Selection of electric motors for auxiliary drives of metal cutting machines

Auxiliary drives on machine tools (quick drives for calipers, head pads, cross arms, etc.) typically operate in a short-time load mode. The mode of operation of the electric drive of such duration, in which the temperature of all devices included in the electric drive does not reach a stationary value during operation and decreases to the ambient temperature during a pause, is called short-term.

Auxiliary drives on machine tools (quick drives for calipers, head pads, cross arms, etc.) typically operate in a short-time load mode. The mode of operation of the electric drive of such duration, in which the temperature of all devices included in the electric drive does not reach a stationary value during operation and decreases to the ambient temperature during a pause, is called short-term.

The operating time of auxiliary drives on metal cutting machines is usually short; it does not exceed 5 — 15 s, and only for heavy machines it reaches 1 — 1.5 minutes. During this time (t < 0.1T) with an overload within the permissible limits, the electric motor does not have time to heat up even to normal overheating. The rated power of the electric motor in this case is determined by the overload conditions.

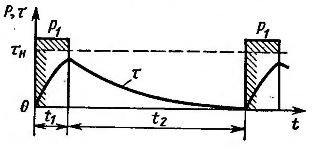

Rice. 1. Load curve for short-term operation

The moment of resistance Mc during the operation of auxiliary drives is created mainly by frictional forces, and therefore these drives, unlike the drives of the main motion, require a significant starting torque.

Consumed power to overcome frictional forces when moving a horizontally moving machine element:

where Ftp — force of friction, N; v — velocity, m/s; G — the gravity (weight) of the unit being moved, N; μ — coefficient of friction of movement.

Motor shaft power P = Ptr /η,

where η — c. P. D. Transmission, typically η = 0.1 — 0.2.

The heating of the electric motor during operation in the considered mode is insignificant. Therefore, it is recommended to use its permissible overload.

Rated power Pn = Ptr /(λη),

where λ — coefficient of permissible overload.

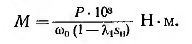

Roughly, it can be considered that the characteristic of the engine in its working part is clear. Then the angular velocity of the motor in overload operation

ωλ = ωО (1 — λсн),

where, ωО = (πнО)/30- synchronous angular speed of the electric motor.

Using the formula Pn = Ptr /(λη), find the overload torque of the motor

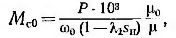

The moment of resistance at the beginning of starting the engine is greater than during its operation. This moment

where μО — coefficient of friction at rest.

The procedure for selecting electric motors of the auxiliary drives of the machine

First, using the formula Pn = Ptr /(λη) an electric motor is selected from the catalog, for which the starting torque Mnach is then determined. Calculate the moment Mso by the formula and compare with the moment Mnach.If 0.85 Mnig> Mso, then the selected motor is suitable for the auxiliary drive.

Drives for turning and lifting machine units are calculated in a similar way, only in the latter case the main load is often created by the force of gravity (weight) of the moved unit.

It is of particular importance to choose the optimal speed to quickly approach the tool to the workpiece. When approaching the tool, the high-speed movement is replaced by a slow movement at cutting speed. This speed change occurs when the tool is some distance from the part, otherwise the tool will hit the part at high speed and break.

The transition from one speed to another takes some time. During this time, electrical equipment is activated and the movement continues at high speed. The response time of the equipment changes due to voltage fluctuations and the influence of other random factors.

The optimal speed is provided by the appropriate selection of gears in the kinematic chain. A further reduction in time is possible by a gradual or smooth automatic reduction of the speed of the final section of the road, which makes it possible to adopt a higher initial speed.