Energy conversion process in electrical machines

Electric machines are divided by purpose into two main types: electric generators and electric motors... Generators are designed to generate electric power, and electric motors are designed to drive pairs of wheels of locomotives, turn shafts of fans, compressors, etc.

Electric machines are divided by purpose into two main types: electric generators and electric motors... Generators are designed to generate electric power, and electric motors are designed to drive pairs of wheels of locomotives, turn shafts of fans, compressors, etc.

An energy conversion process takes place in electrical machines. Generators convert mechanical energy into electrical energy. This means that in order for the generator to work, you need to turn its shaft with some kind of engine. On a diesel locomotive, for example, a generator is driven in rotation by a diesel engine, on a thermal power plant by a steam turbine, of a hydroelectric plant — a water turbine.

Electric motors, on the other hand, convert electrical energy into mechanical energy. Therefore, in order for the engine to work, it must be connected by wires to a source of electrical energy, or, as they say, plugged into the electrical network.

The principle of operation of any electric machine is based on the use of the phenomena of electromagnetic induction and the appearance of electromagnetic forces during the interaction of wires with a current and a magnetic field. These phenomena is performed during operation of both the generator and the electric motor. Therefore, they often talk about the generator and motor modes of operation of electrical machines.

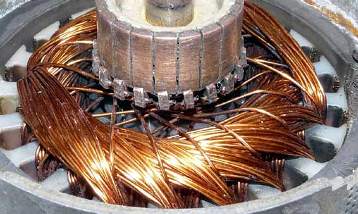

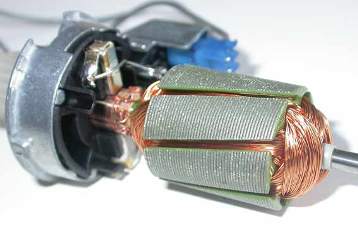

In rotating electrical machines, two main parts are involved in the energy conversion process: the armature and the inductor with its own windings that move relative to each other. The inductor creates a magnetic field in the car. In the armature winding induced by e. with… and an electric current occurs. When the current interacts in the armature winding with a magnetic field, electromagnetic forces are created, through which the energy conversion process in the machine is realized.

For the performance of an energy conversion process in an electric machine

The following provisions derive from the fundamental theorems of electric energy of Poincaré and Barhausen:

1) direct reciprocal transformation of mechanical and electrical energy is possible only if the electrical energy is the energy of alternating electric current;

2) for the implementation of the process of such energy conversion, it is necessary for the system of electric circuits intended for this purpose to have either a changing electrical inductance or a changing electrical capacity,

3) in order to convert the energy of an alternating electric current into the energy of a direct electric current, it is necessary that the system of electric circuits designed for this purpose has a changing electrical resistance.

From the first position it follows that mechanical energy can be converted in an electric machine only into alternating electric current energy or vice versa.

The apparent contradiction of this statement with the fact of the existence of direct current electric machines is resolved by the fact that in a «direct current machine» we have a two-stage conversion of energy.

So, in the case of a direct current electric machine generator, we have a machine in which mechanical energy is converted into alternating current energy and the latter, due to the presence of a special device representing "variable electrical resistance", is converted into energy from DC.

In the case of an electric machine, the process obviously goes in the opposite direction: the energy of direct electric current supplied to an electric machine is converted by means of said variable resistance into alternating electric current energy, and the latter into mechanical energy.

The role of the said changing electrical resistance is played by the "sliding electrical contact", which in a conventional "DC collector machine" consists of an "electric machine brush" and an "electric machine collector", and in slip rings " .

Since in order to create an energy conversion process in an electric machine, it is necessary to have either "variable electric inductance" or "variable electric capacitance" in it, an electric machine can be made either on the principle of electromagnetic induction, or on the principle of electrical induction. In the first case we get an "inductive machine", in the second - a "capacitive machine".

Capacitance machines are still of no practical importance.Used in industry, in transport and in everyday life, electric machines are inductive machines, behind which in practice the short name "electric machine" has taken root, which is essentially a broader concept.

The principle of operation of an electric generator.

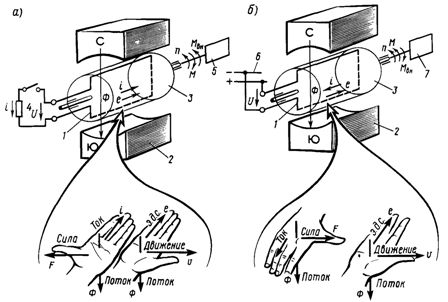

The simplest electric generator is a loop rotating in a magnetic field (Fig. 1, a). In this generator, turn 1 is the armature winding. The inductor is permanent magnets 2, between which the armature 3 rotates.

Rice. 1. Schematic diagrams of the simplest generator (a) and electric motor (b)

When the coil rotates with a certain rotation frequency n, its sides (conductors) cross the magnetic field lines of the flux Ф and e is induced in each conductor. etc. s. d. With the adopted in fig. 1 and the direction of rotation of the armature e. etc. c. in the conductor located under the south pole, according to the right-hand rule, is directed away from us, and e. etc. v. in a wire located under the North Pole - towards us.

If you connect a receiver of electrical energy 4 to the armature winding, then an electric current I will flow through a closed circuit. In the wires of the armature winding, the current I will be directed in the same way as e. etc. s. d.

Let's understand why, in order to rotate the armature in a magnetic field, it is necessary to spend mechanical energy obtained from a diesel engine or a turbine (prime engine). When current i flows through wires located in a magnetic field, an electromagnetic force F acts on each wire.

With the indicated in fig. 1, and the direction of the current according to the left-hand rule, the force F directed to the left will act on the conductor located under the South Pole, and the force F directed to the right will act on the conductor located under the North Pole.These forces together create an electromagnetic moment M. in the clockwise direction.

From an examination of FIG. 1, but it can be seen that the electromagnetic moment M, which occurs when the generator emits electrical energy, is directed in the opposite direction to the rotation of the wires, therefore it is a braking moment that tends to slow down the rotation of the generator armature.

To prevent the anchor from stalling, it is necessary to apply an external torque Mvn to the armature shaft, opposite and equal in magnitude to the moment M. Taking into account friction and other internal losses in the machine, the external torque must be greater than the electromagnetic moment M created by the generator load current.

Therefore, to continue the normal operation of the generator, it is necessary to supply it with mechanical energy from the outside - to rotate its armature with each engine 5.

At no load (with the external generator circuit open), the generator is in idle mode. In this case, only the amount of mechanical energy from the diesel or turbine is required to overcome friction and compensate for other internal energy losses in the generator.

With an increase in the load on the generator, that is, the electric power REL given by it, the current I passing through the wires of the armature winding and the braking torque M. turbines to continue normal operation.

Thus, the more electrical energy is consumed, for example, by the electric motors of a diesel locomotive from a diesel locomotive generator, the more mechanical energy it takes from the diesel engine turning it, and the more fuel must be supplied to the diesel engine.

From the operating conditions of the electric generator, considered above, it follows that it is characteristic of it:

1. matching in direction of current i and e. etc. v. in the wires of the armature winding. This indicates that the machine is releasing electrical energy;

2. the appearance of an electromagnetic braking moment M directed against the rotation of the armature. This implies the need for a machine to receive mechanical energy from the outside.

The principle of the electric motor.

In principle, the electric motor is designed in the same way as the generator. The simplest electric motor is a turn 1 (Fig. 1, b), located on the armature 3, which rotates in the magnetic field of poles 2. The conductors of the turn form an armature winding.

If you connect the coil to a source of electrical energy, for example, to an electrical network 6, then an electric current I will begin to flow through each of its wires. This current, interacting with the magnetic field of the poles, creates electromagnetic forces F .

With the indicated in fig. 1b, the direction of the current on the conductor located under the south pole will be affected by the force F directed to the right, and the force F directed to the left will act on the conductor located under the north pole. As a result of the combined action of these forces, an electromagnetic torque M directed counterclockwise is created, which drives the armature with the wire to rotate with a certain frequency n... If you connect the armature shaft to any mechanism or device 7 (center axis of a diesel locomotive or electric locomotive, metal cutting tool, etc.), then the electric motor will set this device in rotation, that is, give it mechanical energy.In this case, the external moment MVN created by this device will be directed against the electromagnetic moment M.

Let's understand why electrical energy is consumed when the armature of an electric motor operating under load rotates. It was found that when the armature wires rotate in a magnetic field, e is induced in each wire. etc. with, the direction of which is determined according to the right-hand rule. Therefore, with the indicated in fig. 1, b direction of rotation of e. etc. c. e induced in the conductor located under the south pole will be directed away from us, and e. etc. s. e induced in the conductor located under the north pole will be directed towards us. Fig. 1, b it is seen that e., etc. c. That is, the induced in each conductor are directed against the current i, that is, they prevent its passage through the conductors.

In order for the current to continue to flow through the armature wires in the same direction, that is, so that the electric motor continues to work normally and develop the necessary torque, it is necessary to apply an external voltage U to these wires directed to e. etc. c. and greater than the general e. etc. c. E induced in all the series-connected wires of the armature winding. Therefore, it is necessary to supply electrical energy to the electric motor from the network.

In the absence of load (external braking torque applied to the motor shaft), the electric motor consumes a small amount of electrical energy from an external source (mains) and a small current flows through it at idle. This energy is used to cover the internal power losses in the machine.

As the load increases, so does the current consumed by the electric motor and the electromagnetic torque it develops. Therefore, an increase in the mechanical energy released by the electric motor as the load increases automatically leads to an increase in the electricity it draws from the source.

From the operating conditions of the electric motor discussed above, it follows that it is characteristic of it:

1. coincidence in the direction of the electromagnetic moment M and speed n. This characterizes the return of mechanical energy from the machine;

2. the appearance in the wires of the armature winding e. etc. directed against the current i and the external voltage U. This implies the need for the machine to receive electrical energy from the outside.

The principle of reversibility of electrical machines

Considering the principle of operation of a generator and an electric motor, we found that they are arranged in the same way and that there is much in common in the basis of the operation of these machines.

The process of converting mechanical energy into electrical energy in the generator and electrical energy into mechanical energy in the motor is related to the induction of EMF. etc. pp. in the wires of the armature winding rotating in a magnetic field and the emergence of electromagnetic forces as a result of the interaction of the magnetic field and the current-carrying wires.

The difference between a generator and an electric motor is only in the mutual direction of e. d. with, current, electromagnetic torque and speed.

Summarizing the considered generator and electric motor operation processes, it is possible to establish a principle of reversibility of electric machines... According to this principle, any electric machine can work as a generator and an electric motor and switch from generator mode to motor mode and vice versa.

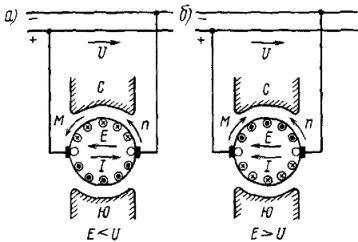

Rice. 2. Direction of e., etc. with E, current I, armature rotation frequency n and electromagnetic moment M during operation of a direct current electric machine in motor (a) and generator (b) modes

To clarify this situation, consider work Direct current electric machine under different conditions. If the external voltage U is greater than the total e. etc. v. D. in all the series-connected wires of the armature winding, then the current I will flow in that indicated in fig. 2, and the direction and machine will work as an electric motor, consuming electrical energy from the network and giving out mechanical energy.

However, if for some reason e. etc. c. E becomes greater than the external voltage U, then the current I in the armature winding will change its direction (Fig. 2, b) and coincide with e. etc. v. D. In this case, the direction of the electromagnetic moment M will also change, which will be directed against the frequency of rotation n... Coincidence in the direction d., etc. with E and current I means that the machine has begun to give electrical energy to the network, and the appearance of a braking electromagnetic moment M indicates that it must consume mechanical energy from the outside.

Therefore, when e. etc. withE induced in the wires of the armature winding becomes greater than the mains voltage U, the machine switches from the motor operation mode to the generator mode, that is, when E < U the machine works as a motor, with E> U — as a generator.

The transfer of an electric machine from motor mode to generator mode can be done in different ways: by reducing the voltage U of the source to which the armature winding is connected, or by increasing e. etc. with E in the armature winding.