Selection of motors for cyclic action mechanisms

Electric actuators with cyclic action operate in a periodic mode, a characteristic feature of which is frequent starting and stopping of the motor. It is known from the course of the theory of electric drive that the energy losses in transient processes directly depend on the moment of inertia of the electric drive J∑, the main part of which, if we exclude inertial mechanisms, is the moment of inertia of the motor Jdv. Therefore, in cut-off mode it is desirable to use motors which, at the required power and angular velocity, have possibly the smallest moment of inertia Jdv.

Electric actuators with cyclic action operate in a periodic mode, a characteristic feature of which is frequent starting and stopping of the motor. It is known from the course of the theory of electric drive that the energy losses in transient processes directly depend on the moment of inertia of the electric drive J∑, the main part of which, if we exclude inertial mechanisms, is the moment of inertia of the motor Jdv. Therefore, in cut-off mode it is desirable to use motors which, at the required power and angular velocity, have possibly the smallest moment of inertia Jdv.

According to the heating conditions, the allowable load of the motor in intermittent operation is higher than in continuous operation. When starting with enlarged static load motor must also develop an increased starting torque exceeding the static by the value of the required dynamic torque. Therefore, intermittent operation requires a greater motor overload capacity than long-term operation.The requirement for a high overload capacity is also determined by the need to overcome short-term mechanical overloads resulting from the separation of loads, soil excavation, etc.

Finally, the heating and cooling conditions of engines in intermittent operation differ from those in continuous operation. This difference is particularly pronounced in self-ventilated engines, since the amount of cooling air entering the engine depends on its speed. During transients and pauses, the heat dissipation of the engine is impaired, which has a significant impact on the permissible engine load.

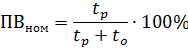

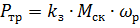

All these conditions determine the need to use in electric drives with cyclic action mechanisms special motors whose nominal load is periodic, characterized by a certain nominal duty cycle

where Tp and se — the working time and the pause time, respectively.

In intermittent mode, when operating at rated load, the engine temperature fluctuates around the permissible value, increasing during operation and decreasing during pause. It is obvious that the higher the temperature deviations from the admissible, the longer the cycle time at a given PV Tq = Tp + se and the smaller the time constant of engine heating Tn.

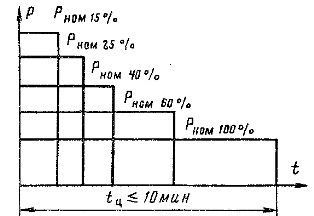

To the limit of possible maximum engine temperature, limit the allowable cycle time. For household engines with intermittent operation, the allowable cycle time is set equal to 10 minutes. Thus, these motors are designed for a duty cycle whose graph for standard duty times (duty cycle = 15, 25, 40 and 60 and 100%) is shown in Fig. 1.As the duty cycle increases, the rated power of the motor decreases.

The industry produces a number of series of intermittent load motors:

— asynchronous cranes with a squirrel rotor in the MTKF series and with a phase rotor in the MTF series;

— similar metallurgical series MTKN and MTN;

— DC series D (in the version for DE series excavators).

Machines of the specified series are characterized by the shape of an elongated rotor (armature), which provides a reduction in the moment of inertia. In order to reduce the losses released in the stator winding during transient processes, the motors of the MTKF and MTKN series have an increased nominal slip sHOM = 7 ÷ 12%. The overload capacity of the motors of the crane and metallurgical series is 2.3 — 3 at duty cycle = 40%, which at duty cycle = 100% corresponds to λ = Mcr / Mnom100 = 4.4-5.5.

V crane motors AC mode is taken as the main rated mode with duty cycle = 40%, and in DC motors - short-time mode with a duration of 60 minutes (together with duty cycle = 40%). The nominal powers of the engines of the crane and metallurgical series at PVNOM = 40% are in the range: 1.4-22 kW for the MTF and MTKF series; 3-37 kW and 3-160 kW for MTKN and MTN series respectively; 2.4-106 kW for D series. D series blown motors are made for rated power from 2.5 to 185 kW with duty cycle = 100%.

Squirrel cage motors can have a multi-speed design with two or three separate stator windings: MTKN series with the number of poles 6/12, 6/16 and 6/20 and rated power from 2.2 to 22 kW at PVNOM = 40% ; MTKF series with number of poles 4/12, 4/24 and 4/8/24 and rated power from 4 to 45 kW at PVN0M = 25%.The production of a new 4MT series of asynchronous crane and metallurgical motors in the power range of 2.2 — 200 (220) kW with a duty cycle of 40% is planned.

The use of two-motor drive doubles the range of application of the listed types of electric machines. With large required powers, asynchronous motors of the A series, AO, AK, DAF, etc. are used, as well as DC motors of the same P series in specialized modifications, for example, in the version for excavators of PE, MPE, for Elevators MP L, etc.

Selection of engines for crane and metallurgical series is most simply carried out in cases where its actual working schedule coincides with one of the nominal ones shown in fig. 1. Catalogs and reference books list motor ratings at PV-15, 25, 40, 60 and 100%. Therefore, when the drive operates with a constant static load Pst at rated cycle, it is not difficult to select a motor with the closest power from the catalog from the condition PNOM > Rst.

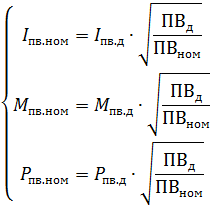

However, real cycles are usually more complex, the engine load in different parts of the cycle turns out to be different, and the switching time differs from the nominal one. Under such conditions, the selection of the engine is carried out according to an equivalent schedule, aligned with one of the nominal ones in fig. 1. For this purpose, the permanent equivalent heating load is first determined at a valid PST, which is then recalculated to the standard PST0M switch-on duration. The recalculation can be done using the ratios:

The ratios are approximate because they do not take into account two important factors that change with a change in duty cycle and significantly affect engine heating.

Rice. 1.The rated duty cycle of the motor for intermittent duty.

The first factor is the amount of heat released in the motor due to constant losses… This amount of heat increases as PV increases and decreases as PV goes down. Accordingly, when you go to a large photovoltaic device, the heating increases and vice versa.

The second factor is the ventilation conditions of the engines. With self-ventilation, the cooling conditions during periods of work are several times better than during periods of rest. Therefore, with an increase in PV, the cooling conditions improve, with a decrease, they deteriorate.

Comparing the influence of these two factors, we can conclude that it is opposite and to some extent mutually compensated. Therefore, for modern series, the approximate ratios give a fairly correct result if they are used only for recalculation to the nominal duty cycle closest to the hydroelectric power plant.

It is known from the theory of electric propulsion that the methods of average losses and equivalent values used in the selection of a motor are of a verification nature, since they require knowledge of a number of parameters of a previously selected motor. When making a preliminary selection, in order to avoid multiple errors, it is necessary to take into account the characteristics of a particular mechanism.

For general industrial mechanisms of cyclic action, you can specify the three most typical cases of motor preselection:

1. The duty cycle of the mechanism is set, and dynamic loads have a negligible effect on engine heating.

2. The cycle of the mechanism is set, and dynamic loads are known to significantly affect engine heating.

3. The cycle of the mechanism is not determined by the task.

The first case is most typical for mechanisms with low inertial masses — single-use lifting and traction winches. The effect of dynamic loads on engine heating can be assessed by comparing the start-up duration tp with the duration of steady-state operation.

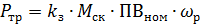

If tп << tyct the motor selection can be made according to the drive load diagram. According to this load diagram, the average load torque is determined by the formulas given earlier, it is recalculated to the nearest rated duty cycle, and then the required engine power is determined at a given operating speed ωρ:

In this case, an approximate account of the influence of dynamic loads is carried out by introducing a safety factor kz = 1.1 ÷ 1.5 in the formula. As the ratio tp / tyct increases, the safety factor should increase approximately, assuming that at tp / tyct0.2 — 0.3 it is more.

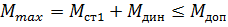

The pre-selected motor must be checked for heating by one of the methods according to the theory of electric drive, as well as overload capacity from the condition:

where Mdop is the allowable short-term overload moment.

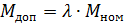

For DC motors, the torque is limited by the current commutation conditions on the collector:

where λ is the overload capacity of the motor according to the catalog data.

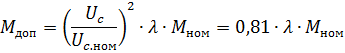

For asynchronous motors, when determining Mdop, it is necessary to take into account the possibility of reducing the mains voltage by 10%. Since the critical moment Mcr is proportional to the square of the stress, then

In addition, squirrel-cage induction motors should be checked in the same way by starting torque.

The second case is characteristic of mechanisms with large inertial masses - heavy and high-speed mechanisms of movement and rotation, but it can also be realized in other cases with a high starting frequency.

Here, the influence of dynamic loads can be evaluated by comparing the transient time and steady-state operation. If they are commensurable or tp> tact, the dynamic loads cannot be neglected even when the engine is preselected.

In this case, it is necessary to construct for the preliminary selection an approximate load diagram of the motor, having set, by analogy with the current settings, its moment of inertia. If Jdw << Jm, an error in the value of Jdw cannot have a significant effect on the correctness of the selection, and furthermore the subsequent verification calculation gives the necessary clarifications in each case.

Finally, the third case is characteristic of mechanisms of universal purpose, for which it is difficult to build a specific work cycle. An example of this is the mechanisms of a normal overhead traveling crane with a low load capacity, which can be used in various production areas.

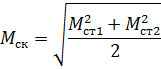

The basis for choosing an engine in such cases can be a settling cycle, where on the first working section tp1 the engine works with maximum load MCT1, and on the second tp2 with minimum load MCT2. If it is known that the influence of dynamic loads on the heating of the motor of this mechanism is small, it is possible to determine the rms (equivalent on heating) load moment, assuming tp1 = tp2

The required engine power at a given operating speed is determined by the ratio

The selection of the motor according to the catalog is made by the condition Ptr < Pnom at the calculated duration of inclusion of PVnom set for the mechanism.

For crane mechanisms, the rules establish the following modes of operation, determined by the totality of their operating conditions:

- light — L (PVNOM == 15 ÷ 25%, the number of starts per hour h <60 1 / h),

- medium — C (PVNOM = 25 — 40%, h <120 1 / h),

- heavy — T (PVNOM = 40%, h < 240 1 / h)

- very heavy — HT (DFR = 60%, h < 600 1 / h).

- especially heavy — OT (duty cycle = 100%, h> 600 1 / h).

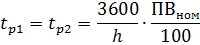

The availability of these data, based on statistical materials, allows, if necessary, to specify the conditional cycle of the mechanism, accepted above as calculated. In fact, the working time is fixed

which allows the engine to be pre-selected in the same ways as in the first two cases discussed above. This is particularly important when the effect of dynamic loads on engine heating can be assumed to be significant.