Selection of power of the electric motor of the pumping unit

To choose the type and capacity of the electric pumping installation, it is necessary to decide on the water supply scheme based on local conditions. Water is mainly supplied by a water pressure boiler or a water pressure tank driven by centrifugal pumps by asynchronous motors.

To choose the type and capacity of the electric pumping installation, it is necessary to decide on the water supply scheme based on local conditions. Water is mainly supplied by a water pressure boiler or a water pressure tank driven by centrifugal pumps by asynchronous motors.

The direct supply of water from the pump to the distribution network is carried out in open irrigation systems driven by asynchronous motors.

For the adopted water supply scheme, choose a pump (in most cases, a reliable and easy-to-use centrifugal pump).

To select a pump and determine its power by water consumption, the required flow and pressure are determined.

Feeding Qn (l / h) of the pump is found from the following ratio:

Bn = Qmaxh = (kz NS kdays x VWednesday) / (24 η),

where Qmaxh is the maximum possible hourly flow of water, l / h, kz — coefficient of irregularity of hourly consumption, kdni — coefficient of irregularity of daily consumption (1.1 — 1.3), η — efficiency of the unit, taking taking into account water losses), WEDNESDAY day — average daily water consumption, l / day.

Given that the pressure H = P /ρg, where P — pressure, Pa, ρ — density of liquid, kg / m3, g — 9.8 m / s2 — acceleration of gravity, g — specific weight of liquid, k / m3, we get:

Hntr = Hc + Hn + (1 /ρ) NS (Rov — Pnu)

Knowing the required flow rate and head, a pump with suitable parameters is selected from the catalog, taking into account the possible speed of the drive motor. Next, the power of the pump's electric motor is determined.

According to the universal characteristic of the selected pump, its power supply Qn pressure Hn is determined and the efficiency ηn and pump power Rn are determined.

Power (kW) of the pump drive motor Pdv = (ks NS ρ NS Qn x Hn) / (ηn x ηn),

where — кс factor of safety, depending on the power of the electric motor of the pump: P, kW — (1.05 — 1.7), since in real conditions of operation of pumps, leakage of water from the pressure pipeline may occur (due to leakage of connections, pipeline breaks, etc., therefore, electric motors for pumps are selected with a certain power reserve. a lower safety factor can be taken, so for a pump motor power of 2 kW — кс = 1.5, 3 kW — кс = 1.33, 5 kW — кz = 1.2, with power over 10 kW- кh = 1.05 — 1.1. ηπ — Transmission efficiency (for direct transmission 1, V-belt 0.98 , gear 0.97, flat belt 0.95), ηn — efficiency of piston pumps 0.7 — 0.9, centrifugal 0.4 — 0.8, vortex 0.25 — 0.5.

From these ratios, it follows that as the angular speed of the pump increases, its power increases, which can lead to overheating of the electric motor. If the angular velocity of the motor is underestimated, the pump head may be insufficient for the calculated flow rate.

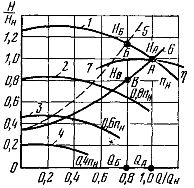

When choosing an electric pump unit according to the catalog, it is necessary to take into account its operational characteristics (Fig. 1) and the characteristics of the line on which the pump works, that is, the connection between the power supply and the total value of the pressure required to raise the water to a certain height , overcoming hydraulic resistance and creating an excess pressure at the outlet of the discharge pipeline.It is necessary to strive to ensure that the operating point A is in the zone of the maximum values of the efficiency of the unit.

Rice. 1. Characteristics of the pump at different speeds (1, 2, 3, 4), lines at different degrees of throttling (5, 6) and efficiency (7) of the pump at the rated speed.

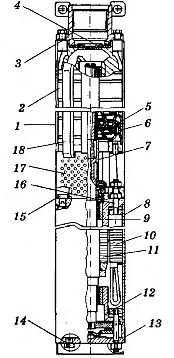

The type of electric motor is selected based on environmental conditions and installation characteristics. For example, to drive submersible pumps of the ETsV type, electric motors with a power of 0.7 — 65 kW with a special construction of the PEDV type are used, designed for work in boreholes with a diameter of 100 to 250 mm with power supply at a height of up to 350 m. isolation.

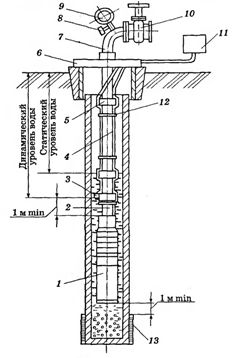

The electric motor together with the pump is installed in the well immersed in the pumped water (Fig. 3). An example of a conventional unit designation: ETsV-6-10-80-M, where ETsV-6 is an electric water pump drilling unit with a characteristic "6" in the diameter of the well, namely for a well with an internal diameter of 149.5 mm, 10 is the nominal flow rate of the pump, m3 / h, 80 — nominal pressure, m, M — type of climate version according to GOST 15150-69.

Conventional designation of the electric motor used in the device: PEDV4-144 (PEDV — water-immersed submerged electric motor, 4 — rated power, kW, 144 — maximum cross-sectional size, mm).

Rice. 2. Electric centrifugal water pump unit: 1 — pump, 2 — cage, 3 — head, 4 — check valve, 5 — impeller, 6 — vane outlet, 7 — coupling, 8 — motor, 9 — upper bearing, 10 — stator, 11 — rotor, 12 — lower bearing shield, 13 — bottom, 14 — plug, 15 — filter plug, 16 — hairpin, 17 — mesh, 18 — housing

Rice. 3.Location of the block in the well: 1 — block, 2 — water intake column, 3 — sensor for «dry operation», 4 — cable, 5 — connector, 6 — base plate or head, 7 — elbow, 8 — three-way valve, 9 — pressure gauge, 10 — valve, 11 — control and protection station, 12 — clamp, 13 — filter

Submersible electric pumps, depending on the level of subsidence of the aquifer, work at depths of 40 — 230 m.

The mechanical characteristics of the centrifugal pump are fan-type. The frictional moment of resistance in the pump bearings Ms — 0.05 Mn.

The average torque of a reciprocating pump when operating on a line where a constant head is maintained does not depend on the angular velocity of rotation. The piston pump is started with an open valve on the discharge line. Otherwise, an accident may occur.

The centrifugal pump can be started both with the discharge line valve open and closed.

Taking into account the environmental conditions, the characteristics of the installation, the required power and the speed of the pump, the appropriate type of electric motor is selected from the reference tables.