Schemes for inclusion and compensation of thermocouples

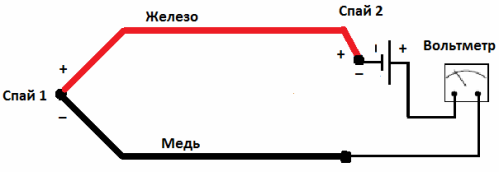

As it is known, the thermocouple contains two junctionstherefore, to correctly and accurately measure the temperature at one (the first) of the junctions, it is necessary to keep the other (the second) junction at some constant temperature, so that the measured EMF is a clear function of the temperature of only the first junction—the main working one crossroad.

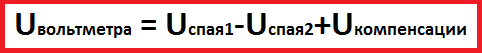

So, in order to maintain conditions in the thermal measuring circuit, in which the parasitic influence of the EMF of the second («cold transition») would be excluded, it is necessary to somehow compensate the voltage on it at each working moment of time. How to do it? How do we get the circuit to such a state that the measured thermocouple voltage would only change depending on changes in the temperature of the first junction, regardless of the current temperature of the second?

To achieve the right conditions, you can resort to a simple trick: place the second junction (the places where the wires of the first junction with the measuring device are connected) in a container of ice water - in a bath full of water with ice still floating in it. Thus, at the second junction we get a practically constant melting temperature of ice.

It will then remain, monitoring the resulting thermocouple voltage to calculate the temperature of the first (operating) junction, since the second junction will be in an unchanged state, the voltage in it will be constant. The goal will eventually be achieved, the influence of the "cold junction" will be compensated. But if you do this, it will turn out to be cumbersome and inconvenient.

Most often, thermocouples are still used in mobile portable devices, in portable laboratory instruments, so another option is gentle, an ice water bath, of course, does not suit us.

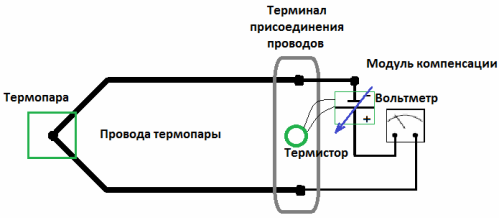

And there is such a different way — the method of compensating the voltage from the changing temperature of the «cold junction»: connect in series to the measuring circuit a source of additional voltage, the EMF of which will have the opposite direction and in magnitude will always be exactly equal to the EMF of « the cold junction».

If the emf of the «cold junction» is continuously monitored by measuring its temperature in a different way from the thermocouple, then an equal compensating emf can be applied immediately, reducing the total parasitic cross-section voltage of the circuit to zero.

But how can you continuously measure the "cold junction" temperature to get continuous voltage values for automatic compensation?

Suitable for this thermistor or resistance thermometerconnected to standard electronics that will automatically generate a compensating voltage of the required magnitude. And while a cold junction is not necessarily literally cold, its temperature is usually not as extreme as a working junction, so even a thermistor is usually fine.

Special electronic compensation modules for «ice melting temperatures» are available for thermocouples whose task is to supply the exact opposite voltage to the measuring circuit.

The value of the compensating voltage from such a module is maintained at such a value as to accurately compensate the temperature of the junction points of the thermocouples leading to the module.

The temperature of the connection points (terminal) is measured with a thermistor or resistance thermometer and the exact required voltage is automatically fed in series in the circuit.

To an inexperienced reader, this may seem like too much trouble for the sake of simply using the thermocouple accurately. Perhaps it would be more expedient and even easier to immediately use a resistance thermometer or the same thermistor? No, it is not simpler and more expedient.

Thermistors and resistance thermometers are not as mechanically robust as thermocouples and also have a small safe operating temperature range. The fact is that thermocouples have a number of advantages, two of which are the main ones: a very wide temperature range (from −250 ° C to +2500 ° C) and a high response speed, which today is unattainable either by thermistors or by resistance thermometers , nor from other sensors.types in the same price range.