How galvanometers work and work

A galvanometer is an electrical measuring instrument with a non-graduated scale that has a high sensitivity to current or voltage. Galvanometers are widely used as zero indicators and also for measuring small currents, voltages and quantities of electricity if the galvanometer constant is known.

A galvanometer is an electrical measuring instrument with a non-graduated scale that has a high sensitivity to current or voltage. Galvanometers are widely used as zero indicators and also for measuring small currents, voltages and quantities of electricity if the galvanometer constant is known.

In addition to magnetoelectric, there are other types of galvanometers, such as electrostatic, called electrometers. However, their use is very limited.

The main requirement for galvanometers is high sensitivity, which is mainly achieved by reducing the counter moment and using a light pointer with a long beam length.

They are distinguished by design:

(a) portable galvanometers (with built-in scale) in which both indicating and light indicators are used;

b) mirror galvanometers, with a separate scale, requiring stationary level adjustment.

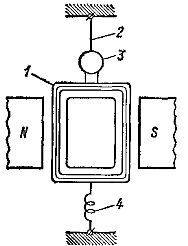

In portable galvanometers, the movable part is mounted on wires, and in mirror galvanometers - on a suspension (Fig. 1).In the second case, the current supply to the winding of the frame 1 is carried out by means of a suspension 2 and a thread without torque 4. To measure the angle of rotation of the frame, a mirror 3 is used, on which light is illuminated, a beam from a special illuminator is focused.

Rice. 1. The device of the galvanometer on the suspension

The constant of a mirror galvanometer of this design depends on the distance between the mirror and the scale. It was agreed to express for a distance of 1 m, for example: CAz = 1.2x 10-6-6 A. A • m / mm. For portable galvanometers in the passport, indicate the price of the scale division, for example: 1 division = 0.5 x 10

The most sensitive modern mirror galvanometers have a constant value of up to 10-11 A-m / mm. For portable galvanometers, the constant is about 10-8 — 10-9 A / div.

The standard for galvanometers allows a constant (or division of the scale) to deviate from what is indicated in the passport by ± 10%.

An important feature of the galvanometer is the constancy of the zero position of the pointer, which is understood as the non-return of the pointer to the zero mark when it smoothly moves from the end mark of the scale. According to this parameter, galvanometers are divided into constant discharges. The conventional indication of the discharge of permanence at the zero position of the pointer of the galvanometer, consisting of the numerical designation of the permanence discharge enclosed in a diamond, is applied to the scale of the galvanometer when marking.

Rice. 2. Galvanometer

Many galvanometers provide a magnetic shunt. By adjusting the position of the shunt using the handle brought out, it is possible to change the value of the magnetic induction in the working gap.This changes the constant as well as a number of other parameters of the galvanometer. As required by the standard, the magnetic shunt must change the direct current at least 3 times. In the passport of the galvanometer and in its marking, the values of the constant are indicated in two end positions of the shunt - fully inserted and fully withdrawn.

The galvanometer must have a corrector that moves the pointer to one side or the other of the zero mark during circular rotation. Galvanometers with a movable suspension part must be equipped with a lock (a device for mechanically fixing the movable part), which is engaged, for example, when the device is worn.

Due to their high sensitivity, galvanometers must be protected from interference. So, galvanometers are protected from mechanical shocks by mounting them on main walls or special bases, from leakage currents — by electrostatic shielding, etc.

The nature of the movement of the moving part of the galvanometer when the measured value changes depends on its damping, which is determined by the resistance of the external circuit. For convenience when working with a galvanometer, this resistance is chosen close to the so-called external critical resistance RKindicated in the passport of the galvanometer. If the galvanometer is closed to an external critical resistance, then the arrow smoothly and in a minimum time approaches the equilibrium position, does not cross it and does not fluctuate around it.

A ballistic galvanometer allows you to measure small amounts of electricity (current pulse) flowing over short periods of time — fractions of a second. Thus, the ballistic galvanometer is designed for pulse measurements.The ballistic galvanometer theory shows that if we accept the assumption that the moving part begins to move after the end of the current pulse in the coil of the moving frame, then the amount of electricity flowing in the circuit B, proportional to the first maximum deflection of the pointer α1m, i.e. is. Q = SatNS α1m, where Cb is the ballistic constant of the galvanometer, expressed in pendants per division.

It should be noted that Sb does not remain unchanged for a given galvanometer, but depends on the resistance of the external circuit, which usually requires its determination in the process of measurements experimentally. The above assumption is fulfilled the more accurately, the greater the moment of inertia of the moving part of the galvanometer and, therefore, the longer the period of free oscillations To. For ballistic galvanometers T0 is tens of seconds (for conventional galvanometers — units of seconds). This is achieved by increasing the moment of inertia of the moving part of the galvanometer with the help of an additional part in the form of a disk.