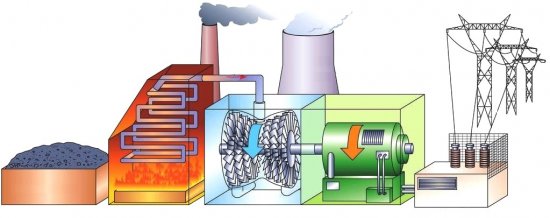

How electricity is produced in a thermal power plant (CHP)

Thermal power plants are divided into stations:

-

according to the type of propulsion engine — steam turbine, gas turbine, with internal combustion engines;

-

by type of fuel — with solid organic fuel (coal, firewood, peat), liquid fuel (oil, gasoline, kerosene, diesel fuel), running on gas.

In thermal power plants, the energy of the burned fuel is converted into thermal energy, which is used to heat the water in the boiler and generate steam. Steam energy drives a steam turbine connected to a generator.

Thermal power plants in which steam is used entirely to produce electricity are called condensing power plants (CES). Powerful IES are located near fuel production areas, remote from electricity consumers, therefore electricity is transmitted at high voltage (220 — 750 kV). Power plants are built in blocks.

Cogeneration power plants or combined heat and power plants (CHP) are widely used in cities.In these power plants, the steam partially exhausted in the turbine is used for technological needs, as well as for heating and hot water in residential and communal services. The simultaneous production of electricity and heat reduces the cost of supplying electricity and heat compared to the separate production of electricity and heat.

Thermal power plants use the heat generated by burning fossil fuels such as oil, gas, coal or fuel oil to produce large amounts of high-pressure steam from water. As you can see, the steam here, despite acting as a coolant from the age of steam engines, is still perfectly capable of turning a turbine generator.

Steam from the boiler is fed to a turbine, with a shaft connected to a three-phase alternating current generator. The mechanical energy of the turbine rotation is converted into electrical energy of the generator and transmitted to consumers at generator voltage or at step-up voltage through step-up transformers.

The pressure of the supplied steam in the turbine is about 23.5 MPa, while its temperature can reach 560 ° C. And the water is used in a thermal power plant precisely because it is heated by the fossil organic fuel typical for such plants, whose reserves are in the depths of our planet are still quite large, although they give a huge minus in the form of harmful emissions that pollute the environment.

So the rotating rotor of the turbine is connected here to the armature of a turbine generator of huge power (several megawatts) which ultimately generates electricity in this thermal power plant.

In terms of energy efficiency, thermal power plants are generally such that the conversion of heat into electricity is carried out on them with an efficiency of about 40%, while a very large amount of heat in the worst case is simply thrown into the environment and in the worst - in the best case, it is immediately supplied to the heating and hot water, the water supply to the nearby consumers. Thus, if the heat released in a power plant is immediately used for heat supply, then the efficiency of such a plant generally reaches 80%, and the station is called a combined heat and power plant or TPP.

The most common generator turbine of a thermal power plant contains on its shaft a plurality of wheels with blades spaced in two separate groups. The steam under the highest pressure, that which is discharged from the boiler, immediately enters the flow path of the generator set, where it turns the first set of vane impellers. In addition, the same steam is further heated in a steam heater, after which it enters the second group of wheels operating at a lower steam pressure.

As a result, the turbine, connected directly to the rotor of the generator, makes 50 revolutions per second (the magnetic field of the armature, which crosses the stator winding of the generator, also rotates at the corresponding frequency). To prevent the generator from overheating during operation, the station has a cooling system for the generator that prevents it from overheating.

A burner is installed inside the boiler of a thermal power plant, on which the fuel is burned, forming a high-temperature flame. For example, coal dust can be burned with oxygen.The flame covers a large area of a pipe with a complex configuration with water passing through it, which, when heated, becomes steam escaping to the outside under high pressure.

Water vapor flowing out under high pressure is fed to the blades of the turbine, transferring its mechanical energy to it. The turbine rotates and the mechanical energy is converted into electrical energy. Overcoming the system of turbine blades, the steam is directed to the condenser, where, falling on the pipes with cold water, it condenses, that is, it becomes a liquid again - water. Such a thermal power plant is called a condensing power plant (CES).

Combined heat and power plants (CHP), unlike condensing power plants (CES), contain a system to extract heat from steam after it has passed through the turbine and already contributed to the production of electricity.

The steam is taken with different parameters, which depends on the type of particular turbine, and the amount of steam taken from the turbine is also regulated. The steam taken to generate heat is condensed in the network boilers, where it gives its energy to the network water, and the water is pumped to the peak hot water boilers and heating points. In addition, water is supplied to the heating system.

If necessary, extraction of heat from steam in the thermal power plant can be completely turned off, then the combined heat and power plant will become a simple IES. Thus, the thermal power plant is able to operate in one of two modes: in thermal mode — when the priority is to generate heat, or in electric mode — when the priority is electricity, for example in summer.