Electric throttle - principle of operation and examples of use

An inductor used to suppress interference, to smooth current waves, to store energy in the magnetic field of a coil or core, to isolate parts of a circuit from each other at high frequency, is called a choke or reactor (from German drosseln — to limit, wedge).

An inductor used to suppress interference, to smooth current waves, to store energy in the magnetic field of a coil or core, to isolate parts of a circuit from each other at high frequency, is called a choke or reactor (from German drosseln — to limit, wedge).

Therefore, the main purpose of a choke in an electrical circuit is to hold on itself a current in a certain frequency range or to accumulate energy for a certain period of time in a magnetic field.

Physically, the current in the coil cannot change immediately, it takes a finite time, — directly follows this position from Lenz's rule.

If the current through the coil can be changed instantaneously, then an infinite voltage will appear across the coil. The self-inductance of the coil, when the current changes, creates a voltage by itself — EMF of self-induction… In this way, the choke slows down the current.

If it is necessary to suppress the variable component of the current in the circuit (and noise or vibration is only an example of a variable component), then a choke is installed in such a circuit — inductor, which has a significant inductive resistance for the current at the interference frequency. Ripples in the network will be greatly reduced if a choke is installed on the path. Similarly, signals of different frequencies operating in the circuit can be separated or isolated from each other.

In radio engineering, in electrical engineering, in microwave technology, high-frequency currents of units from hertz to gigahertz are used. Low frequencies within 20 kHz refer to audio frequencies, followed by the ultrasonic range — up to 100 kHz and finally the HF and microwave range — above 100 kHz, units, tens and hundreds of MHz.

So it's the throttle self induction coil, used as a large inductive resistance for certain alternating currents.

In case the choke has to have a large inductive resistance to low frequency currents, it has to have a large inductance and in this case it is made with a steel core. A high-frequency choke (representing a high resistance to high-frequency currents) is usually made without a core.

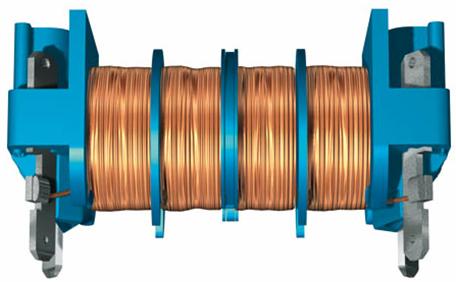

Low-frequency choke It looks like an iron transformer, with the only difference that it has only one coil on it. The winding is wound on a steel core of a transformer whose plates are insulated to reduce eddy currents.

Such a coil has a high inductance (more than 1 N), it has significant resistance to any change in current in the electrical circuit where it is installed: if the current starts to decrease sharply, the coil supports it, if the current starts to increase sharply, the coil will limit, it will not accumulate sharply.

One of the widest areas of application of chokes is high-frequency circuits... Multi-layer or single-layer coils are wound on ferrite or steel cores or are used without ferromagnetic cores at all - only a plastic frame or only wire. If the circuit operates on waves of medium and long range , then a sectional winding is often possible.

A ferromagnetic core choke is smaller than a coreless choke of the same inductance. For operation at high frequencies, ferrite or magneto-dielectric cores are used, which have a low internal capacitance. Such chokes can operate over a fairly wide frequency range.

As you know, the main parameter of the choke is the inductance, like any coil... The unit of this parameter is henry, and the designation is Gn. The next parameter is the electrical resistance (in direct current), measured in ohms (ohms).

Then there are such characteristics as the allowable voltage, the rated bias current and of course the quality factor, which is an extremely important parameter, especially for oscillating circuits. Different types of chokes are widely used today to solve a wide variety of engineering problems.

Types of chokes

Chokes without coils are designed to suppress high-frequency noise in electrical circuits. They are usually a ferrite core made in the form of a hollow cylinder (or O-ring) through which the wire passes.

The reactivity of such a choke at low frequencies (including industrial frequency) is small, and at high frequencies (0.1 MHz ... 2.5 GHz) it is large. Thus, if high-frequency interference occurs in the cable, then such a choke suppresses it with an insertion loss of 10 ... 15 dB.Manganese-zinc and nickel-zinc ferrites are used to create the magnetic cores of chokes without turns.

AC chokes are widely used as resistors (inductive) resistors, elements of LR- and LC-circuits, as well as in the output filters of AC converters. Such chokes are made with inductances from tenths of microhenries to hundreds of henries for currents from ~ 1 mA to 10 A. They have a single coil located on a magnetic core made of ferro- or ferrimagnetic material.

When designing an AC choke, it is necessary to take into account the following main nominal parameters: the required power (the most permissible value of the current), the frequency of the current, the dignity and the weight.

The quality factor can be increased by various methods. From the point of view of the production of magnetic circuits, it is necessary to take into account that the merit can be increased due to:

-

selection of magnetic material with high magnetic permeability and low losses;

-

increasing the cross-sectional area of the magnetic circuit;

-

introducing a non-magnetic gap.

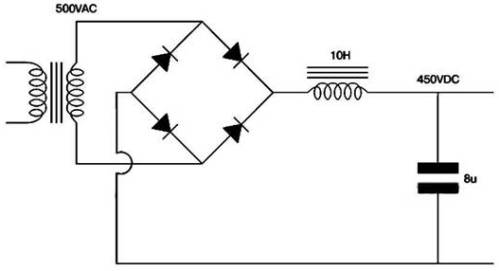

Smoothing chokes — elements of converters designed to reduce the variable component of the voltage or current at the input or output of the converter. Such chokes have a single winding in the current of which (unlike AC chokes) both AC and DC components are present. The choke coil is connected in series with the load.

The choke must have a large inductance (inductive resistance). At its winding, a drop in the alternating component of the voltage is observed, while the constant component (due to the small active resistance of the winding) is released at the load.

The current components create a direct magnetic flux (which acts as a magnetizer) and an alternating flux in the choke magnetic circuit, sinusoidal… Due to the constant component of the current, the magnetic flux (induction) in the magnetic circuit changes in accordance with the initial magnetization curve, while due to the variable component, the magnetization reversal takes place in partial cycles at the corresponding current values.

As the current increases, the alternating component of the magnetic flux decreases (at a constant alternating current component), which leads to a decrease in the differential magnetic permeability and, accordingly, to a decrease in the inductance of the choke. Physically, the decrease in inductance with increasing magnetizing current is due to the fact that as this current increases, the choke's magnetic circuit becomes more and more saturated.

Suffocation from saturation are used as adjustable inductive reactances in AC circuits. Such chokes have at least two windings, one of which (working) is included in the alternating current circuit, and the other (control) - in the DC circuit. The principle of operation of saturation chokes is to use the nonlinearity of the curve B (H) of the magnetic circuits, when they are magnetized by the control and operating currents.

The magnetic circuits of such chokes have no non-magnetic gap. The main characteristics of saturation chokes (compared to smoothing chokes) are the significantly higher value of the variable component of the magnetic flux in the magnetic circuit and the sinusoidal nature of its change.

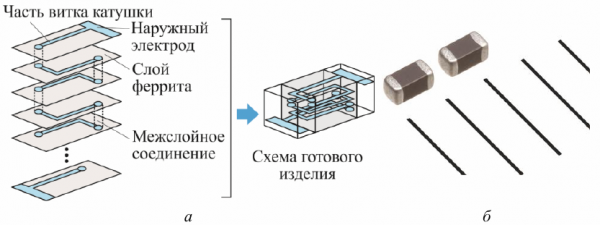

The development of electronic equipment imposes different requirements on chokes, in particular, it requires a reduction in size and a reduction in the level of electromagnetic interference in conditions of high component assembly density. To solve this problem were developed multilayer ferrite chip filters based on a surface mount board.

Such devices are manufactured using thin-film technology. Thin layers of ferrite are deposited on the substrate (for example, the Taiwanese company Chilisin Electronics uses Ni-Zn ferrite), between which a half-turn coil structure is formed.

After deposition of layers, the number of which can reach several hundred, sintering takes place, during which a volume coil with a ferrite magnetic core is formed. Thanks to this design, the stray fields are reduced to a minimum and, accordingly, the mutual influence of the elements on each other is practically excluded, since the lines of force are mainly closed inside the magnetic circuit.

Multilayer filters with ferrite chips: a — production technology; b — appearance related to a scale with a step of 1 mm

Multilayer ferrite chip filters are used to filter high-frequency interference in the power and signal circuits of consumer electronics, power supplies, etc. The main manufacturers of chip filters are Chilisin Electronics, TDK Corporation (Japan), Murata Manufacturing Co., Ltd (Japan), Vishay Intertechnology (USA), etc.

Magnetic core chokes made from carbonyl iron based magneto dielectric are used in radio equipment operating in the range 0.5 … 100.0 MHz.

In chokes, magnetic cores made of all known soft magnetic materials can be used: electrical steels, ferrites, magneto-dielectrics, as well as precision, amorphous and nanocrystalline alloys.

Unlike chokes in transformers, magnetic amplifiers, and similar devices, the magnetic circuit serves to concentrate the magnetic flux while minimizing magnetic losses. In this case, the main function performed by the magnetic circuit practically excludes its manufacture from a magneto-dielectric material that has a low relative magnetic permeability.

A wide range of ferrites of different grades designed to operate in frequency ranges similar to magneto-dielectrics narrows the application range of magneto-dielectrics for manufacturing magnetic circuits of electromagnetic devices.

App for suffocation

So, by purpose, electric chokes are divided into:

AC chokes operating in secondary switching supplies. The coil stores the energy of the primary power source in its magnetic field, then transfers it to the load. Inverting converters, amplifiers - they use chokes, sometimes with multiple windings, like transformers. It works in a similar way magnetic ballast of a fluorescent lamp, used to ignite and maintain the rated current.

Engine starting chokes — starting and braking current limiters. This is more efficient than dissipating power as heat across resistors. For electric drives with a power of up to 30 kW, such a throttle looks similar three-phase transformer (three-phase chokes are used in three-phase circuits).

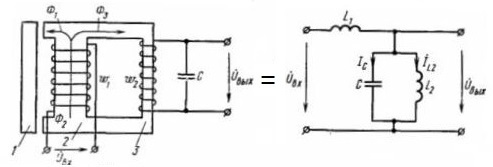

Saturating chokesit is used in voltage stabilizers and ferroresonant converters (the transformer is partially converted into a choke), as well as in magnetic amplifiers, where the core is magnetized in order to change the inductive resistance of the circuit.

Smoothing chokesapplied in filters to remove the rectified current ripple. Smoothing power chokes were very popular during the heyday of tube amplifiers due to the lack of very large capacitors. To smooth the wave after the rectifier, the chokes had to be used just right.

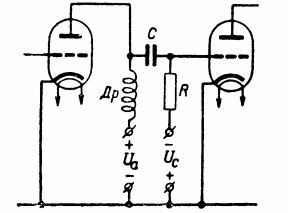

While in power circuits vacuum arc lamps attached throttle boosters — these were special amplifiers in which the chokes served as anode loads for the lamps.

The increased ac voltage released at the choke Dp is fed to the grid of the next lamp through the blocking capacitor C. it is necessary to amplify a relatively narrow frequency range and no great uniformity of gain is required in this band.