Trenchless cable installation in the ground

Laying of a trenchless cable is allowed for a single armored cable with a voltage of up to 10 kV with a lead or aluminum sheath in open areas, on sections of cable routes remote from underground engineering structures. In urban power transmission networks and on the territories of industrial enterprises, in areas with underground communications and intersections with engineering structures, the laying of cables without trenches is prohibited.

Laying of a trenchless cable is allowed for a single armored cable with a voltage of up to 10 kV with a lead or aluminum sheath in open areas, on sections of cable routes remote from underground engineering structures. In urban power transmission networks and on the territories of industrial enterprises, in areas with underground communications and intersections with engineering structures, the laying of cables without trenches is prohibited.

In the case of bare laying, the cable is laid at a depth of 1-1.2 m from the ground level. There is no need for beds, shallow earth powder and mechanical protection of the cable, which provides a 7-8 times reduction in labor intensity compared to laying in an open trench. The cable is filled with soil cut by the blade of the cable laying machine as it moves.

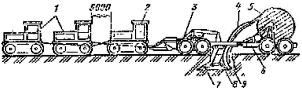

Trenchless laying is carried out by a self-propelled or mobile cable-laying machine with a knife (Fig. 1), which provides the ability to lay in all soil categories, crossing swamps, ravines and narrow water obstacles. Before laying, the drum with the cable is installed on the cable layer.

The cable is unwound from the drum manually during the laying process, depending on the movement speed of the mechanism, so that the cable in front of the entrance and the cassette of the cable layer is not stretched and there is some slack. To avoid cable damage, the cable layer must move smoothly along the track without sudden shocks or stops.

Rice. 1. Cable laying by cable laying machine: 1 — tractor type. T-100 M; 2 — tractor type T-100 MEG, 3 — cable layer type KU-150; 4 — cassette input, 5 — cable drum; 6 — cable conveyor type TK 5; 7 — knife; 8 — cable cassette; 9 — cable

When laying with a measuring rail, the deepening of the cable in the ground is controlled every 20-50 m. The deviation of the cable laying depth from the design is allowed within ± 50 mm.

When laying, it is necessary to take into account the structural length of the cables on the drums, so that the connectors are located in places convenient for installation and operation.

Before the end of unwinding the cable from one drum, its end is overlapped and fixed with resin tape to the end of the cable of another drum prepared for laying. The length of the overlap should be 2 m.