Stepper motor driver - device, types and capabilities

Stepper motors are used in many industrial applications today. Engines of this type are distinguished by the fact that they allow to achieve high accuracy of positioning of the working body, compared to other types of engines. Clearly, precise automatic control is required for the stepper motor to operate. For this purpose, they serve as stepper motor controllers, ensuring continuous and accurate operation of electric drives for various purposes.

Roughly, the principle of operation of a stepper motor can be described as follows. Each full rotation of the rotor of a stepper motor consists of several steps. Most stepper motors are designed for 1.8 degree steps and there are 200 steps per full revolution. The drive changes its step position when a supply voltage is applied to a particular stator winding. The direction of rotation depends on the direction of the current in the coil.

The next step is to turn off the first winding, power is supplied to the second and so on, as a result, after each winding is worked out, the rotor will make a full rotation. But this is a rough description, actually the algorithms are a bit more complicated and this will be discussed later.

Stepper Motor Control Algorithms

Stepper motor control can be implemented according to one of four basic algorithms: variable phase switching, phase overlap control, half-step control, or microstep control.

In the first case, at any instant of time only one of the phases receives power, and the equilibrium points of the motor rotor at each step coincide with the key equilibrium points—the poles are clearly defined.

Phase overlap control allows the rotor to step to positions between the stator poles, which increases torque by 40% compared to non-phase overlap control. The angle of inclination is maintained, but the lock position is shifted — it is located between the crests of the stator poles. These first two algorithms are used in electrical equipment where very high accuracy is not required.

Half-step control is a combination of the first two algorithms: one phase (winding) or two are powered by a step. The step size is halved, the positioning accuracy is higher and the probability of mechanical resonance in the motor is reduced.

And finally, the micro level mode.Here, the current in the phases changes in magnitude so that the position of the rotor fixation per step falls on the point between the poles, and depending on the ratio of the currents in the simultaneously connected phases, several such steps can be obtained. By adjusting the ratio of currents, by adjusting the number of working ratios, microsteps are obtained — the most accurate positioning of the rotor.

See more details with schematics here: Stepper motor control

Stepper motor driver

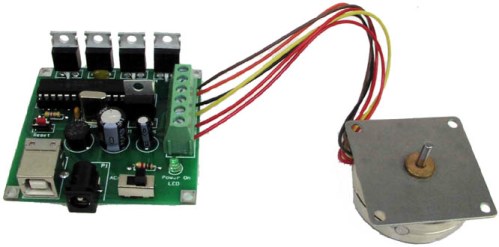

To put the chosen algorithm into practice, implement a stepper motor driver… The driver contains a power supply and a controller section.

The power part of the driver is solid state power amplifier, whose task is to convert the pulses of current applied to the phases into movements of the rotor: one pulse — one exact step or microdegree.

Direction and magnitude of the current — the direction and size of the step. That is, the task of the power unit is to supply a current of a certain magnitude and direction to the corresponding stator winding, to hold this current for some time, and also to quickly turn on and off currents, so the speed and power characteristics of the device match the task at hand.

The more perfect the power part of the drive mechanism, the greater torque can be obtained on the shaft. In general, the progress trend in the improvement of stepper motors and their drivers is to obtain significant operating torque from motors with small dimensions, high precision, and at the same time maintain high efficiency.

Stepper motor controller

The stepper motor controller is an intelligent part of the system, which is usually made on the basis of a reprogrammable microcontroller. The controller is responsible for at what time, to which coil, for how long and how much current will be supplied. The controller controls the operation of the driver's power unit.

Advanced controllers are connected to a computer and can be adjusted in real time using a computer. The ability to repeatedly reprogram the microcontroller frees the user from the need to buy a new controller every time the task is adjusted — it is enough to reconfigure the existing one, this is the flexibility, the controller can be easily reoriented programmatically to perform new functions.

There are a wide range of stepper motor controllers on the market today from various manufacturers that feature expandable features. Programmable controllers imply the recording of programs, and some include programmable logic blocks, with which it is possible to flexibly configure the algorithm for controlling the stepper motor for a certain technological process.

Controller capabilities

Stepper motor control with a controller allows high accuracy up to 20,000 micro steps per revolution. In addition, management can be carried out both directly from a computer and due to a program sewn into the device or through a program from a memory card. If the parameters change during the execution of the task, the computer can interrogate the sensors, monitor the changing parameters and quickly change the operation mode of the stepper motor.

There are commercially available stepper motor control blocks that are connected to: current source, control buttons, clock source, step potentiometer, etc. Such blocks allow you to quickly integrate a stepper motor into equipment to perform of repetitive cyclic tasks with manual or automatic control ... The ability to synchronize with external devices and support for automatic on, off and control is an indisputable advantage of the stepper motor control unit.

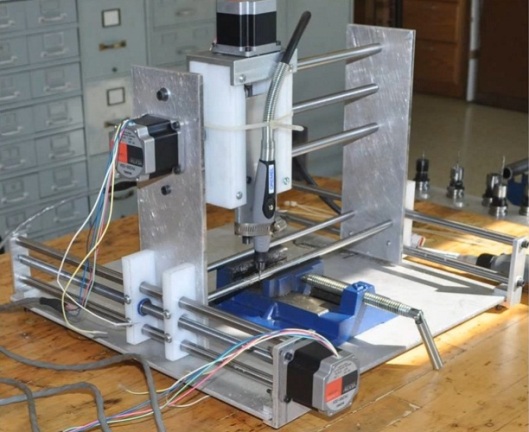

The device can be controlled directly from a computer if, for example, you want to run a program for CNC machine, or in manual mode without additional external control, that is, autonomously, when the direction of rotation of the stepper motor shaft is set by the reverse sensor, and the speed is controlled by a potentiometer. The control device is selected according to the parameters of the stepper motor to be used.

Depending on the nature of the goal, the stepper motor control method is selected. If you need to set up a simple low-power electric drive control where one pulse is applied to one stator winding each time: for a full revolution, say 48 steps, and the rotor will move 7.5 degrees with each step. Single pulse mode is fine in this case.

To achieve a higher torque, a double pulse is used - it is fed to two adjacent coils at the same time per pulse. And if 48 steps are needed for a full revolution, then again 48 such double pulses are needed, each will result in a step of 7 .5 degrees, but with 40% more torque than in single pulse mode.By combining the two methods you can get 96 pulses by dividing the steps — you get 3.75 degrees per step — this is a combined (half step) control mode.