High polymer dielectrics

Highly polymeric materials (highly polymeric) consist of molecules of large size, which include tens and hundreds of thousands of molecules of the starting substances — monomers.

Highly polymeric materials (highly polymeric) consist of molecules of large size, which include tens and hundreds of thousands of molecules of the starting substances — monomers.

Distinguish between natural high polymers (natural rubber, amber, etc.) and synthetic (synthetic rubber, polyethylene, polystyrene, polyvinyl chloride, etc.).

A characteristic feature of high polymers is their good electrical insulating properties. Synthetic high polymers are formed during polymerization (polymerization materials) or polycondensation (polycondensation materials) reactions. The latter have lower electrical insulation properties, because in the process of polycondensation they are contaminated with by-products (acids, water, etc.).

High polymer materials consisting of linearly oriented molecules (rubbers, rubbers, etc.) are flexible, and high polymers consisting of spatially developed molecules (bakelites, glyphtals, etc.) are not flexible. Linear high polymers, as a rule, are thermoplastic substances, that is, they soften when heated.This property is used in the production of flexible products from thermoplastic high polymers: films, threads, as well as in the production of cast parts (coils, boards, etc.).

High polymer materials consisting of linearly oriented molecules (rubbers, rubbers, etc.) are flexible, and high polymers consisting of spatially developed molecules (bakelites, glyphtals, etc.) are not flexible. Linear high polymers, as a rule, are thermoplastic substances, that is, they soften when heated.This property is used in the production of flexible products from thermoplastic high polymers: films, threads, as well as in the production of cast parts (coils, boards, etc.).

High polymer materials consisting of spatially developed molecules are, as a rule, thermoreactive substances. After heat treatment, these materials pass into an insoluble and insoluble state (bakelite, glyphtal, etc.).

Polystyrene They are produced in two types: block (plates, sheets, granules) and emulsion — in the form of powder, from which various electrically insulating parts are pressed or molded under pressure. Polystyrene is used to produce polystyrene films and strips with a thickness of 20 to 100 microns. The softening point of polystyrene is 95–125 ° C. At a temperature of 300 ° C, polystyrene passes into the original liquid, that is, it depolymerizes.

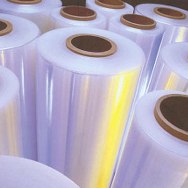

Polyethylene produced in the form of granules, blocks, as well as films and strips. Low pressure polyethylene (LP) has higher density, increased mechanical strength and heat resistance, but is less elastic than high pressure polyethylene (HP). Polyethylenes dissolve only in heated non-polar solvents (benzene, toluene, etc.).

Polyethylene produced in the form of granules, blocks, as well as films and strips. Low pressure polyethylene (LP) has higher density, increased mechanical strength and heat resistance, but is less elastic than high pressure polyethylene (HP). Polyethylenes dissolve only in heated non-polar solvents (benzene, toluene, etc.).

Fluoroplast-3 at a temperature of 315 ° C and above, it decomposes with the release of monomer — gas. Melting point 200-220 ° C. No cold flow.

I have fluoroplast-4 the decomposition process begins at 400 ° C; its highest working temperature is 250 ° C; yield is observed at 20 °C (cold yield) at stresses above 35 kg/cm2.

All fluoroplasts have low corona resistance, i.e. low corona resistance.

Escapon (or thermoebonite) — a material obtained as a result of polymerization of synthetic rubber at 250-300 ° C without the introduction of sulfur.The material is characterized by low dielectric losses and high electrical strength.

Polycaprolactam (nylon) has a melting point of 210-220 ° C. The working temperature of nylon should not exceed 100 ° C.

Polyurethane has a melting point of 175-180 ° C.

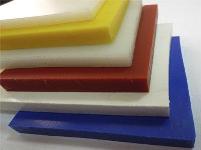

Viniplast — an elastic material based on PVC (without plasticizers), made in the form of sheets and plates with a thickness of 0.3 to 20 mm, as well as in the form of pipes, rods and angles. Viniplast is a thermoplastic material, weldable well, subject to of mechanical processing, very resistant to chemically active environments (acids, bases, ozone), solvents and oils. In aromatic and chlorinated hydrocarbons (benzene, toluene, chlorobenzene, dichloroethane, etc.) vinyl plastic swells and partially dissolves. Viniplast is a non-combustible material. Decomposition temperature 150-160 ° C.

Viniplast — an elastic material based on PVC (without plasticizers), made in the form of sheets and plates with a thickness of 0.3 to 20 mm, as well as in the form of pipes, rods and angles. Viniplast is a thermoplastic material, weldable well, subject to of mechanical processing, very resistant to chemically active environments (acids, bases, ozone), solvents and oils. In aromatic and chlorinated hydrocarbons (benzene, toluene, chlorobenzene, dichloroethane, etc.) vinyl plastic swells and partially dissolves. Viniplast is a non-combustible material. Decomposition temperature 150-160 ° C.

PVC compounds — flexible non-combustible materials based on polyvinyl chloride with plasticizers. They are resistant to mineral oils, gasoline and other solvents, except for aromatic (benzene, toluene, etc.) and chlorinated (dichloroethane, chlorobenzene, etc.) hydrocarbons. The highest operating temperatures of PVC compounds are in the range of 160-180 ° C (plastic compound, resistant to light). At temperatures of 160-220 ° C, plastic compounds begin to decompose.

Polymethyl methacrylate They are produced in the form of sheets (organic CO glass) and powder, from which various electrical insulating parts are obtained, resistant to mineral oils, gasoline and bases (by hot pressing or pressure casting). At temperatures of 80-120 ° C, polymethyl methacrylate products soften, and at 250-300 ° C, the material decomposes (depolymerizes).When exposed to an electric arc, the material gives off gases that contribute to its extinguishment; therefore, polymethyl methacrylate is used in pipe restraints. Polymethyl methacrylate is stamped at 80-120 °C.