Application of hydraulics and pneumatics in industry

Since time immemorial, people have tried to use the properties of liquids and gases to accumulate, store, and transfer mechanical energy from its source to some mechanism that would do useful work.

The first such machines were mills. Water and windmills worked on dams capable of storing water, storing its potential energy, so that then man could use this energy for his needs. We can recall hydraulic wine presses — machines for producing wine starting material from grape bunches.

The first industrial revolution was about action under pressure. At the same time, the steam engine required the transmission of steam energy to various mechanisms, such as metal cutting machines, weaving machines, etc. The first transmissions were mechanical: gears, levers and long belts showed little efficiency, while they were difficult to control.

A little later, bulky structures began to be replaced by less bulky and safer in terms of injury, hydraulic and pneumatic transmissions, with the help of which energy can be transmitted to the executive organs of machines by exposure to a compressible liquid or gas under tremendous pressure.

This transition marks the beginning of a more efficient and flexible approach to controlling the movement of mechanisms. It became possible to smoothly change their speed, position tools more precisely, etc., without pulling them out to adjust torques and working forces.

The most important advantage of the hydraulic drive is the ability to achieve very high power densities. This refers to the power per unit weight of the machine. More modern hydraulic devices now include electronic control, which allows expanding the functionality and increasing the power, so that the amplification factors today already reach about 100,000.

The field of industrial application of hydraulics and pneumatics in the modern world is very wide and diverse. Here you can find metallurgical production, construction, medical equipment and much, much more. Let's look at just a few examples of the current implementation of the technology, as simple as it seems at first glance.

Metallurgical production is based entirely on hydraulics. Hydraulic elevators, rotary units, cranes, manipulators, lifting and rocking tables, chutes, roll control systems of roller mills, transport and sorting devices are used everywhere here.

Hydraulics together with pneumatics are an essential attribute metal cutting machines… The hydraulic drive allows for precise, high-power machine operations. It provides high performance with small dimensions and optimal weight.

You cannot do without hydraulic drive in powerful forging and pressing mechanisms. The forging press, for example, uses in its work a compression force of up to 120,000 kgf, which is simply unattainable without the use of hydraulics.

Old car bodies are pressed into packages and cut using a special hydraulic device. Here, loading, vertical and horizontal compression, pushing on a conveyor and loading of finished packages are carried out only thanks to hydraulic devices.

Plastic products: bottles, cases for mobile gadgets and household appliances, various interior items, etc., are created by the thousands only thanks to injection molding, which is possible only with the help of hydraulic drive.

It is impossible not to mention modern construction equipment. The high power density required here is only achieved with hydraulics. A vivid example of such a technique is a hydraulic excavator.

Cranes used in the handling behavior of construction sites and especially in ports must perform all operations very quickly and accurately. These cranes use hydraulics, resulting in high jib mobility and proper main frame rotation speed capable of rapid lifting.

Industrial robots — a special field of application of the hydraulic drive. These robots successfully carry out painting and welding, for example, during the automated assembly of cars.In factories, such robots serve presses, metal cutting machines, forging hammers, etc.

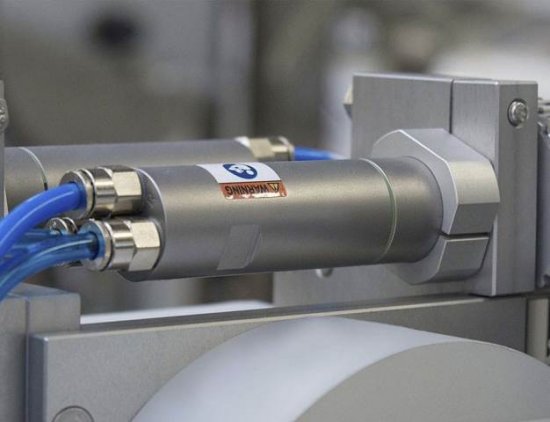

Pneumatics should be highlighted separately. Its industrial applicability is extremely diverse, as the energy of compressed air proves to be indispensable in some cases where it is required to actuate the working bodies of machines and mechanisms very quickly, especially in automated production.

Only the pneumatic actuator can perform some of the impact operations. It is he who works in the braking systems of railways and heavy vehicles. The advantage of pneumatics compared to hydraulics is that the supply of the working fluid is unlimited.

In addition, the discharge of compressed air is not necessary. In addition, gas is easy to transport, often there is no danger of fire. It is pneumatic devices that are often the only ones acceptable in the mining, gas and woodworking industries.

The advantages of pneumatic units are clearly manifested in automated mechanical systems where there is a need to quickly perform such repetitive operations as fixing and clamping, marking and spot welding, packaging, transportation and control of the linear dimensions of parts. Also, pneumatic manipulators are the most widely used today as part of loading and unloading robotic systems.

According to German statistics, pneumatics in many automation equipment has recently attracted more and more capital investment.Experts agree that it is the pneumatic drive in production automation that provides the optimal combination of low operating costs with intelligent control electronics — the foundation mechatronic systems of the future… In fact, although many tasks have already been solved using pneumatics and hydraulics, there are still many technological challenges ahead for engineers and developers.

See also: Pneumatic devices of mechatronic systems