Industrial robots in modern production — types and devices

Industrial robots are widely used today in human production. They serve as one of the most effective means of mechanization and automation of transport and cargo operations, as well as many technological processes.

The positive effect of the introduction of industrial robots is usually noticed simultaneously from several sides: labor productivity increases, the quality of the final product improves, production costs decrease, working conditions for a person improve, and finally, the transition of an enterprise from the release of one type product in another is greatly facilitated.

However, in order to achieve such an extensive and multifaceted positive effect of the introduction of industrial robots on an already working manual production, it is necessary to calculate in advance the planned costs for the implementation process itself, for the price of the robot, and also to weigh whether the complexity of your production and technological process is generally adequate for the modernization plan to help install industrial robots.

In fact, sometimes initially production is so simplified that installing robots is simply impractical and even harmful. In addition, qualified personnel will be required for setup, maintenance, programming of robots, and in the process of work - auxiliary devices, etc. It is important to take this into account in advance.

One way or another, robotic unmanned solutions in production are becoming increasingly relevant today, if only because the harmful impact on human health is minimized. Let's add here the understanding that the full cycle of processing and installation is done faster, without breaks for smoke breaks and without errors inherent in any production where a living person acts instead of a robot. The human factor, after setting up the robots and starting the technological process, is practically excluded.

Today, manual labor is in most cases replaced by the labor of a robotic manipulator: tool grip, tool fixation, workpiece retention, feeding into the work area. Limitations are only imposed by: load capacity, limited working area, pre-programmed movements.

The industrial robot is able to provide:

-

high productivity thanks to fast and accurate positioning; better efficiency, since there is no need to pay salaries to the people he replaces, one operator is enough;

-

high quality — accuracy of the order of 0.05 mm, low probability of marriage;

-

safety for human health, for example, due to the fact that when painting, human contact with paints and varnishes is now excluded;

-

Finally, the working area of the robot is strictly limited and requires minimal maintenance, even if the working environment is chemically aggressive, the material of the robot will withstand this impact.

Historically, the first patented industrial robot was released in 1961 by Unimation Inc for the General Motors plant in New Jersey. The sequence of actions of the robot is recorded in the form of a code on a magnetic drum and performed in generalized coordinates. To perform actions, the robot uses hydraulic amplifiers. This technology was later transferred to the Japanese Kawasaki Heavy Industries and the English Guest, Keen and Nettlefolds. Thus, the production of robots by Unimation Inc expanded somewhat.

By 1970, Stanford University had developed the first robot that resembled the capabilities of a human arm with 6 degrees of freedom, which was controlled by a computer and had electric drives. At the same time, the Japanese company Nachi is developing it. Germany's KUKA Robotics would demonstrate the Famulus six-axis robot in 1973, and Switzerland's ABB Robotics would now begin selling the ASEA robot, also six-axis and electromechanically driven.

In 1974, the Japanese company Fanuc established its own production. In 1977, the first Yaskawa robot was produced.With the development of computer technology, robots are increasingly introduced into the automotive industry: in the early 1980s, General Motors invested forty billion dollars in the formation of its own factory automation system.

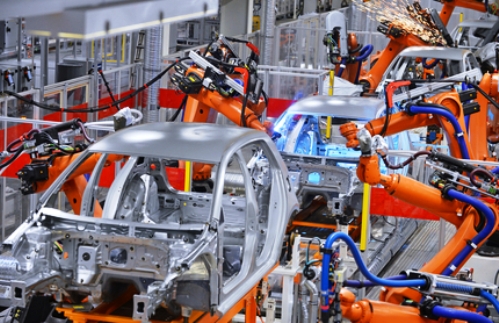

In 1984, domestic Avtovaz would acquire a license from KUKA Robotics and begin producing robots for its own production lines. Almost 70% of all robots in the world, by 1995, will be in Japan, its domestic market. In this way, industrial robots will finally establish themselves in the automotive industry.

How does automotive manufacturing go without welding? No way. So it turns out that all the automotive industries in the world are equipped with hundreds of robotic welding complexes. Every fifth industrial robot is involved in welding. The next demand is a robotic loader, but argon arc and spot welding come first.

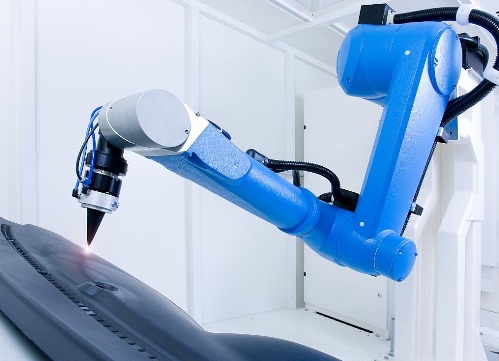

No manual welding can match the seam quality and degree of process control with a specialized robot. What about laser welding, where from a distance of up to 2 meters by means of a focused laser, the technological process is carried out with an accuracy of 0.2 mm — it is simply irreplaceable in aircraft construction and medicine. Add to that the integration with CAD / CAM digital systems.

The welding robot has three main operating units: a working body, a computer that controls the working body and memory. The working body is equipped with a hand-like handle. The body has freedom of movement along three axes (X, Y, Z), and the gripper itself can rotate around these axes. The robot itself can move along the guides.

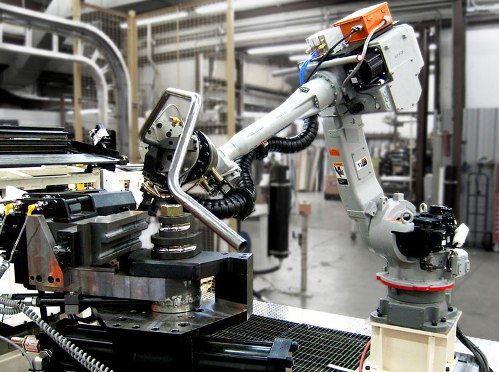

No modern production facility can do without unloading and loading, regardless of the size and weight of the products. The robot will independently install the workpiece into the machine, then unload and place it. A robot can interact with several machines simultaneously. Of course, we can't help but mention in this context the loading of luggage at the airport.

Robots already make it possible to reduce personnel costs to a minimum. It's not just about simple functions like punching or oven operation. Robots are capable of lifting more weights under much more difficult conditions, while not getting tired and spending significantly less time than a living person would.

In foundries and blacksmiths, for example, conditions are traditionally very difficult for people. This type of production is in third place after unloading and loading in terms of robotization. It is no coincidence that almost all European foundries are now equipped with automated systems with industrial robots. The cost of implementing a robot costs the enterprise hundreds of thousands of dollars, but a very flexible complex appears at its disposal, which is more than compensated.

Robotic laser and plasma cutting improve traditional lines with plasma torches. Three-dimensional cutting and cutting of corners and I-beams, preparation for further processing, welding, drilling. In the automotive industry, this technology is simply irreplaceable, since the edges of the products must be cut accurately and quickly after stamping and shaping.

One such robot can combine both welding and cutting.Productivity is increased by the introduction of waterjet cutting, which eliminates unnecessary exposure to heat on the material. Thus, in two and a half minutes, all the small holes in the metal of the Renault Espace coupes are cut in Renault's robotic plant in France.

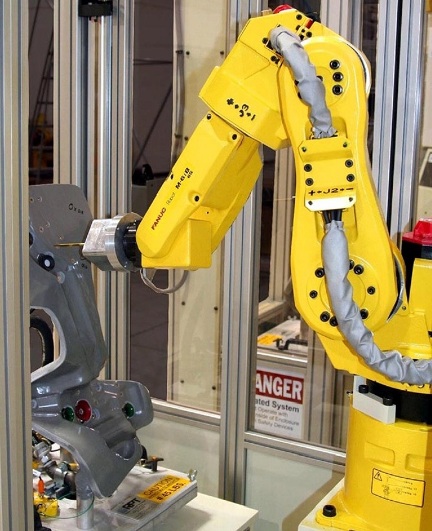

In the manufacture of furniture, automobiles and other products, robotic tube bending involving a workhead is useful when the tube is positioned by a robot and bent very quickly. Such a pipe can now be equipped with various elements that will not interfere with the process of bending the mandrels by the robot.

Edging, drilling and milling - what could be easier for a robot, whether it's metal, wood or plastic. Precise and durable manipulators handle these tasks with a bang. The working area is not limited, it is enough to install an extended axis or several controlled axes, which will give excellent flexibility plus high speed. One cannot do this.

The rotational frequencies of the milling tool reach tens of thousands of revolutions per minute, and the grinding of seams is completely transformed into a series of simple repetitive movements. But in the past, sanding and abrasive surface treatment was considered something dirty and heavy, and also very harmful. The paste is now fed automatically during felt wheel processing after passing the abrasive belt. Fast and safe for the operator.

The prospects for industrial robotics are enormous, as robots can fundamentally be introduced into almost any production process and in unlimited quantities.The quality of automatic work is sometimes so high that it is simply unattainable for human hands. There are entire large industries where errors and inaccuracies are unacceptable: aircraft manufacturing, precision medical equipment, ultra-precision weapons, etc. Not to mention the increase in the competitiveness of individual enterprises and the positive effect on their economy.