Electrostatic painting - design and principle of operation

The electrostatic paint sprayer was first patented between 1941 and 1944 by American scientist and researcher Harald Ransburg. Before he patented his invention and after he patented the first versions of it, Ransburg experimented extensively in the laboratory, perfecting the electrostatic paint application method he had invented.

So, in 1951, the inventor received patent US 2697411 for a device for applying paint by electrostatic spraying, which became the prototype of modern tools. In the same years, Harald founded the company Ransburg, which is still engaged in the production and improvement of electrostatic painting equipment.

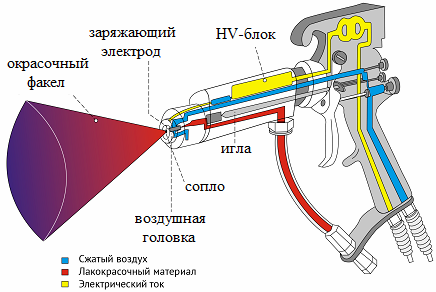

Basically, the method is as follows. The liquid material for paint and varnish is sprayed as usual with a sprayer, but with one additional condition. When passing through the spray gun, the paint is charged, in contact with a special electrode near the nozzle of the spray gun, to a high negative voltage, the level of which reaches 100,000 volts.

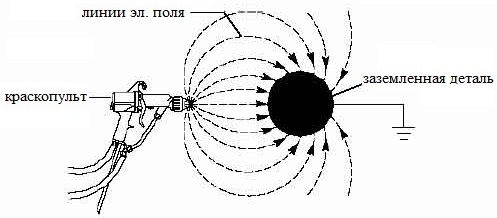

After exiting the nozzle, the negatively charged paint particles rush in the direction of the field lines electrostatic field to the grounded paint product. That is, a high voltage is applied between the spray gun and the product to be painted.

Spraying of the paint is carried out with the help of compressed air, i.e. pneumatic method or airless spraying, where pressurized paint is rushed through the nozzle opening. These are the two traditional spray patterns for applying electrostatic paint. There are also combined systems.

Furthermore, the paint particles of equal charge flying out of the nozzle repel each other according to the law of electrostatics, naturally forming a paint torch. The torch of particles is rushed by the forces of electrostatic attraction to the grounded part, and the particles, moving along the lines of the intensity of the electrostatic field, uniformly cover the part. As such, there is no ink mist effect, and the transfer coefficient of the paint and varnish material on the product reaches 98%.

This method of application allows you to significantly save paint and varnish material and, in general, significantly speeds up the painting process. When painting large objects, such as pipes, in the usual way, they must be turned several times during the painting process so that the paint lies evenly and on all sides.

But with electrostatic application, this is already superfluous, since the charged paint particles move along the lines of the electric field by themselves, bend around the product from all sides, and one pass with a spray gun is enough to get the necessary high-quality result.

Electrostatic guns are different, but also have something in common with traditional spray guns. First of all, the principle of the channels conducting the paint is the same. The difference lies in the presence in some and in the absence of others of an electrode for charging the paint and varnish material, as well as of high voltage, which provides the system with the necessary working voltage.

The body of the electrostatic spray gun, unlike the usual one, is not made of steel or aluminum, but of a composite plastic containing both conductive and insulating parts, so that the worker is maximally protected from accidental electric shock.

The high voltage system of an electrostatic gun can be classic or cascade in design. The classic scheme involves supplying high voltage through a cable from a source (high voltage transformer) to the gun. This makes the tool light and easy to use, since there are no electronics in the housing.

Mandatory short circuit protection. Such a spray is cheaper and easier to repair. The disadvantage of the classic scheme is the unstable voltage of the electrode, the lack of a switch on the nebulizer.

The cascade circuit implies the presence of a voltage converter built into the tool (directly in the atomizer). The gun is powered by 12 volts DC via a low voltage cable, and the voltage inside the tool is now raised to an acceptable level for operation.

The advantages of the cascade circuit are undeniable: stable voltage, uniformity of charging, the ability to adjust the voltage of the tool, the presence of a switch at hand. The disadvantages are greater weight and higher price.

Electrostatic paint systems are divided into automatic and manual. Both these and others can be, as noted above, airless, combined or pneumatic. In addition, the automatic ones are also disc high-speed, and the manual-cups are low-speed. We'll talk about that later.

In the usual case, spraying occurs as with traditional spray guns - airless, combination and pneumatic electrostatic sprayers work in the initial stage, but they provide economy of paint and a high transfer coefficient - up to 90% - due to the action of electrostatic forces.

But with atomizers and disks, everything happens a little differently: atomization occurs here due to centrifugal forces when the disk or cup rotates on the atomizer. The rotation is developed by the action of compressed air on the cup or disc and applied by electrostatic action. This achieves the transfer of up to 98% of the paint and varnish material.

Hand-held low-speed cup sprayers have a cup rotation speed of only 600 rpm and although they give 98% paint transfer, they are not very widely used in large industrial plants because their output is low, a maximum of 200 milliliters of paint per minute .

However, in small-scale industries, especially when painting metal grids, hand-held electrostatic sprayers are deservedly popular due to their economy and efficiency.

Automatic disc high-speed paint sprayers, with compressed air blowing around the periphery of the torch to narrow it, have a disc rotation speed of up to 60,000 rpm and have significantly higher productivity with high transfer efficiency (up to 90% ). Such electrostatic sprayers are widely used in industry, for example, in painting car body parts, household appliances, metal structures such as furniture, etc.

It has an electrostatic painting method and its own distinctive shades. First, it's a high-voltage job. Of course, the advantage of transferring up to 98% of the material is extremely important, but there are also traditional limitations here.

The paint and varnish material must have a certain minimum resistance so that it can be sufficiently charged after passing near the high-voltage electrode, otherwise the color quality will decrease, for example, the presence of metal dust in the composition of the enamel does not have the most - good effect on color quality.

Materials diluted with water are dangerous due to short circuit. Meanwhile, modern equipment does not stand still, it improves, and these limitations are no longer insurmountable obstacles to painting.

Separately, it should be said about the properties of the painted surfaces. Non-conductive materials, such as wood, plastic or rubber, cannot be painted simply, additional preliminary work is required. First, a conductive primer is applied or the material is moistened, then the paint is applied electrostatically.

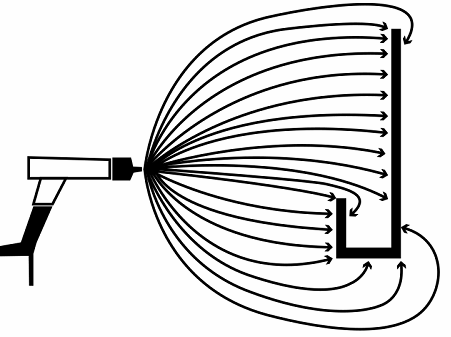

The shape of the object to be painted is also very important.Since the paint particles, charged and moving along the field line, rush towards the product mainly in the direction of its most charged areas, it will not be possible to paint over the voids or pockets, because there will be almost no electric field in them. the Faraday cage effect will work. On the contrary, sharp projections will be colored best, since the electric field strength near them will be the greatest.

However, there is a way out. Pockets and recesses can be painted, for this they simply turn off the high voltage and paint like a conventional pneumatic or airless spray gun. All these nuances are important to take into account.

Installations for electrostatic painting consist of the following parts: spray gun, high voltage source, hoses for various purposes (for air and for paint), power cable, grounding cable, pump, tank.

The installation must be reliably earthed before starting work. As a source of high voltage, both an electrical network and another source of energy can be used, in particular a mobile pneumatic constant voltage generator for autonomous operation of the installation in the absence of a conventional network.

It is worth noting that electrostatic painting technology has continuously improved over the decades since Ransburg invented his first electrostatic spray gun. Even today, electrostatic painting deservedly takes the place of the most economical technology for applying paints and varnishes, which achieves maximum transfer of the paint to the product.

Here, the amount of waste is minimized, so both in small-scale production and in large industrial enterprises, in factories, electrostatic painting is very popular today.