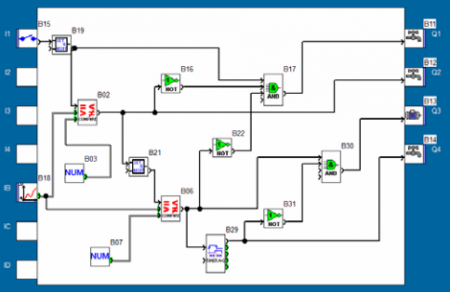

The graphical programming language for FBD controllers uses different function blocks. Each block is part of a complete program that provides a specific functional relationship between input and output variables.

The connection of the blocks leads to the unification of individual modules into a single control program, which, in accordance with the values of the input variables of the sensors connected to the inputs of the programmable relay, generates control signals for the actuators connected to the outputs.

Thus, the programming process is reduced to the selection of various functional blocks, placing them in the editing window and connecting them in a certain sequence, which provides a solution to a specific problem with the automated control of a process or object.

To solve the problem, the necessary blocks were selected and connected and their parameters were set, which ensure the given logic of operation.

A graphical representation of the program in the ZelioSoft2 environment using FBD that implements the solution to this problem is shown in the figure.

Fixed FBD language issue

Checking the correctness of the configuration of individual blocks and their connections is carried out in simulation mode. After making sure that the program is working correctly, it is transferred from the instrument computer to the memory of the programmable relay.

Exit

Intelligent programmable relays, despite their shortcomings, can perform a number of tasks in industrial and non-industrial areas where there is no need to use programmable logic controllers (PLCs).

They are also significantly cheaper than PLCs, allowing savings in the process of upgrading or automating a manual or automatic process. To program an intelligent programmable relay, the user does not need to have programming skills, a set of typical programs can be used. Smart relays are easy to program.