What is induction motor soft start for?

Of all the types of motors, induction motors are the most widely used in industry and continue to replace more and more DC motors.

Of all the types of motors, induction motors are the most widely used in industry and continue to replace more and more DC motors.

Asynchronous motors became widespread due to the following qualities: low cost of the engine, simplicity of design, reliability, high efficiency. Until now, asynchronous motors have been inferior to direct current motors only in cases where smooth speed control is required (planing machines, straightening machines, adjustable main drives of roll mills, etc.), in electric transport and in high power drives with periodic work (reversing mills). Industrial introduction adjustable frequency converters will allow asynchronous motors to be used even more widely.

The disadvantages of asynchronous motors are:

1) The quadratic dependence of the torque on the voltage, with a drop in the network voltage, the initial and critical torque are significantly reduced,

2) Danger of overheating the stator, especially when the mains voltage rises, and the rotor when the voltage drops,

3) A small air gap, somewhat reducing the reliability of the engine,

4) Large starting currents of asynchronous motors… When starting an induction motor with a squirrel-cage rotor, the stator current is 5-10 times higher than the rated one. Such high currents in the stator are unacceptable in terms of dynamic forces in the windings and heating of the windings. Transient modes with large inrush currents can occur in asynchronous motors, not only when the motor is connected to the grid, but also when it is reversed and decelerated.

So why should you limit the inrush current in the stator windings of a squirrel-cage induction motor?

The need to limit motor current is dictated by electrical and mechanical reasons. The reasons for the electrical nature of the current limiting of the motors can be the following:

1) Reduction of power surges in the network. In some cases, for large motors, it is necessary to limit the inrush current to that permitted by the power system.

2) Reduction of electrodynamic forces in motor windings.

Reduction of network surge currents is usually required when starting large induction motors with a cage if they are fed from a relatively low power supply system. In addition, for large motors, machine manufacturers do not allow direct starting due to excessively large electrodynamic forces at the faces of the stator and rotor windings.

The reasons for the mechanical nature of limiting the torque of motors can be very diverse, for example, to prevent breakage or rapid wear of gears, slipping of belts from rollers, slipping of wheels of moving trolleys, large accelerations or decelerations that are unacceptable for equipment or people in different vehicles etc. Sometimes it is necessary to reduce the starting torque of the engines, even a small one, to soften the shocks of the gears and ensure smooth acceleration.

In all cases where the operating conditions do not require forced acceleration or deceleration, it is advisable to calculate the modes for the minimum inrush current, and therefore the torque, while maintaining the transmission of the mechanism and the motor.

Engine soft starter

To limit the current, starting reactors, resistors and autotransformers are used, as well as modern electronic devices - soft starters (motor soft starters).

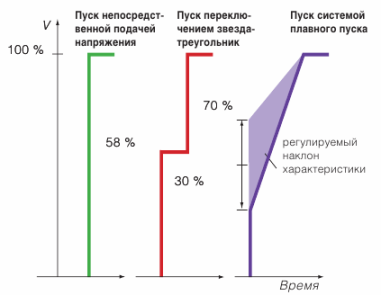

Motor voltage

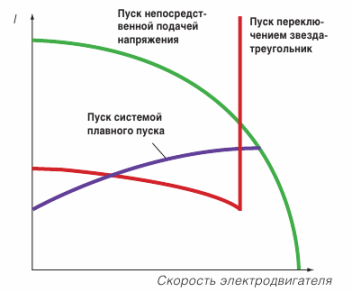

Motor current

It is necessary to pay attention to the fact that limiting the current and torque using soft starters of motors is achieved due to the complexity of the control circuit and the increase in the cost of the installation, and therefore it should be used only where it is justified.

Continuing this thread: How to choose the right starter (soft starter)