Soldering technology

Soldering, as one of the technologies for forming permanent joints, is a unique way to connect a wide variety of materials - metals, non-metals, as well as combinations of metal with non-metals (carbon, alloy, high-speed steel, non-ferrous metals and their alloys - copper, aluminum, hard alloys, semiconductors, ceramics, etc.).

Soldering, as one of the technologies for forming permanent joints, is a unique way to connect a wide variety of materials - metals, non-metals, as well as combinations of metal with non-metals (carbon, alloy, high-speed steel, non-ferrous metals and their alloys - copper, aluminum, hard alloys, semiconductors, ceramics, etc.).

The quality of soldered joints largely depends on the preparatory operations: cleaning surfaces, applying basecoats, placing the soldering material, pre-assembling the product into fasteners and testing the soldering mode.

Cleaning of surfaces should ensure the removal of oxides and fatty contaminants that prevent capillary withdrawal of the material of the workpiece and the solder. Cleaning before soldering is carried out by two methods - chemical and mechanical. Mechanical cleaning is used to remove coarse dirt (rust, oxides, etc.), and chemical cleaning is used to remove grease and light dirt (wiping with alcohols — ethyl, butyl, methyl, special cleaning mixtures).In case of chemical degreasing, the need for subsequent rinsing of the composition should be taken into account.

Mechanical cleaning is carried out by an abrasive jet (sand, shot) for large surfaces, metal brushes, lathe processing, grinding machines. Dust removal is also necessary after dry blasting. Soldering should begin as soon as possible after cleaning to avoid re-formation of oxides.

Applying basecoats is used to improve the fluidity of the solder. Copper coatings are most often used. Corrosion-resistant steels are also nickel-plated. Copper coatings are applied by soldering or electrolytic deposition.

Solder placed either near the gap in the form of wire, profiled foil, paste, etc., or directly in the gap. Another way is to feed the solder during the soldering process - manual or mechanized. The solder is fixed by gluing or welding.

When applying solder in the gap, the electrical deposition method is widely used (for tin, titanium, copper, various alloys). Plasma spraying of coatings is also used. In contact-reactive soldering, a foil (or sprayed coating) is placed in the gap, forming a contact pair with the metal of the workpiece.

In order to protect surfaces that cannot be soldered, special «stop pastes» of silicon dioxide (Al2O3), graphite, zirconium oxide and others are used.

Pre-fixing of parts manufactured to maintain a certain clearance and relative position of the parts.In this case, both demountable connections (mounting in devices, pressing) and one-component (heating, assembly by spot, resistance or arc welding) can be used.

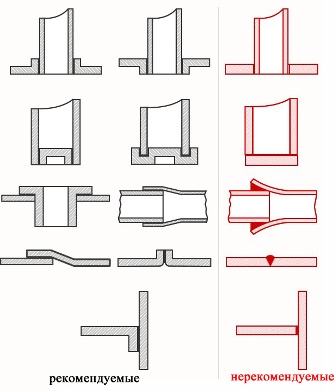

Designs for soldering joints

The main parameters of the soldering mode are:

-

soldering temperature,

-

heating rate,

-

keeping time

-

pressure force (for pressure soldering),

-

cooling rate.

Soldering temperature is determined based on the maximum allowable value for soldering these materials, and the solder is selected so that its liquidus temperature is 20-50 degrees lower than the soldering temperature.

Heating speed essential for thin-walled parts. It is determined empirically.

Holding time at the soldering temperature is also determined empirically based on the fact that it must ensure the process of wetting and spreading. At the same time, it is not recommended to unreasonably increase its value, as this can lead to erosion of the metal of the workpiece from the action of molten solder.

Heating to melt the solder can be done in different ways — manually (using torches, soldering irons), in furnaces, inductive and contact methods.

After soldering, cleaning must be carried out, which, as a rule, is carried out in two stages. The first is the elimination of soldering waste. The second is stripping to remove the oxide layers formed during the flux soldering process. Failure to adhere to aggressive flux residues can weaken solder joints.

Since most solder fluxes are water soluble, the best way to remove them is to rinse the assembly in hot water (50 degrees or more). It is best to submerge the assembly in water while the soldered parts are still hot. If necessary, the flux can be lightly rubbed with a wire brush. More sophisticated flux removal methods—fine ultrasonic cleaning—can be used to accelerate exposure to hot water or steam.

Sometimes it is necessary to remove the flux from the overheated parts of the solder. In such cases, the flux is completely saturated with oxides and turns green or black. In this case, it must be removed with a dilute solution of hydrochloric acid (concentration 25%, heating temperature 60-70 degrees, exposure 0.5 ... 2 minutes). In this case, you must observe all precautions when working with acids.

After the solder is cleaned of flux residue, the oxides are removed. The best cleaning agents are those recommended by the manufacturer of the solder used for soldering. Acidic solutions can also be used, but nitric acid, for example, destroys silver solders during etching.

After removing the flux and oxides, soldered joints can be subjected to a number of other finishing operations - polishing or oil preservation.

Defects during the soldering process are similar to welded ones: non-drip, non-metallic inclusions, pores and cavities, cracks. Non-soldering can occur when the gap and heating are uneven, when there is not enough wetting or there is no gas outlet.

Non-metallic inclusions in the soldered joint appear when the solder interacts with the oxygen contained in the air, from the interaction of the flux with the metal of the workpiece during prolonged heating and with poor pre-cleaning of the surfaces. Pores and voids can form with large gaps and if the solubility of gases decreases during weld crystallization.

Cracks can result from thermal stresses during cooling of parts or from the formation of brittle intermetallic compounds.

By observing the soldering regime, thorough cleaning and ensuring optimal clearance between the parts to be soldered, the risk of defects in the soldered joints is significantly reduced.

See also: Soldering pins and wires