Choice of number and power of transformers

The correct selection of the number and capacity of transformers in substations of industrial enterprises is one of the important issues of power supply and the construction of rational networks. Under normal conditions, the transformers must supply power to all users of the enterprise at their rated load.

The correct selection of the number and capacity of transformers in substations of industrial enterprises is one of the important issues of power supply and the construction of rational networks. Under normal conditions, the transformers must supply power to all users of the enterprise at their rated load.

The number of transformers in the substation is determined by the requirement of power supply reliability. In this approach, the best option is to install two transformers, providing uninterrupted power supply. workshop users of any category… However, if only category II and III receivers are installed in the service, then usually the more economical single transformer substations.

When designing networks in an installation, the installation of single-transformer substations is carried out in the event that shorting of consumers is provided through the low-voltage network, as well as when it is possible to replace a damaged transformer within a certain time.

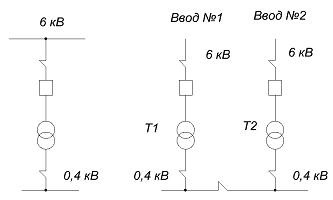

Rice. 1 Workshop power supply schemes with one (a) and two (b) transformers

Two-transformer substations are used with a significant number of users of category II or in the presence of users of category I. In addition, two-transformer substations with an uneven daily and annual load schedule of an enterprise, with a seasonal mode of operation with a significant difference in shift load, are recommended. Then, when the load decreases, one of the transformers is switched off.

The problem of choosing the number of transformers consists in choosing between two options (Fig. 1 a and b) the option with the best technical and economic indicators. The optimal version of the power scheme is selected based on a comparison of the reduced annual costs for each option:

Γi = Ce, i + kn, eKi + Yi,

where Ce, i — operating costs of the i -th option, kn, e — standard efficiency factor, Ki — capital costs for the i -th option, Ui — losses of consumers from interruption of power supply.

It should be noted that in the case of fig. 1 (a), there is a complete power failure and here the supply of consumers through a backup line for voltage 0.4 kV cannot be taken into account, since such a circuit is similar to a two-transformer circuit, but with a worse performance due to a long line from 0.4 kV...

It should be noted that in the case of fig. 1 (a), there is a complete power failure and here the supply of consumers through a backup line for voltage 0.4 kV cannot be taken into account, since such a circuit is similar to a two-transformer circuit, but with a worse performance due to a long line from 0.4 kV...

When comparing options, the question of the future development of the enterprise plays an important role. So, for example, if there are currently only users from the second category in the store, then it makes sense to consider options. But if after a year it is planned to re-equip the production and first-category consumers appear in the store, then, of course, it is necessary to choose the option with two transformers.

In principle, the installation of two transformers provides reliable power supply to consumers. This means that if one transformer is damaged, the second one, taking into account its overload capacity, ensures 100% reliability of the power supply during the time required to repair the transformer.

But there are cases when the power of the existing two transformers becomes insufficient to provide power to all receivers, for example, when installing more powerful equipment, changing the mode of operation of electrical receivers, etc. Options for installing more powerful transformers in the substation or installing a third transformer to cover the increased power are then considered.

The second option seems to be preferable, since the reliability of the substation increases, there is no need to sell old transformers, and the capital cost of installing a third transformer is, as a rule, much less than when re-equipping the entire substation.

The second option seems to be preferable, since the reliability of the substation increases, there is no need to sell old transformers, and the capital cost of installing a third transformer is, as a rule, much less than when re-equipping the entire substation.

But this option is not always possible, for example, with dense development of the territory of the enterprise, there simply may not be enough space for an additional transformer. On the other hand, there is considerable circuit complexity that may not be possible when the transformers are operating in parallel. Therefore, consideration of the options is carried out on a case-by-case basis.

In addition to reliability requirements, when choosing the number of transformers, the mode of operation of the receivers should be taken into account. For example, with a low load curve fill factor, it is economically possible to install not one but two transformers.

On large transformer substations, GPP, as a rule, the number of transformers is selected no more than two. This is mainly due to the fact that the cost of switching equipment on the higher voltage side of the enterprise is comparable to the cost of a transformer.

Selection of transformers by power

It is recommended to select the power of GPP transformers and workshop transformers (except in cases of sharply variable load schedule), it is recommended to select the average load for the busiest shift, followed by checking and adjusting according to the specific power consumption of a unit of production obtained as a result of studies of the electrical loads of enterprises.

For continuous supply of loads of the first and second category, it is recommended to install two transformers with a load factor in normal mode of 0.6 — 0.7 per GPP of industrial enterprises.

It is recommended to take the following load factors for transformers of commercial substations: double-transformer with predominant load of the first category — 0.65 — 0.7, single-transformer with predominant load of the second category and redundancy for the secondary voltage jumpers — 0.7 — 0.8.

The number and capacity of workshop transformers should be selected based on technical and economic calculations. At the same time, in a first approximation, the power of transformers in networks with a voltage of 380 V can be taken based on the following specific load densities: up to 1000 kVA at densities up to 0.2 kV-A / m2, 1600 kVA at densities of 0 ,2 — 0.3 kVA / m2, 1600 — 2500 kVA at densities 0.3 kVA / m2 and more.

Scale of standard powers of power transformers

In our country, a single scale of transformer capacities has been adopted. Choosing a rational scale is one of the main tasks in optimizing industrial power systems. Today there are two power scales: with a step of 1.35 and with a step of 1.6. That is, the first scale includes powers: 100, 135, 180, 240, 320, 420, 560 kVA, etc., and the second includes 100, 160, 250, 400, 630, 1000 kVA, etc. Transformers of the first scale of power they are currently not produced and are used on already existing transformer substations, and the second power scale is used for the design of new transformer substations.

It should be noted that the scale with a coefficient of 1.35 is more advantageous in terms of transformer loading. For example, when two transformers are operating with a load factor of 0.7, when one of them is switched off, the other is overloaded by 30%. This mode of operation meets the requirements of the operating conditions of the transformer. In this way, its power can be fully utilized.

It should be noted that the scale with a coefficient of 1.35 is more advantageous in terms of transformer loading. For example, when two transformers are operating with a load factor of 0.7, when one of them is switched off, the other is overloaded by 30%. This mode of operation meets the requirements of the operating conditions of the transformer. In this way, its power can be fully utilized.

At an allowable overload of 40%, underutilization of the installed power of transformers with a scale of 1.6 occurs.

Suppose that two transformers of the transformer substation are working separately and the load of each is 80 kVA, when one of them is disconnected, the second one must provide a load of 160 kVA. The option of installing two transformers of 100 kVA cannot be accepted, as in this case the overload will be 60% when one transformer is out of service. When installing 160 kVA transformers, this results in their load in normal mode by only 50%.

When using a scale with a step of 1.35, you can install transformers with a capacity of 135 kVA, then their load in normal mode will be 70%, and in emergency overload it will be no more than 40%.

Based on this example, you can see that a scale with a step of 1.35 is more rational. And about 20% of the power of the transformers produced is not used. A possible solution to this problem is the installation of two transformers at a transformer substation with different power. However, this solution cannot be considered technically rational, because when a transformer with a higher power is taken out of service, the remaining transformer will not cover the entire load of the workshop.

A natural question arises: what is the reason for moving to a new set of capacities? The answer obviously lies in reducing the variety of capacities to unify equipment: not only transformers, but also in close proximity to it (switches, load break switches, disconnectors etc.).

Based on all that has been said, the selection of the number and power of transformers for powering factory substations is carried out as follows:

1) the number of transformers of the transformer substation is determined based on the reliability of the power supply, taking into account the category of receivers;

2) the closest options for powering the selected transformers (no more than three) are selected, taking into account their permissible load in normal mode and permissible overload in emergency mode;

3) an economically feasible solution is determined by the outlined options, acceptable for specific conditions;

4) the possibility of expansion or development of the transformer substation is taken into account and the question of the possible installation of more powerful transformers on the same foundations is considered or the possibility of expanding the substation by increasing the number of transformers is envisaged.